Method for preparing nanometer silicon based on introduction of metal into metallothermic reduction

A metal heat, nano-silicon dioxide technology, applied in non-metallic elements, chemical instruments and methods, silicon compounds, etc., can solve the problems of poor uniformity and dispersion of nanostructures, affecting performance, etc., and achieve uniform appearance and morphology. Improved performance, uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

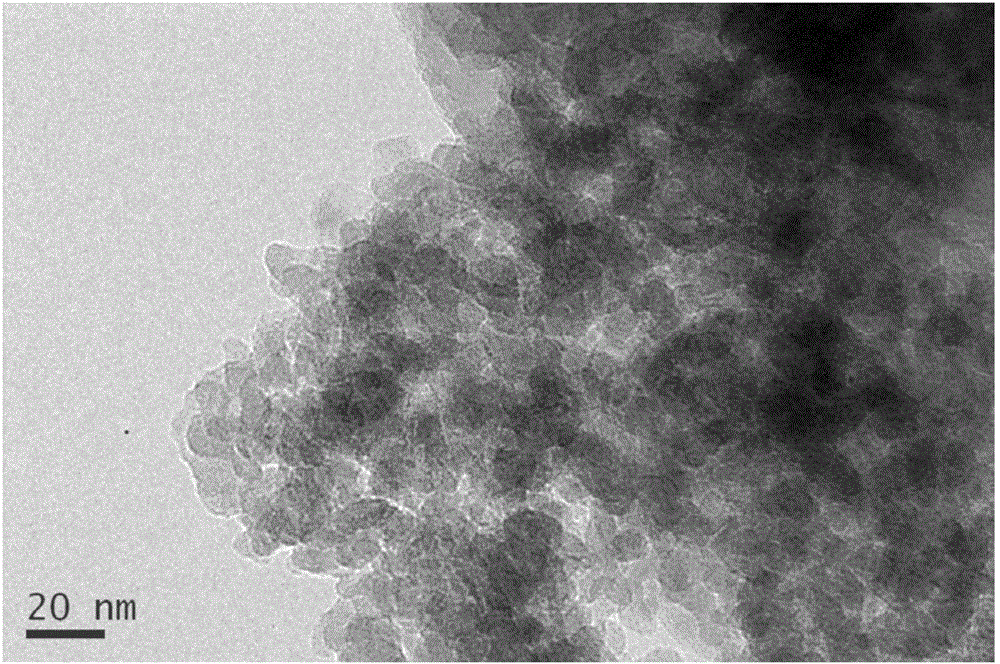

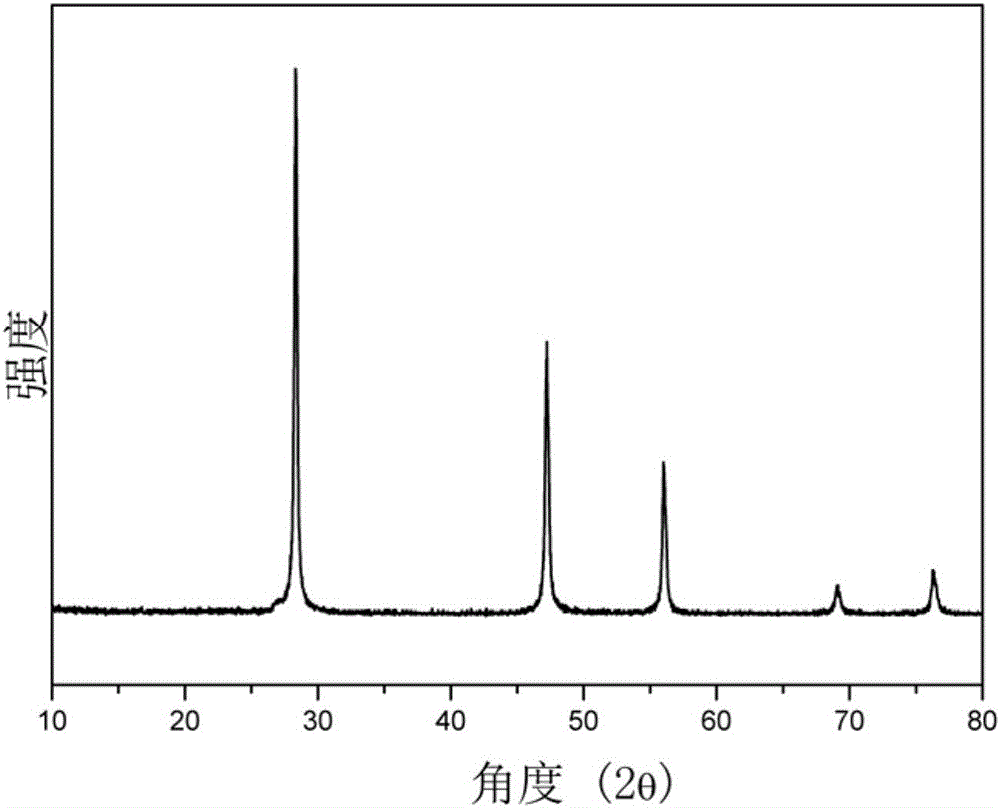

[0058] (1) Ethanol is used as a dispersant, and ethyl orthosilicate and zinc nitrate are mixed according to the ratio of zinc:silicon molar ratio of 1:4 to obtain a mixed solution 1, and ammonia water and water having a volume three times that of the mixed solution 1 are mixed. Add the mixed solution with ethanol (the volume ratio of 25% ammonia water, ethanol and water is 9:16:25) slowly into this mixed solution 1, stir at 500r / min at room temperature for 5h, filter and wash with water until neutral, and place in an oven at 80°C After drying, a silicon dioxide / zinc oxide composite precursor is obtained.

[0059] (2) Take 1g of silicon dioxide / zinc oxide composite precursor, mix it with 10g of sodium chloride, add 0.9g of metal magnesium powder, put it in a sealed tube furnace, and raise the temperature at 5°C / min to Insulate at 700°C for 10h, cool the product and treat it in 1mol / L hydrochloric acid for 6h, filter the filter residue and then treat it in 5wt% hydrofluoric acid...

Embodiment 2

