Single-component polyurea coating and preparation method thereof

A technology of coating and polyurea, which is applied in the field of one-component polyurea coating and its preparation, can solve the problems of limitation, poor bonding force between coating and substrate, low tensile strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 50ml of amino-terminated polyether (product of Yangzhou Chenhua Technology Group Co., Ltd., number-average molecular weight is 2000) in a four-necked flask with agitator, thermometer, dropping funnel, and reflux condenser, then use the dropping funnel to drop Add 55-57ml of cyclobutanone (product of Shanghai Lingfeng Chemical Reagent Co., Ltd., chemically pure), and then add 15ml of polyamine (diethylenetriamine, product of Shanghai Lingfeng Chemical Reagent Co., Ltd., chemically pure) solution to promote chain extension The reaction proceeds. While adding the solution dropwise, stir with a glass rod, heat in a water bath to control the reaction temperature at 80°C, and control the dropping rate below 2ml / min. After the dropwise addition is completed, keep warm and reflux for 30 minutes. When the solution gradually turns into a light yellow liquid accompanied by the generation of ammonia-like gas, it indicates that ketimine is formed and the terminal amino group has...

Embodiment 2

[0031] Polyurea coating performance test method

[0032] (1) Tensile test

[0033] Laboratory equipment

[0034]Tensile testing machine: Jiangsu Mingzhu Experimental Machinery Co., Ltd. MZ-4000D electronic universal testing machine, the displacement measurement accuracy is within ±0.5% of the indicated value, the deformation measurement accuracy is within ±0.5% of the indicated value, and the effective stretching distance is 900mm. The stretching speed is 6mm / min-500mm / min. Slicer: cut the type I dumbbells that meet the requirements of GB / T 528-1998 test pieces. Thickness gauge: pressure (100 ± 10) g, measuring surface diameter (10 ± 1) mm, minimum graduation 0.01 mm. Vernier caliper: accuracy ± 0.02mm.

[0035] experimental method

[0036] Cut 6 dumbbell-shaped specimens, place the specimens under standard conditions for at least 2 hours, then draw two parallel marking lines with a distance of 65mm on the specimens with a ruler, and measure the middle and both ends of th...

