Compounding method for nanometer ultrathin boron carbon nitrogen sheet

A technology of boron carbon nitrogen nanometer synthesis method, which is applied in the field of synthesis of ultra-thin boron carbon nitrogen nanosheets, can solve problems such as unfavorable large-scale production, expensive experimental raw materials, and harsh experimental conditions, and is conducive to large-scale promotion , good controllability and repeatability, simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

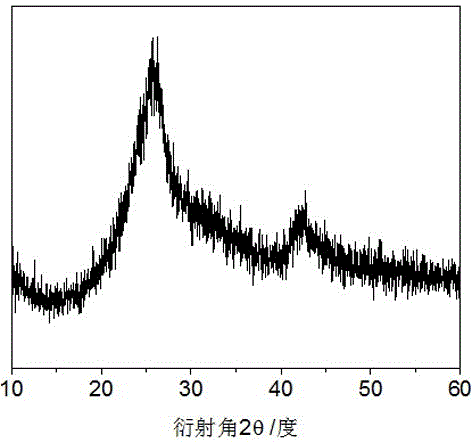

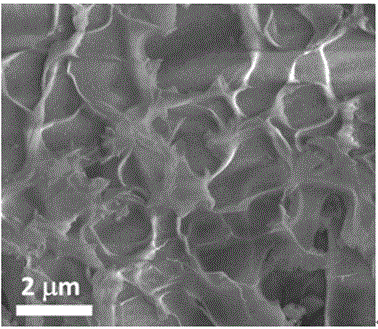

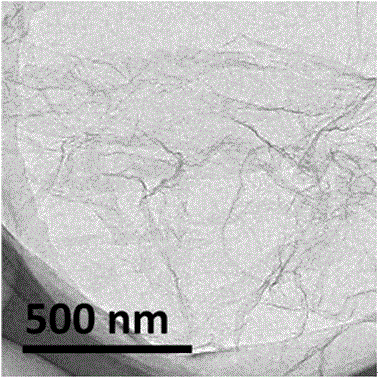

Embodiment 1

[0018] Weigh the mixed salt composed of diboron trioxide, melamine, glucose, NaCl and KCl according to the mass ratio of 1:1:10:50 (the mass ratio of NaCl and KCl is 45:55), then mix diboron trioxide, melamine and Glucose is put into a mortar, mixed salt is added and ground evenly, the obtained powder is put into a horizontal high-temperature tube furnace, and in an ammonia atmosphere, the temperature is raised to 1000°C at a rate of 10°C / min, and heat-treated for 5 hours to obtain boron Carbon Nitride Nanosheets.

Embodiment 2

[0020] Weigh the mixed salt composed of diboron trioxide, melamine, glucose, NaCl and KCl according to the mass ratio of 1:0.5:6:5 (the mass ratio of NaCl and KCl is 45:55), then mix diboron trioxide, melamine and Glucose is put into a mortar, mixed salt is added and ground evenly, the obtained powder is put into a horizontal high-temperature tube furnace, and in an ammonia atmosphere, the temperature is raised to 1250°C at a rate of 5°C / min, and heat-treated for 10 hours to obtain boron Carbon Nitride Nanosheets.

Embodiment 3

[0022] Weigh the mixed salt composed of boron trioxide, melamine, glucose, NaCl and KCl according to the mass ratio of 1:2:7:100 (the mass ratio of NaCl and KCl is 45:55), and then mix the boron trioxide, melamine and Glucose is put into a mortar, mixed salt is added and ground evenly, the obtained powder is put into a horizontal high-temperature tube furnace, and in an ammonia atmosphere, the temperature is raised to 900°C at a rate of 5°C / min, and heat-treated for 5 hours to obtain boron Carbon Nitride Nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com