Press-fit manufacturing equipment for integrally forming datura stramonium

A kind of manufacturing equipment, mandolin technology, applied in the field of musical instrument processing, can solve the problems of ineffective guarantee of product quality, a large number of manual operations, and low production efficiency of products, so as to improve the overall quality and production efficiency, ensure the quality of transmission, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the specific embodiments of the present invention are described in detail below with reference to the accompanying drawings.

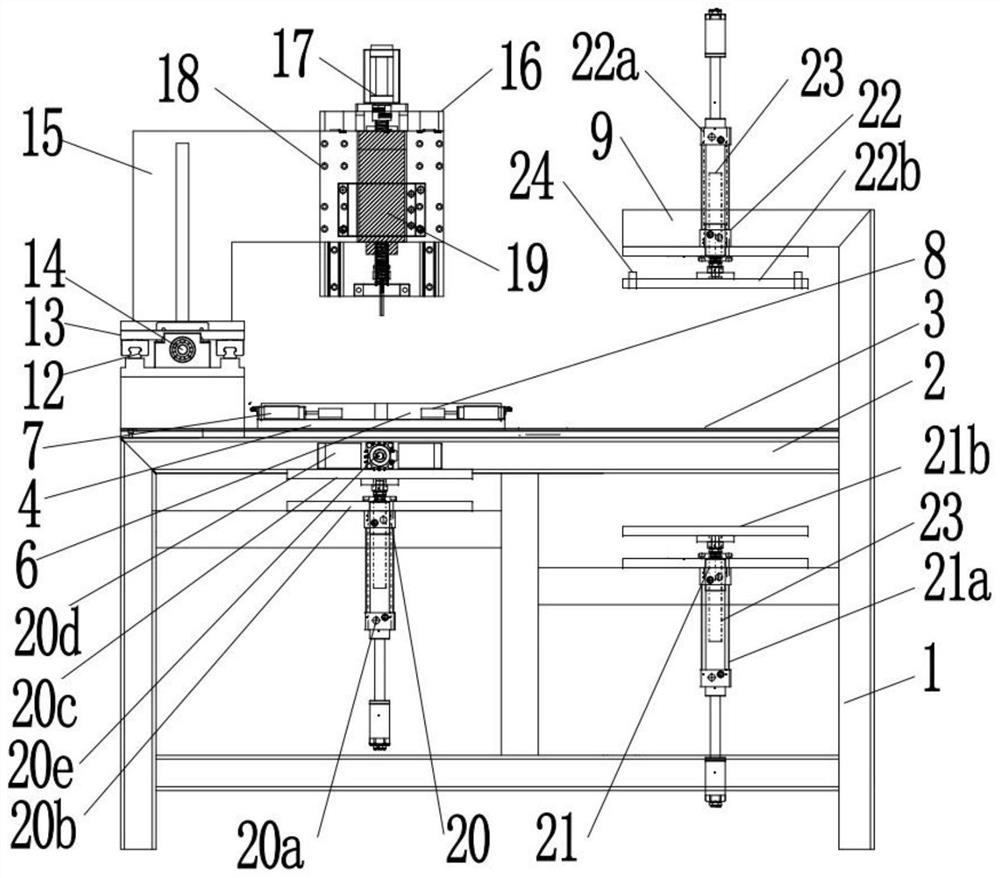

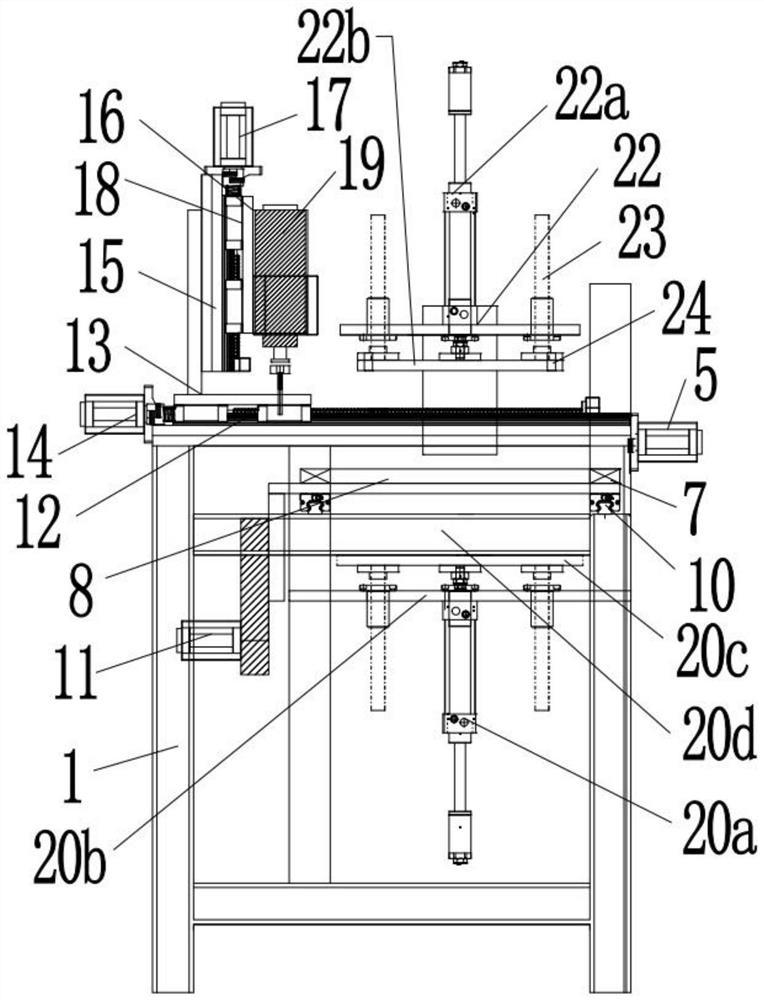

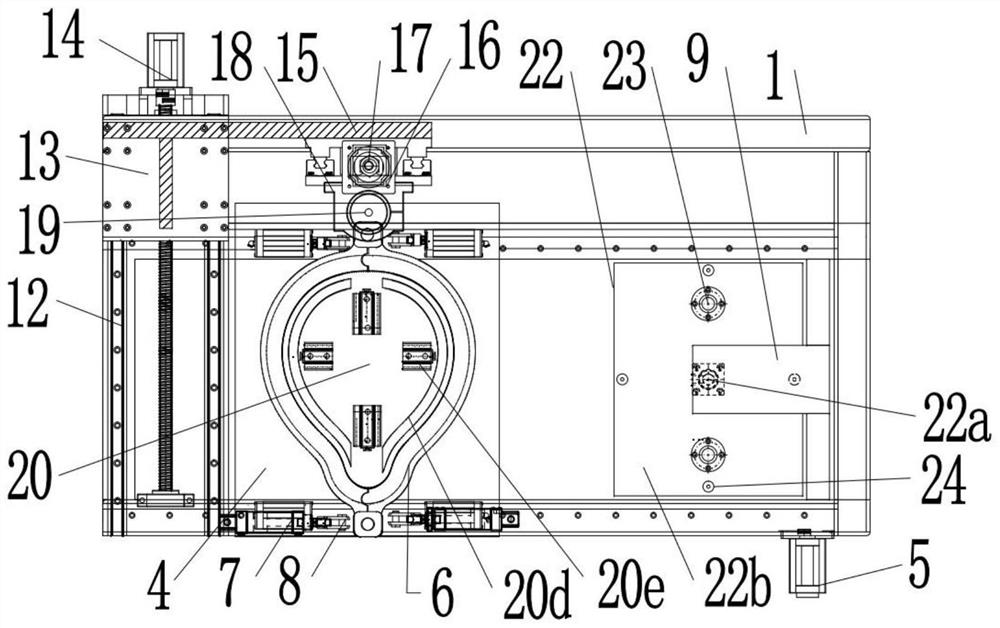

[0017] like Figures 1 to 3 The mandolin integrally formed pressing manufacturing equipment includes a frame assembly 1, a back plate pressing mechanism 21, a panel pressing mechanism 22 and a molding mechanism 20, and a back plate pressing mechanism is arranged in the lower part of the frame assembly 1. Mechanism 21, molding mechanism 20, a panel pressing mechanism 22 is set on the top, the top of the frame assembly 1 is a workbench 2, and two conveying guide rails 3 are symmetrically arranged on the table surface of the workbench 2 along its transverse axis direction. The conveying guide rail 3 is provided with a material carrier 4 that slides with it, and a material drive 5 is arranged at either end of the conveying guide 3 to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com