Method for preparing polyimide using water as dispersion medium and method for recovering water

A technology of polyimide and polyimide membrane, which is applied in the field of recycling water used as a dispersion medium, can solve problems such as environmental pollution, increase in preparation cost, and residual solvents, and achieve reduction of environmental pollution, reduction of preparation cost, and reaction The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] More specifically, the present invention relates to a method for preparing polyimide. The method for preparing the above-mentioned polyimide includes: step a), dispersing the dianhydride compound and the diamine compound in water; and step b), dissolving the above-mentioned dispersion After placing in a pressure vessel and sealing it, the dianhydride compound and the diamine compound are reacted at a temperature of 5° C. to 400° C. under pressure.

[0038] The present invention relates to a preparation method of polyimide, the preparation method of the above polyimide also includes: step a), dispersing the dianhydride compound and the diamine compound in water; step b), putting the above dispersion liquid into a pressure vessel And after sealing, the dianhydride compound and the diamine compound are reacted at a temperature of 5° C. to 400° C. and under pressure; and step c), after step b) is completed, by discharging from the pressure vessel in step b ) to cool and con...

Embodiment 1-1

[0074] Example 1-1: Preparation of wholly aromatic polyimide

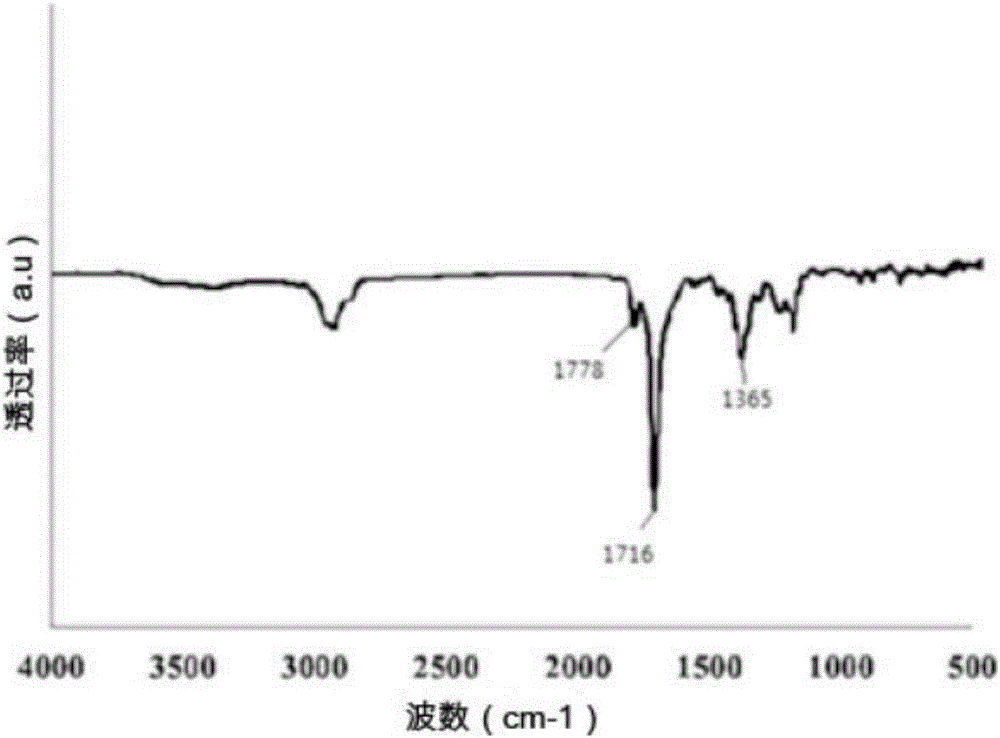

[0075] 22.6 g of pyromellitic dianhydride and 21.13 g of 4,4'-diaminodiphenyl ether were dispersed in 200 mL of distilled water. After transferring the above reaction solution to a 500mL pressure vessel with a stirrer, a nitrogen injection device and a temperature regulator attached, the air in the pressure vessel was replaced with nitrogen gas, and the temperature was adjusted to 135°C, and then under a pressure of 60bar, The polyimide was synthesized by stirring for 3 hours. After the above reaction was completed, water vapor was discharged from the pressure vessel and passed through a transfer pipe and a cooler in order to cool and condense the water vapor, thereby recovering about 180 mL of distilled water. The recovered distilled water was subjected to nuclear magnetic resonance (NMR), and it was finally confirmed that no impurities were present. In the infrared absorption spectrum of the synthesized polymer...

Embodiment 1-2

[0076] Embodiment 1-2. Preparation of fully aromatic polyimide

[0077] Disperse 11.106 g of 4,4'-(hexafluoroisopropylidene)bisaniline and 8.005 g of 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl in 200 mL of distilled water middle. After transferring the above reaction solution to a 500mL pressure vessel with a stirrer, a nitrogen injection device and a temperature regulator attached, the air in the pressure vessel was replaced with nitrogen gas, and the temperature was adjusted to 135°C, and then under a pressure of 60bar, The polyimide was synthesized by stirring for 3 hours. After the above reaction was completed, water vapor was discharged from the pressure vessel and passed through a transfer pipe and a cooler in order to cool and condense the water vapor, thereby recovering about 180 mL of distilled water. NMR was performed on the recovered distilled water, and it was finally confirmed that no impurities were present. In the infrared absorption spectrum of the synth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com