Embodiment 3

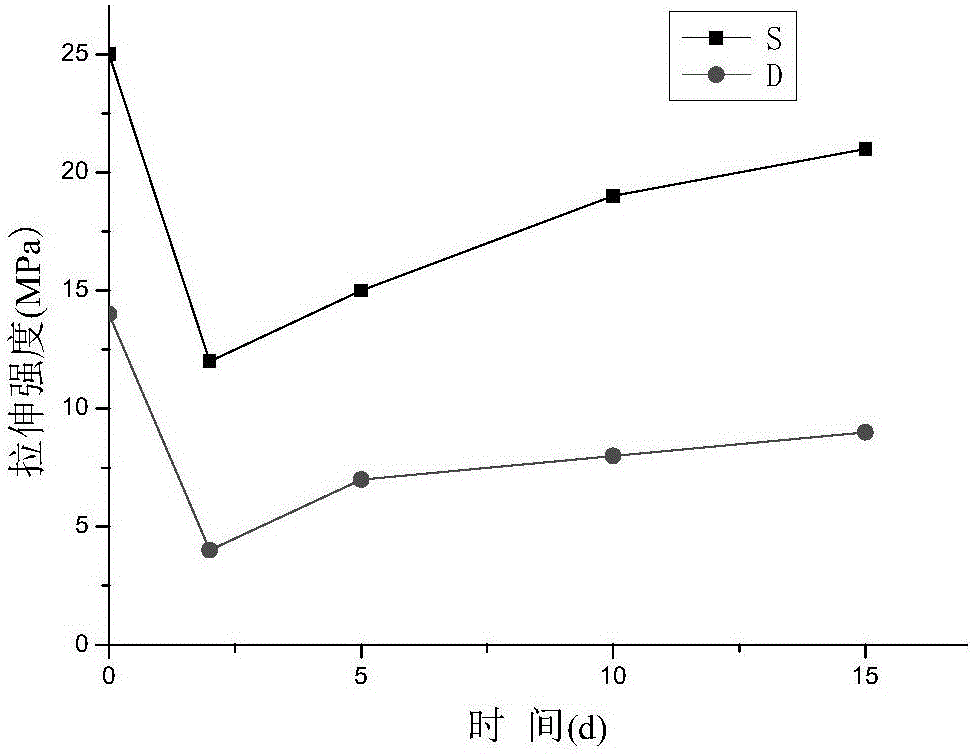

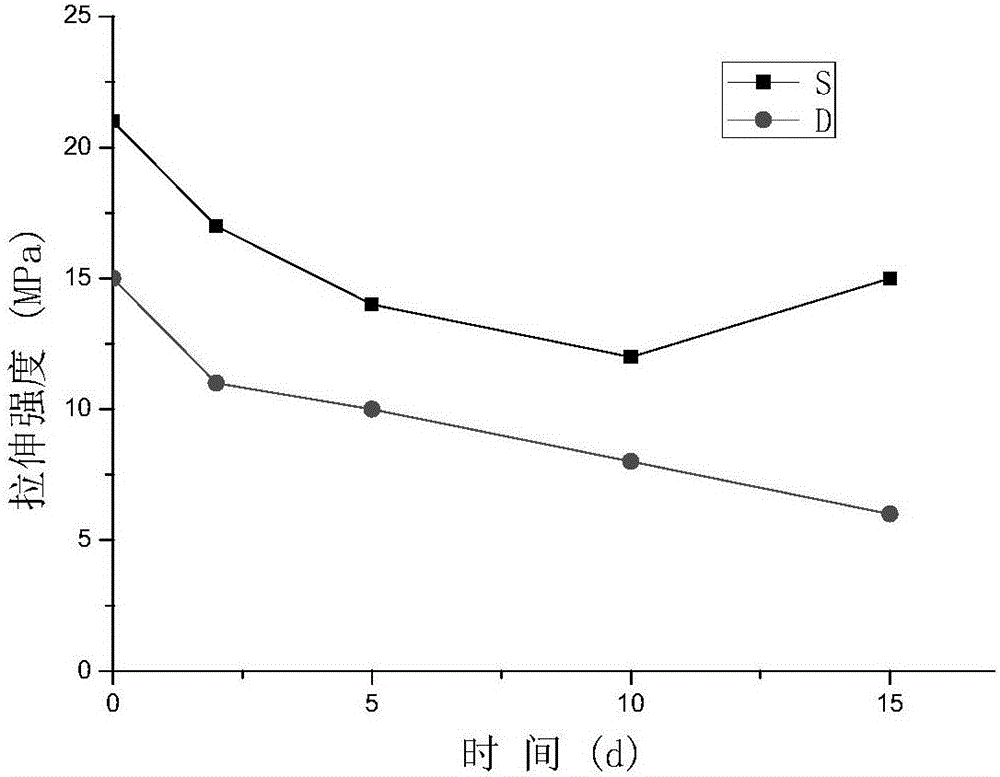

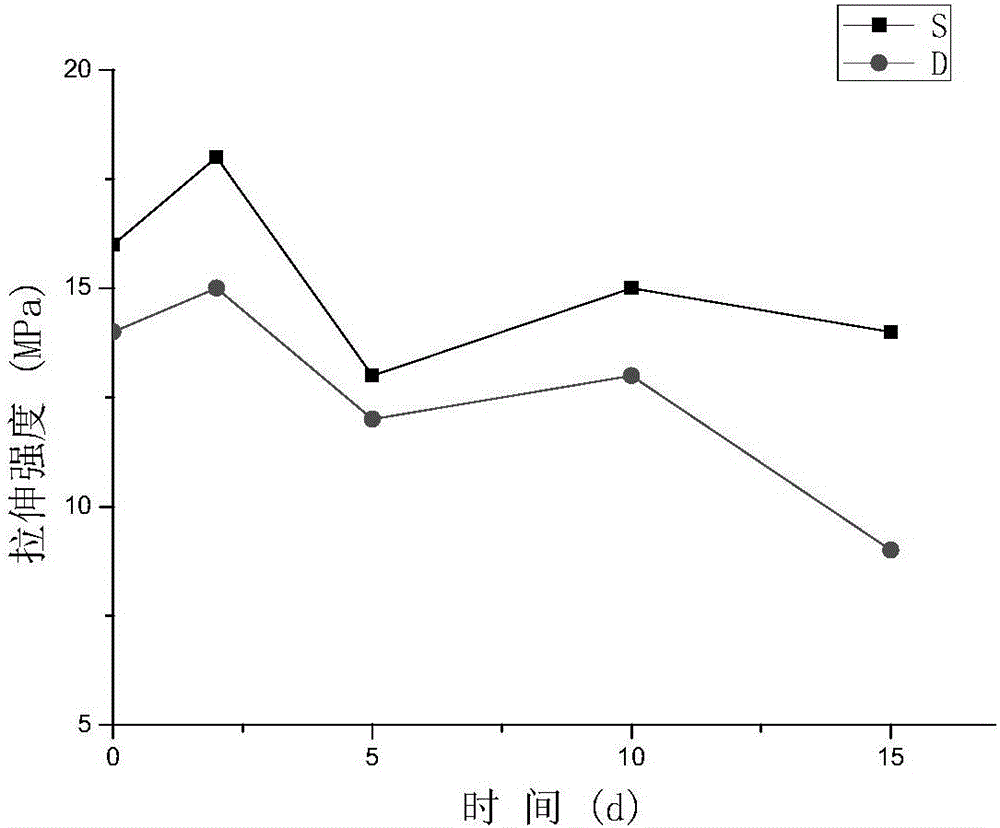

[0066] The polyurea coating performance test result that embodiment 1 makes

[0067] (1) Experimental results of physical performance test of single-component polyurea coating material

[0068] The performance of the one-component polyurea sample prepared by cyclobutanone modification and the conventional two-component polyurea sample is compared, and the results are shown in Table 1.

[0069] Table 1 Comparison of relative properties between one-component polyurea of the present invention and two-component polyurea samples

[0070] project Two-component polyurea One-component polyurea of the present invention Solid content 83 85.2 Surface dry time / h 5~6 2~3 Working time / h 18~20 10~12 Gel time / s 5 19 Coating adhesion / MPa 7 21 Tensile strength / MPa 12.5 25.1 Elongation at break / % 250 429 100% modulus stress / MPa 3.3 1.8 300% modulus stress / MPa 6.5 3.1

[0071] From the test results in Table 1, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Hard work time | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com