Hot melt ink comprising a mixture of dyes

A technology of dyes and compositions, applied in inks, household utensils, applications, etc., can solve the problems of color imprinting and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Example 1 is an ink composition of the present invention.

Embodiment 2

[0009] Example 2 is another ink composition of the present invention.

Embodiment 3

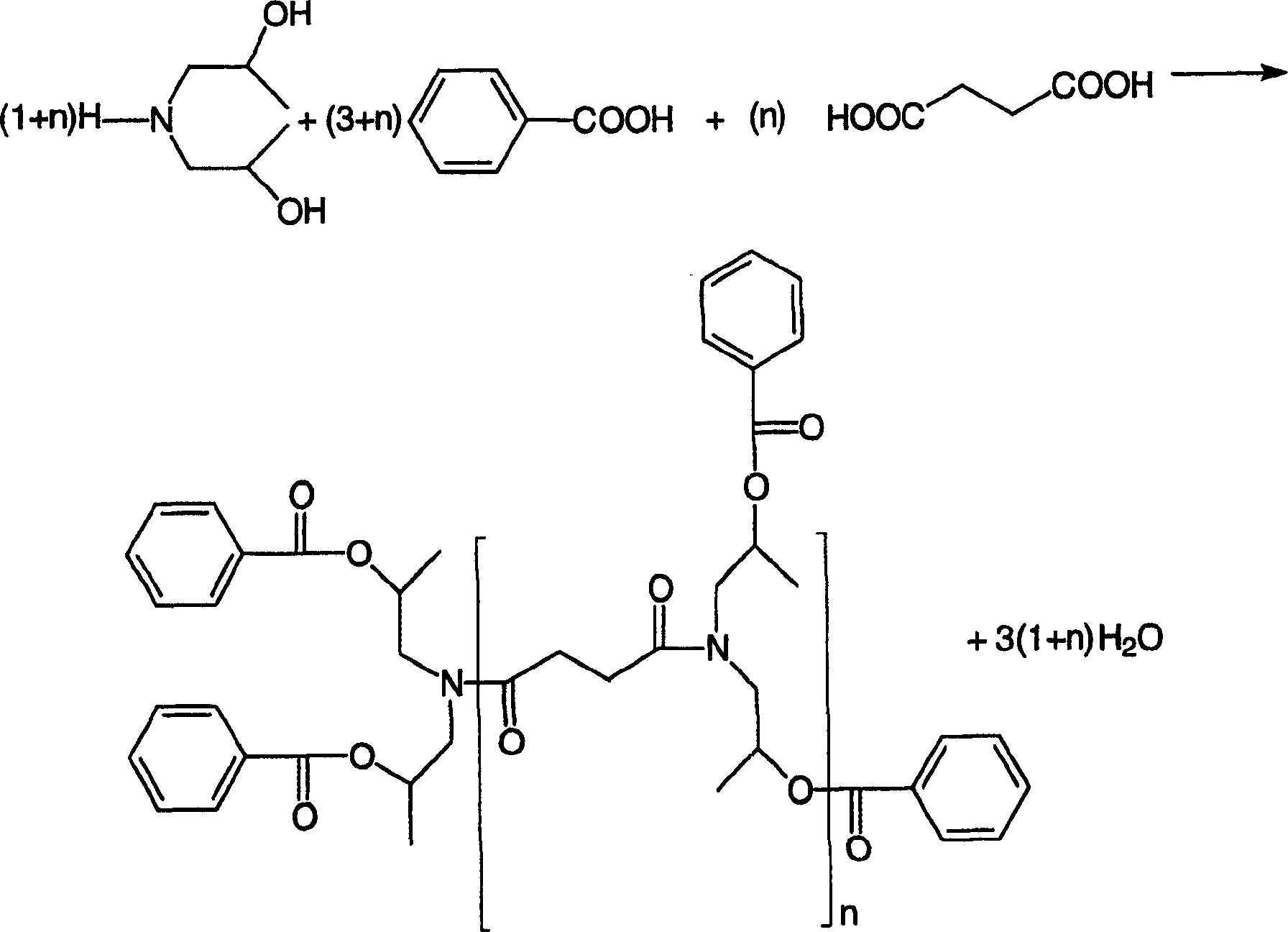

[0010] Example 3 is the preparation of the binder used in the carrier composition.

[0011] Example 1

[0012] The hot melt ink of the present invention is based on a carrier composition comprising 65% by weight of a diester formed from the reaction of 1,4-dimethanol-transcyclohexane with 2 molar equivalents of orthotoluic acid. This compound, known as Cyclo-2T, is known from EP1067157 (compound 17 in Table 2, D). The carrier composition also contained 35% by weight of an amorphous component, which is a mixture of different compounds. Example 3 describes how to obtain this amorphous component. The dyes added were 1.125 g CI Solvent Red 172 and 1.125 g CI Solvent Red 149 per 100 g of carrier composition. CI solvent red 172 was purchased from Messrs Buckeye under the trade name LambdaPlast RedL2B. The dyes are known as Morplus Magenta36 and Xindasol Red 172. CI Solvent Red 149 was purchased from MessrsBuckeye under the trade name LambdaPlast FL Red FGA. The dye is known by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com