Water-soluble nanometer organic carbon fertilizer and preparation method thereof

A nano-organic, water-soluble technology, applied in the direction of organic fertilizers, sewage/sludge fertilizers, fertilization devices, etc., can solve the problems of large land occupation, high price, and secondary pollution of organic waste, and achieve comprehensive and balanced fertilizer efficiency and low cost. The effect of low cost and less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

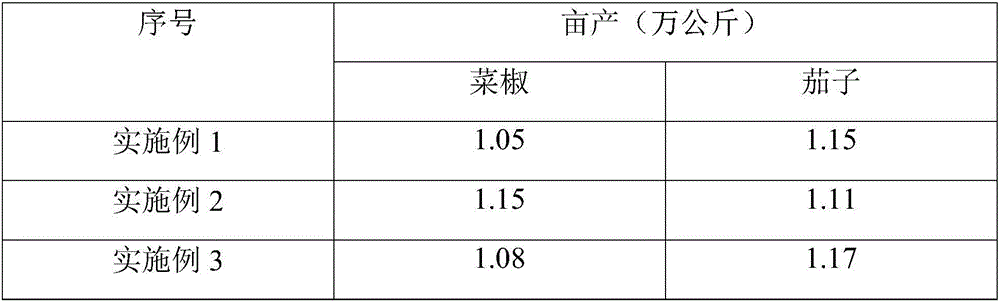

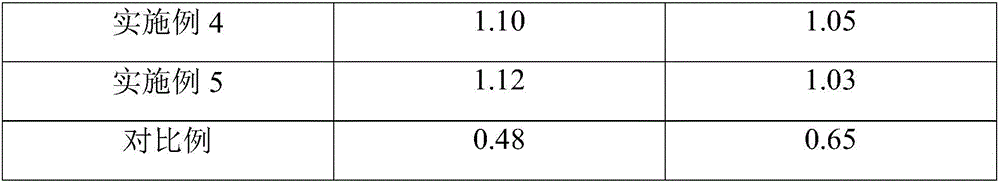

Examples

Embodiment 1

[0050] Sorting waste metals, waste plastics, waste glass, waste batteries, ceramic stones, etc. in organic waste, and spraying Bacillus subtilis, Bacillus jelly, yeast, The biodynamic modulator composed of photosynthetic bacteria, cellulase, glucanase and xylanase performs biological enzyme deodorization, and then pulverizes it into particles below 3 mm by a wet material pulverizer. After crushing, add water according to the dry-wet ratio of 1:1, and then grind it into a slurry below 5 microns through a colloid mill. 1% by weight of potassium hydroxide is added to the organic waste slurry after adding water and refined, and it is chemically cracked and homogeneously emulsified in a reaction tank through a homogeneous emulsifier. Then carry out supercritical extraction, so that the proportion of carbon-containing particles with a particle size of less than 1000 nanometers in the solution is greater than 95%. The pressure of supercritical extraction is 25-80MPa, the power is 5-2...

Embodiment 2

[0052] Sorting waste metals, waste plastics, waste glass, waste batteries, ceramic stones, etc. in organic waste, and then spraying Bacillus subtilis, Bacillus jelly, yeast, photosynthetic bacteria, cellulase, The biodynamic modulator composed of glucanase and xylanase performs biological enzymatic deodorization. After deodorization, it is crushed into particles below 5 mm by a wet material grinder. After crushing, add water according to the dry-wet ratio of 1:2, and then grind it into a slurry below 10 microns through a colloid mill or a cone mill. Add 2% by weight of ammonium hydroxide and 1% by weight of potassium persulfate to the organic waste slurry after adding water and refining, and carry out chemical cracking and homogeneous emulsification in a reaction tank through a homogeneous emulsifier. Then carry out ultra-high pressure extraction, so that the proportion of carbon-containing particles with a particle diameter of less than 1000 nanometers in the solution is gre...

Embodiment 3

[0054] Sorting waste metals, waste plastics, waste glass, waste batteries, ceramic stones, etc. in organic waste, and then spraying Bacillus subtilis, Bacillus jelly, yeast, photosynthetic bacteria, cellulase, The biodynamic modulator composed of glucanase and xylanase performs biological enzymatic deodorization. After deodorization, it is crushed into particles below 5 mm by a wet material grinder. After crushing, add water according to the dry-wet ratio of 1:1, and then grind it into a slurry below 10 microns through a colloid mill or a cone mill. Add 2% by weight of potassium hydroxide and 1% by weight of ammonium persulfate to the organic waste slurry after adding water and refining, and carry out chemical cracking and homogeneous emulsification in a reaction tank through a homogeneous emulsifier. Add large, medium and trace elements such as nitrogen, phosphorus, potassium, silicon, calcium, and magnesium to perform homogeneous emulsification again. After homogeneous emu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com