[0062] (1) Methanol is used as a dispersant, and methyl orthosilicate and zinc nitrate are mixed according to the ratio of zinc:silicon molar ratio of 1:4 to obtain a mixed solution 1, and ammonia water and water having a volume three times that of the mixed solution 1 are mixed. Add the mixed solution with methanol (the volume ratio of 25% ammonia, ethanol and water is 9:16:25) slowly into this mixed solution 1, stir at room temperature at 500r / min for 5h, filter and wash with water until neutral, and place in an oven at 80°C After drying, a silicon dioxide / zinc oxide composite precursor is obtained.

[0063] (2) Take the above 1g silicon dioxide / zinc oxide composite precursor, mix it with 5g sodium chloride and 5g potassium chloride, then add 0.8g metal magnesium powder, place it in a sealed tube furnace, and heat it under an argon atmosphere 2°C / min to 650°C for 10h, after cooling, the product was treated in 2mol / L hydrochloric acid for 6h, and the filtered residue was trea...

Embodiment 3

[0066] (1) Ethanol is used as a dispersant, and ethyl orthosilicate and zinc nitrate are mixed according to the ratio of zinc:silicon molar ratio of 1:8 to obtain mixed solution 1. Add the mixed solution with ethanol (the volume ratio of 28% ammonia water, ethanol and water is 9:16:25) slowly into this mixed solution 1, stir at 500r / min at room temperature for 5h, filter and wash with water until neutral, and place in an oven at 80°C After drying, a silicon dioxide / zinc oxide composite precursor is obtained.

[0067] (2) Take the above 1g silicon dioxide / zinc oxide composite precursor, mix it with 5g sodium chloride and 5g potassium chloride, then add 0.8g metal magnesium powder, place it in a sealed tube furnace, and heat it under an argon atmosphere 2°C / min to 650°C for 10h, after cooling, the product was treated in 2mol / L hydrochloric acid for 6h, and the filtered residue was treated in 10wt% hydrofluoric acid for 0.5h, filtered and washed until neutral, and dried at 80°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com