A kind of preparation method of cross-linked aqueous acrylic acid emulsion

A water-based acrylic emulsion technology, which is applied in the field of preparation of cross-linked water-based acrylic emulsion, can solve problems such as limited application, and achieve the effect of solving yellowing and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

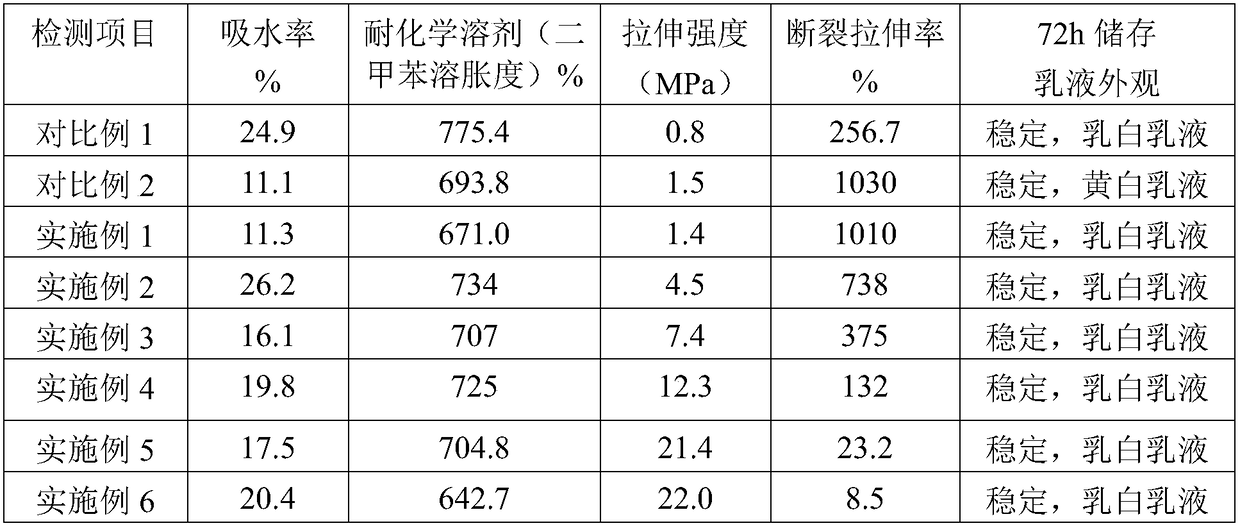

Examples

Embodiment 1

[0023] First, mix 100 parts of glutaraldehyde aqueous solution and 70 parts of methanol, adjust the pH value to 1-2 with dilute hydrochloric acid, reflux at 60°C for 1 hour, cool to room temperature, add 70 parts of 30% formaldehyde aqueous solution and 1 part of Na 2 CO 3 , heated up again to 90° C. for reflux for 2 hours, cooled down and discharged. Unreacted methanol and formaldehyde were distilled off under reduced pressure, and water was added to obtain a modified glutaraldehyde crosslinking agent with a concentration of 20%.

[0024] Add 140 parts of water, 1 part of sodium dodecylbenzenesulfonate, and 2 parts of OP-10 emulsifier into the pre-emulsification tank, start stirring, raise the temperature to 40-50°C, and evenly add 9 / 10 of acrylate mono Liquid mixture (106 parts of butyl acrylate, 86 parts of methyl methacrylate, 8 parts of methacrylic acid and 3.55 parts of acrylamide), dripping in 0.5~1h. Add 80 parts of water, 0.5 parts of sodium dodecylbenzene sulfonate...

Embodiment 2

[0026] First, mix 100 parts of glyoxal aqueous solution and 70 parts of methanol, adjust the pH value to 1-2 with dilute hydrochloric acid, reflux at 60°C for 1 hour, cool down to room temperature, add 70 parts of 30% formaldehyde aqueous solution and 1 part of Na 2 CO 3 , heated up again to 90° C. for reflux for 2 hours, cooled down and discharged. Unreacted methanol and formaldehyde were distilled off under reduced pressure, and water was added to obtain a modified glyoxal crosslinking agent with a concentration of 20%.

[0027] Add 140 parts of water, 0.75 parts of sodium lauryl sulfate, and 0.75 parts of OP-10 emulsifier into the pre-emulsification tank, start stirring, raise the temperature to 40-50°C, and evenly add 9 / 10 acrylate monomer dropwise to mix Liquid (113 parts of butyl methacrylate, 10 parts of methyl methacrylate, 10 parts of diethylene glycol diacrylate, 40 parts of styrene, 20 parts of methacrylic acid, 7 parts of acrylamide), drop in 0.5-1h . Add 80 par...

Embodiment 3

[0029] First, mix 100 parts of succinic dialdehyde aqueous solution and 70 parts of methanol, adjust the pH value to 1-2 with dilute hydrochloric acid, reflux at 60°C for 1 hour, cool to room temperature, add 70 parts of 30% formaldehyde aqueous solution and 1 part of Na 2 CO 3 , heated up again to 90° C. for reflux for 2 hours, cooled down and discharged. Unreacted methanol and formaldehyde were distilled off under reduced pressure, and water was added to obtain a modified succinaldehyde crosslinking agent with a concentration of 20%.

[0030] Add 140 parts of water, 0.6 parts of dodecyl diphenyl ether sulfonic acid disodium salt, 2.4 parts of TX-100 emulsifier into the pre-emulsification tank, start stirring, raise the temperature to 40-50°C, and evenly add 9 / 10 Acrylic monomer mixture (95 parts of butyl acrylate, 10 parts of hydroxyethyl acrylate, 10 parts of isobornyl methacrylate, 40 parts of methyl methacrylate, 30 parts of α-methylstyrene, 10 parts of acrylic acid , m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com