Antibacterial polycarbonate foamed plastics and preparation method thereof

A technology of polycarbonate and foamed plastics, which is applied in the preparation of the antibacterial polycarbonate foamed plastics, and in the field of antibacterial polycarbonate foamed plastics, can solve problems such as unfavorable health and susceptibility to bacterial contamination, and achieve production saving The effect of time, pore size and distribution, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

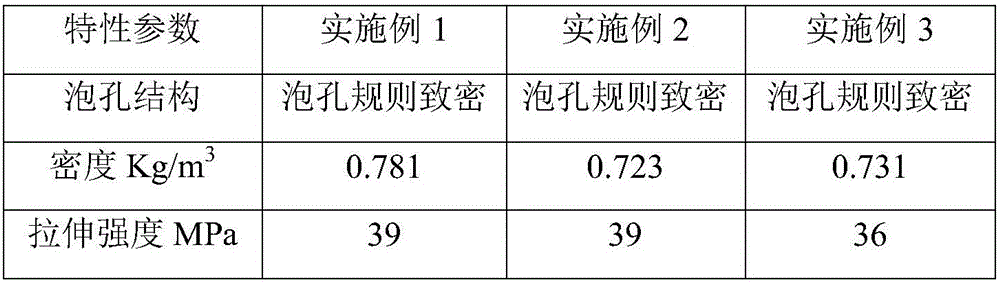

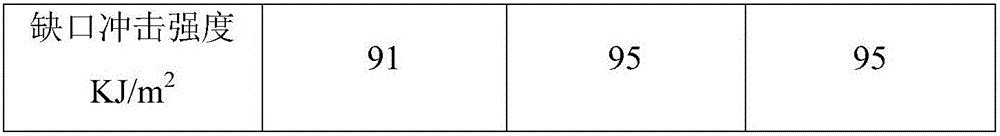

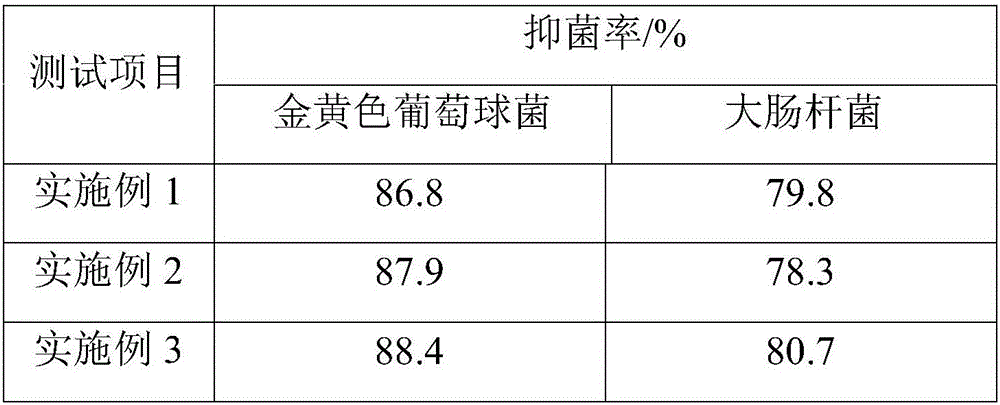

Embodiment 1

[0034] An antibacterial polycarbonate foamed plastic, the raw material for making the antibacterial polycarbonate foamed plastic includes the following components in parts by weight: 100 parts of polycarbonate, 10 parts of glass fiber cloth, 4 parts of mulberry fiber, aromatic 8 parts of rayon pulp, 6 parts of expanded perlite, 2 parts of calcium carbonate, 2 parts of azodicarbonamide, 1 part of triethanolamine, 1 part of polyether modified silicone oil, 1 part of maleic anhydride, 10 parts of pure acrylic emulsion, 1 part of laurozone, 6 parts of tea dregs, 10 parts of dried loofah vine, 4 parts of lanthanum-loaded zinc oxide, 4 parts of cerium-loaded titanium dioxide, and 0.6 part of sodium lignosulfonate.

[0035] The preparation method of described antibacterial polycarbonate foam plastic comprises the following steps:

[0036](1) Weigh the glass fiber cloth ear material, clean it until there is no mud, dirt, etc., dry it until there is no moisture, and then send the dried...

Embodiment 2

[0045] A kind of antibacterial polycarbonate foamed plastics, the raw material that makes this antibacterial polycarbonate foamed plastics comprises each composition of following parts by weight: polycarbonate 120 parts, glass fiber cloth 20 parts, mulberry fiber 6 parts, aromatic 10 parts of rayon pulp, 10 parts of expanded perlite, 3 parts of calcium carbonate, 4 parts of azodicarbonamide, 2 parts of triethanolamine, 2 parts of polyether modified silicone oil, 2 parts of maleic anhydride, 20 parts of pure acrylic emulsion, 3 parts of laurozone, 10 parts of tea dregs, 20 parts of dried loofah vine, 8 parts of zinc oxide loaded with lanthanum, 6 parts of titanium dioxide loaded with cerium, and 0.8 parts of sodium lignosulfonate.

[0046] The preparation method of described antibacterial polycarbonate foam plastic comprises the following steps:

[0047] (1) Weigh the glass fiber cloth ear material, clean it until there is no mud, dirt, etc., dry it until there is no moisture, ...

Embodiment 3

[0056] A kind of antibacterial polycarbonate foamed plastics, the raw material that makes this antibacterial polycarbonate foamed plastics comprises each composition of following parts by weight: polycarbonate 110 parts, glass fiber cloth 15 parts, mulberry fiber 5 parts, aromatic 9 parts of rayon pulp, 8 parts of expanded perlite, 2.5 parts of calcium carbonate, 3 parts of azodicarbonamide, 1.5 parts of triethanolamine, 1.5 parts of polyether modified silicone oil, 1.5 parts of maleic anhydride, 15 parts of pure acrylic emulsion, 2 parts of laurozone, 8 parts of tea dregs, 15 parts of dried loofah vine, 6 parts of zinc oxide loaded with lanthanum, 5 parts of titanium dioxide loaded with cerium, and 0.7 parts of sodium lignosulfonate.

[0057] The preparation method of described antibacterial polycarbonate foam plastic comprises the following steps:

[0058] (1) Weigh the glass fiber cloth ear material, clean it until there is no mud, dirt, etc., dry it until there is no moist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com