Imitated activated pigment printing adhesive copolymer and preparation method thereof

A pigment printing and adhesive technology, which is applied in dyeing, textiles and papermaking, etc., can solve the problems affecting product stability and use effect, hard hand feeling, hydrolysis, etc., and achieve excellent rubbing fastness, hand feeling, and stability Good resistance, not easy to hydrolyze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

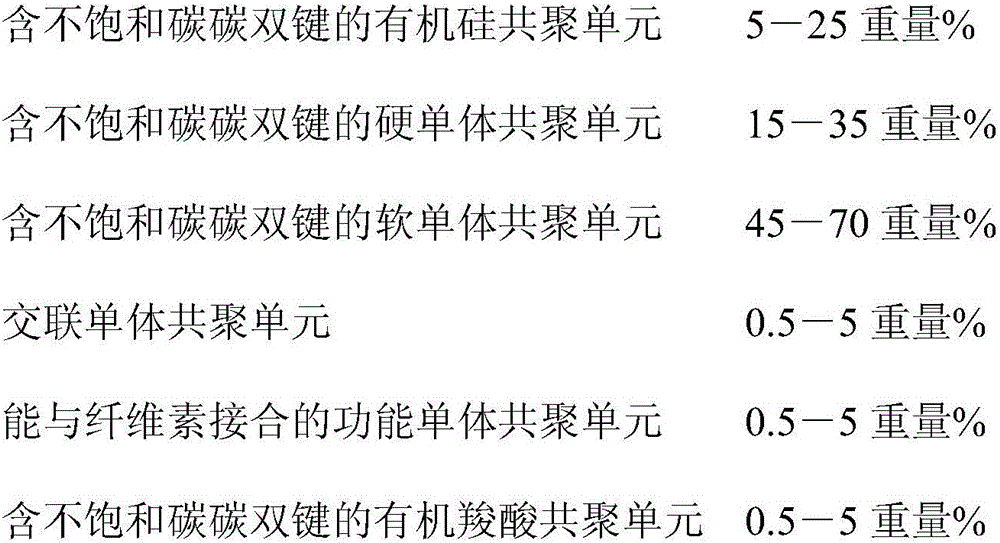

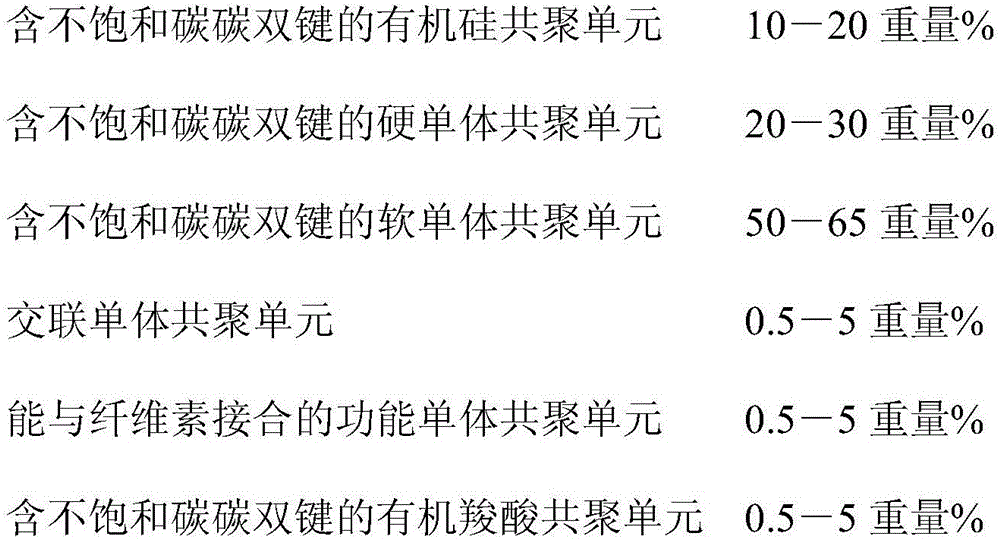

Method used

Image

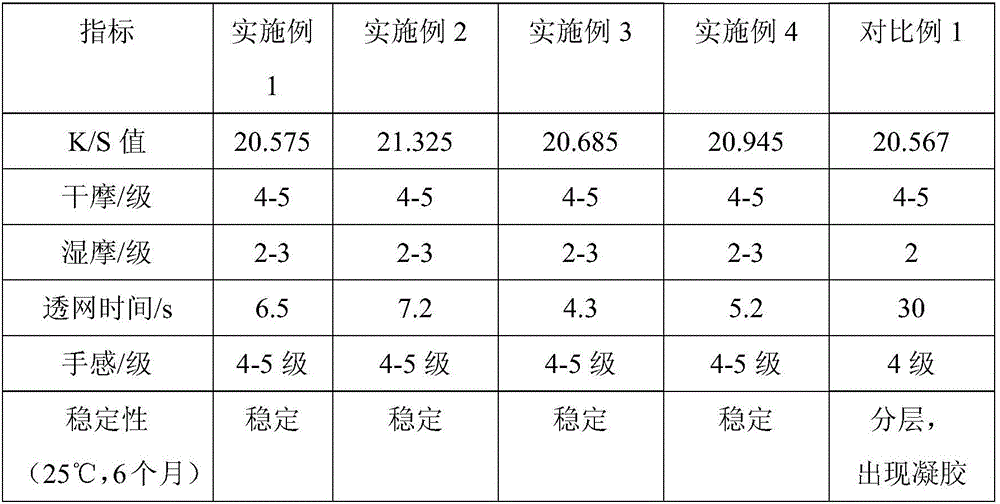

Examples

preparation example Construction

[0025] In a more preferred embodiment, the preparation method of imitation reactive pigment printing binder copolymer of the present invention comprises following preferred steps:

[0026] 1) Combine organosilicon containing unsaturated carbon-carbon double bonds, soft monomers containing unsaturated carbon-carbon double bonds, hard monomers containing unsaturated carbon-carbon double bonds, functional monomers capable of bonding with cellulose, and Stir the organic carboxylic acid with saturated carbon-carbon double bond evenly at room temperature, add the emulsifier with a weight fraction of 50-70% (to the weight of the whole emulsifier), and the deionized water with a weight fraction of 50% (to the weight of the whole deionized water) to mix , and heated to 50-60°C, emulsified for 30 minutes to obtain pre-emulsion A;

[0027] 2) the cross-linking monomer containing three or four-C=C-double bond structure, the weight fraction is 10% (to all deionized water weight) deionized ...

Embodiment 1

