Centralized filtration and oil supply system for machine tool machining

A technology of oil supply system and machine tool, which is applied in the direction of metal processing equipment, manufacturing tools, magnetic separation, etc. It can solve the problems of large investment in equipment, large overall energy consumption, affecting surface roughness and service life of precision tools, and achieves power saving. Cost and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

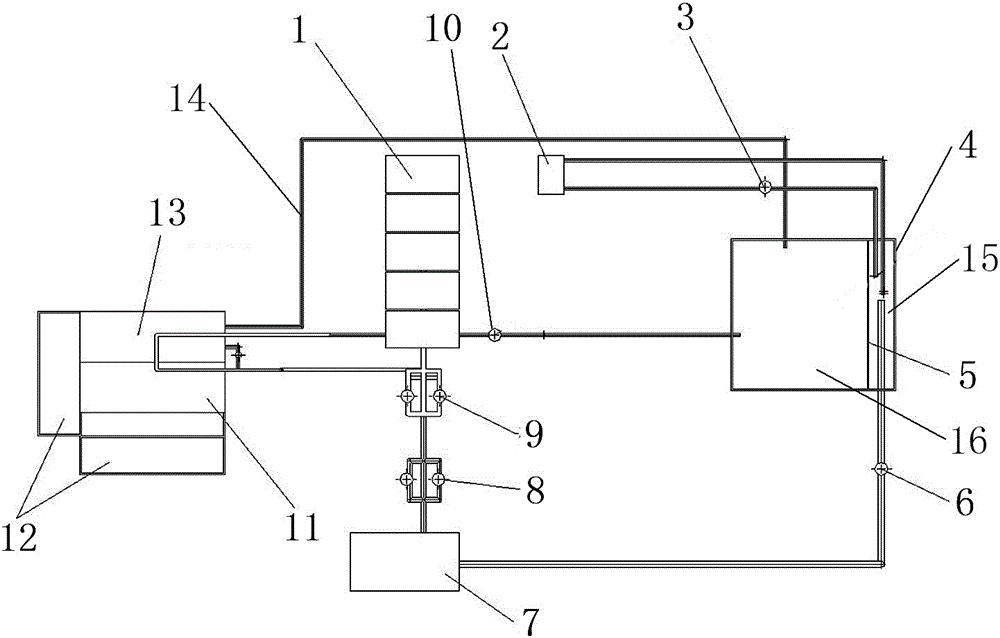

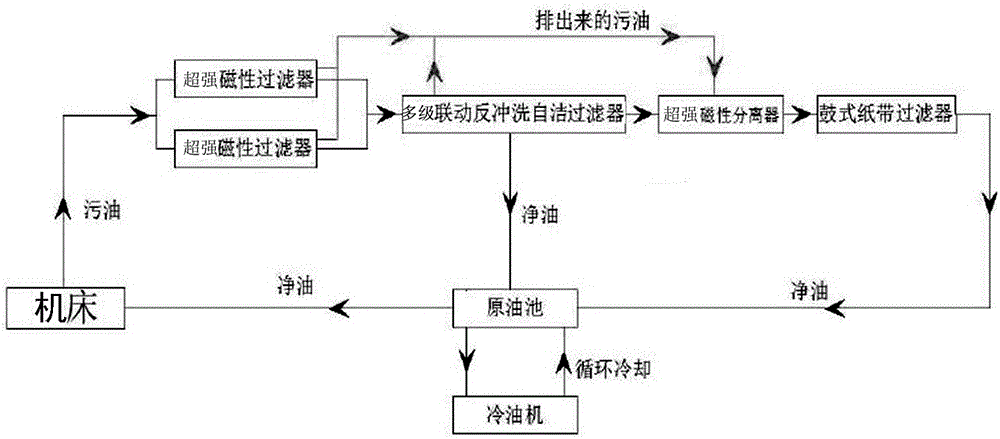

[0026] See attached figure 1 and figure 2 , a centralized filter oil supply system for machine tool processing, including a dirty oil pipeline connected to the outside of the machine tool, the dirty oil pipeline is connected with a dirty oil pump 8 and a super-strong magnetic filter 9 in sequence, and the super-strong magnetic filter 9 outputs The ends are respectively connected to a multi-stage linkage backwash self-cleaning filter 1 and a super-strong magnetic separator 13, and the output end of the multi-stage linkage backwash self-cleaning filter 1 is also connected to the super-strong magnetic separator 13, And the output end of the multi-stage linkage backwashing self-cleaning filter 1 is also connected to a crude oil pool 4, and the output end of the super-strong magnetic separator 13 is connected to the crude oil pool 4 through a drum type paper tape filter 11, the The super-strong magnetic separator 13 and the drum type paper filter 11 are also connected with a wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com