Environment-friendly emulsion-like textile size composition and preparation method and application thereof

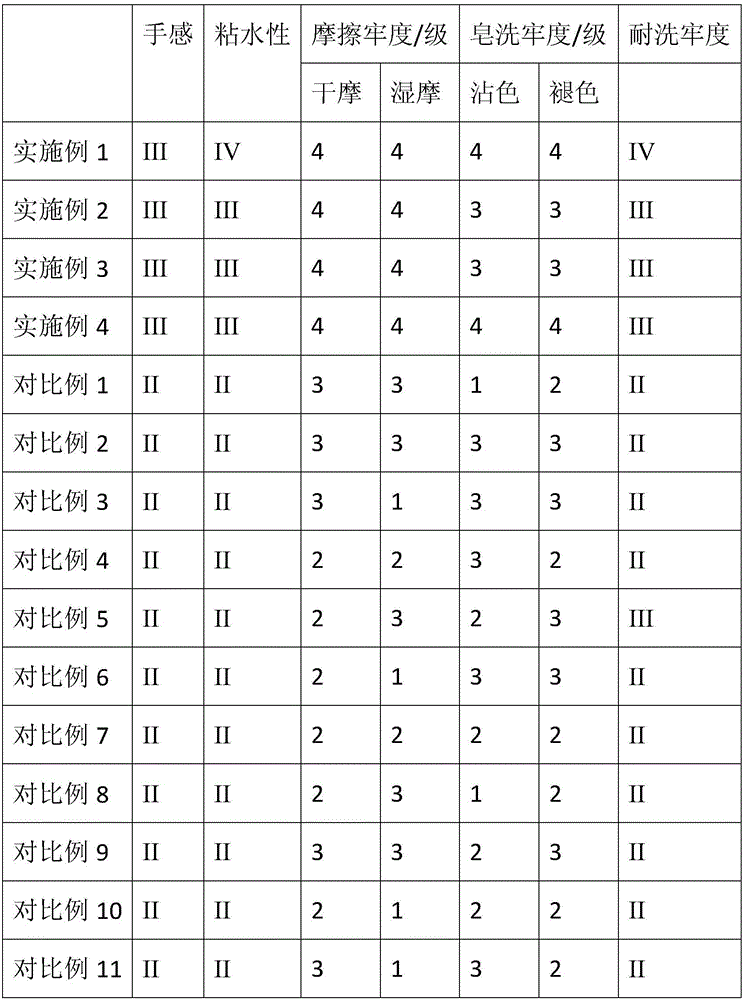

A technology of textile size and composition, which is applied in the field of environment-friendly emulsion textile size composition and its preparation, which can solve the problems of low washing fastness, hard hand feeling of fabrics, high fabric hardness, etc., and achieve high washing fastness , The fabric feels soft and has excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Weigh 8.884g of tetradecyl alcohol and 1.116g of cetyl alcohol and put them in a container, dissolve them at 80°C, then add 0.2g of disperse cationic pink, 0.6g of crystal violet lactone and 3.0g of bisphenol A and seal them Well, stir in a water bath at 80°C for 60 minutes to make a core material solution;

[0044] (2) Take 2.00g of melamine, 3.86g of formaldehyde solution and 22.5ml of distilled water, mix and stir evenly at a temperature of 70°C, adjust the pH value of the mixture to 8.5-9 with triethanolamine, and then react for 30 minutes until it is colorless and transparent shape, that is, to make a prepolymer, take it out and store it at 50°C for later use;

[0045] (3) Take 1.38g styrene-maleic anhydride copolymer and 25ml distilled water in a three-necked flask, and add 0.2gNaOH, mix thoroughly, then adjust the pH value of the solution to 4-5 with 10% citric acid, and place the solution at 50 Stirring and reacting at a temperature of ℃ for 1 h; then adding ...

Embodiment 2

[0051] (1) Weigh 7.284g of tetradecyl alcohol and 2.716g of cetyl alcohol and put them in a container, dissolve them at 80°C, then add 0.2g of disperse cationic pink, 0.6g of crystal violet lactone and 3.0g of bisphenol A and seal them Well, stir in a water bath at 80°C for 60 minutes to make a core material solution;

[0052] (2) Take 2.00g of melamine, 3.86g of formaldehyde solution and 22.5ml of distilled water, mix and stir evenly at a temperature of 70°C, adjust the pH value of the mixture to 8.5-9 with triethanolamine, and then react for 30 minutes until it is colorless and transparent shape, that is, to make a prepolymer, take it out and store it at 50°C for later use;

[0053] (3) Take 1.38g styrene-maleic anhydride copolymer and 25ml distilled water in a three-necked flask, and add 0.2gNaOH, mix thoroughly, then adjust the pH value of the solution to 4-5 with 10% citric acid, and place the solution at 50 Stirring and reacting at a temperature of ℃ for 1 h; then addin...

Embodiment 3

[0059] (1) Weigh 8.012g of tetradecyl alcohol and 1.888g of cetyl alcohol and put them in a container, dissolve them at 78°C, then add 0.1g of disperse cationic pink, 0.7g of crystal violet lactone and 3.0g of bisphenol A and seal them Well, stir in a water bath at 80°C for 60 minutes to make a core material solution;

[0060] (2) Take 1.50g of melamine, 3.62g of formaldehyde solution and 22.5ml of distilled water, mix and stir evenly at a temperature of 70°C, adjust the pH value of the mixture to 8.5-9 with triethanolamine, and then react for 30 minutes until it is colorless and transparent shape, that is, to make a prepolymer, take it out and store it at 50°C for later use;

[0061] (3) Take 1.38g styrene-maleic anhydride copolymer and 25ml distilled water in a three-necked flask, and add 0.2gNaOH, mix thoroughly, then adjust the pH value of the solution to 4-5 with 10% citric acid, and place the solution at 50 Stirring and reacting at a temperature of ℃ for 1 h; then addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com