Method for directly producing metal bismuth by performing reduction and sulfur-fixed roasting on bismuth sulfide material

A technology of bismuth sulfide and roasting products, which is applied in the field of non-ferrous metal metallurgy, can solve the problems of inability to use valuable metals at the same time, pollute the environment by flue gas, and consume large reagents, and achieve stable properties, simple operation and control, and non-toxic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

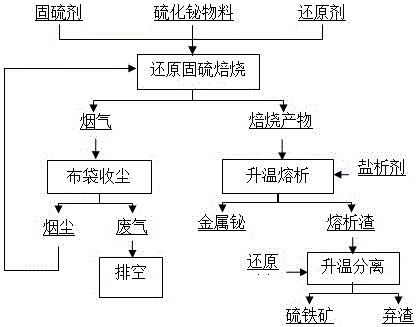

[0046] Process flow chart of the present invention is attached figure 1 shown.

[0047] The main chemical components (wt.%) of the bismuth sulfide material used as the test raw material in this example are: Bi 25.18, Fe19.33, S 21.25, Al 1.46, Ca 3.30, Cu 1.99, Mo 2.23, Pb 2.78, SiO 2 12.67; the chemical composition of pyrite slag is (wt.%): Fe 71.30, S 1.72, Zn 1.28, SiO 2 10.57, CaO 2.14, Ag 850g / t; the chemical composition (wt.%) of iron oxide concentrate is: Fe 2 o 3 89.30, SiO 2 4.42, CaO 1.14, Al 2 o 3 1.81, MgO 0.29; the chemical composition (wt. %) of reduced coal powder is: C 82.33, S 2.01, SiO 2 6.66, CaO 0.83, Al 2 o 3 4.81, MgO 0.23; the chemical composition (wt. %) of the reduced coke powder is C 85.73, S 2.23, and ash 11.03.

[0048] S1. Weigh 100g of bismuth sulfide material, 32g of pyrite slag, and 10g of coal powder with the above ingredients, mix them evenly, put them into a graphite crucible, put them into an electric furnace and roast at 700...

Embodiment 2

[0053] Test raw materials, reagents and steps are the same as in Example 1.

[0054] Weigh 100g of bismuth sulfide material (concentrate), 32g of pyrite slag, and 10g of coal powder with the above ingredients, mix them uniformly, put them into a graphite crucible, put them into an electric furnace and roast at 750°C for 2.0h. After cooling, 127.42 g of roasted products were obtained, the main components being Bi 18.29%, Fe 31.02%, and S 13.97%. XRD and phase analysis show that metal bismuth accounts for 93.11% of the total bismuth in the bismuth phase, the iron phase is mainly FeS, and the calculated sulfur fixation rate is 85.74%. After adding 3g of KCl to the roasted product, the temperature was raised rapidly to 1000°C and held for 0.5h. After cooling, the metal and solid slag were separated to obtain 25.26g of crude metal bismuth, which contained 96.22% of bismuth after analysis, and the direct yield of bismuth was calculated to be 96.51%.

[0055] After adding 3g of coal...

Embodiment 3

[0058] Test raw materials, reagents and steps are the same as in Example 1.

[0059] Weigh 100g of bismuth sulfide material (concentrate), 32g of iron oxide concentrate, and 10g of coke powder with the above ingredients, mix them uniformly, put them into a graphite crucible, and put them into an electric furnace for 2.0 hours at 400°C. After cooling, 127.42 g of roasted products were obtained, the main components of which were Bi 18.75%, Fe 30.66%, and S 14.39%. The phase analysis shows that metal bismuth accounts for 55.82% of the total bismuth in the bismuth phase, the sulfur phase is mainly FeS, and the calculated sulfur fixation rate is 82.43%. After adding 3g NaCl to the roasted product, the temperature was raised rapidly to 800°C and held for 2 hours. After cooling, the metal and solid slag were separated to obtain 22.35g of crude metal bismuth, which contained 93.37% of bismuth after analysis, and the direct yield of bismuth was calculated to be 82.86%.

[0060] After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com