[0061] 1) 1 part by weight of tetramethyldivinyldisiloxane, 2 parts by weight of vinyl-terminated polydimethylsiloxane (viscosity of 100000mPa·s), 1 part by weight of methyl-vinylsiloxane, 5 parts by weight of n-butyl acrylate, 5 parts by weight of ethyl acrylate, 15 parts by weight of isobutyl acrylate, 5 parts by weight of methyl methacrylate, 2 parts by weight of vinyl acetate, 2 parts by weight of styrene, 0.5 parts by weight of methyl Mix acrylic acid evenly, add 0.9 parts by weight of sodium lauryl sulfate, 1.8 parts by weight of isomeric tridecyl alcohol polyoxyethylene ether (EO number is 8), 27 parts by weight of deionized water, stir, and heat up to 50-60 °C , emulsified for 30 minutes to obtain 68.2 parts by weight of pre-emulsion A;

[0062] 2) 0.5 parts by weight of ditrimethylolpropane tetraacrylate, 5.4 parts by weight of deionized water, 0.3 parts by weight of sodium lauryl sulfate, 0.6 parts by weight of isomeric tridecyl alcohol polyoxyethylene ether (EO numb...

Embodiment 2

[0067] 1) 2 parts by weight of vinyl tris(trimethylsiloxane) silane, 3 parts by weight of vinyl terminated polydimethylsiloxane (viscosity of 100000mPa·s), 13 parts by weight of isooctyl acrylate, 5 parts by weight of ethyl acrylate, 5 parts by weight of lauryl acrylate, 5 parts by weight of methyl methacrylate, 2 parts by weight of vinyl acetate, 2 parts by weight of acrylonitrile, 0.5 parts by weight of styrene benzene sulfonic acid, mixed evenly, adding 1.2 parts by weight Parts of sodium secondary alkyl sulfonate, 2.4 parts by weight of fatty alcohol polyoxyethylene ether (AEO-9), 26.5 parts by weight of deionized water, stirred, heated to 50-60°C, and emulsified for 30 minutes to obtain 67.6 parts by weight of pre-emulsion A ;

[0068] 2) Mix 0.5 parts by weight of pentaerythritol tetraacrylate, 5.3 parts by weight of deionized water, 0.4 parts by weight of sodium secondary alkyl sulfonate, and 0.8 parts by weight of fatty alcohol polyoxyethylene ether (AEO-9), stir and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com