Method and device for coupling and biologically purifying VOCs under optical/thermal double-driving catalysis

A biological purification and dual-drive technology, which is applied in the field of environmental pollution purification, can solve the problems of adsorbent regeneration, difficult continuous operation of the process, and inability to realize waste gas, so as to improve energy utilization rate, strong technical applicability, and realize mineralization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 A method for optical / thermal dual-drive catalytic coupling biological purification of VOCs exhaust gas, characterized in that:

[0038] 1) Adjust the humidity of the VOCs exhaust gas to be purified, and control the humidity of the VOCs exhaust gas to be purified at 50%-80%;

[0039] 2) According to whether the VOCs exhaust gas with a specific humidity contains refractory components (such as VOCs containing benzene rings, VOCs containing chlorine atoms, etc.), selectively adjust the gear position of the three-way gas reversing valve so that the VOCs exhaust gas with a specific humidity enters the Main road system (containing difficult biodegradable components) or bypass system (excluding difficult biodegradable components), wherein said main road system communicates with low-temperature plasma-driven photo / thermal catalytic unit, and bypass system communicates with biological filler Reactor communication;

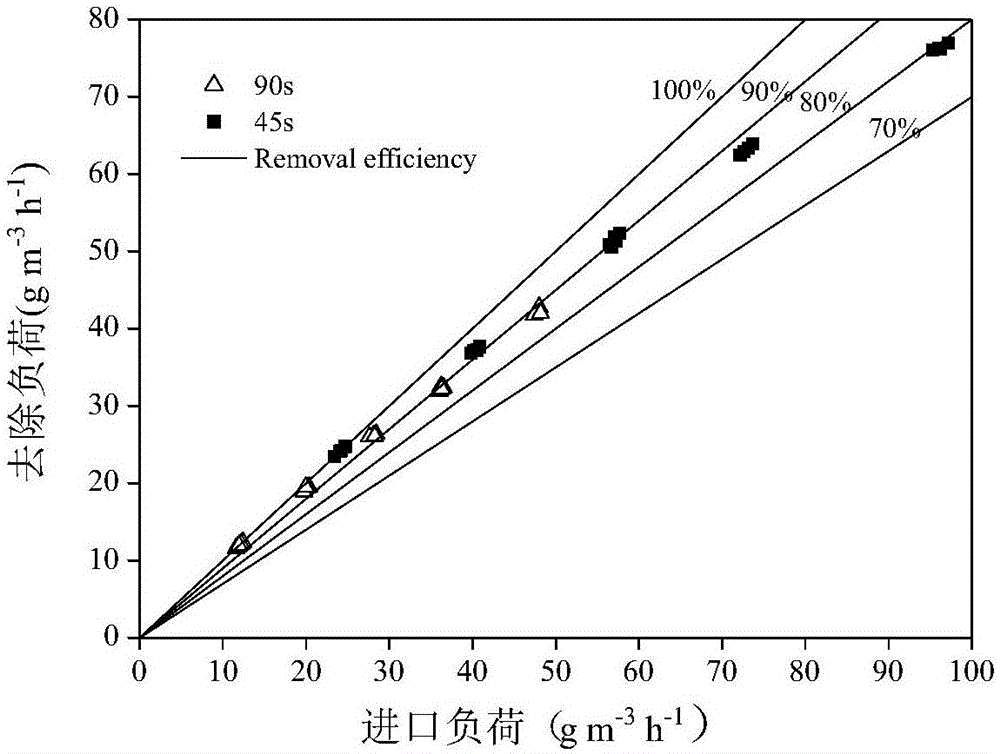

[0040] 3) For the VOCs exhaust gas with a specific...

Embodiment 2

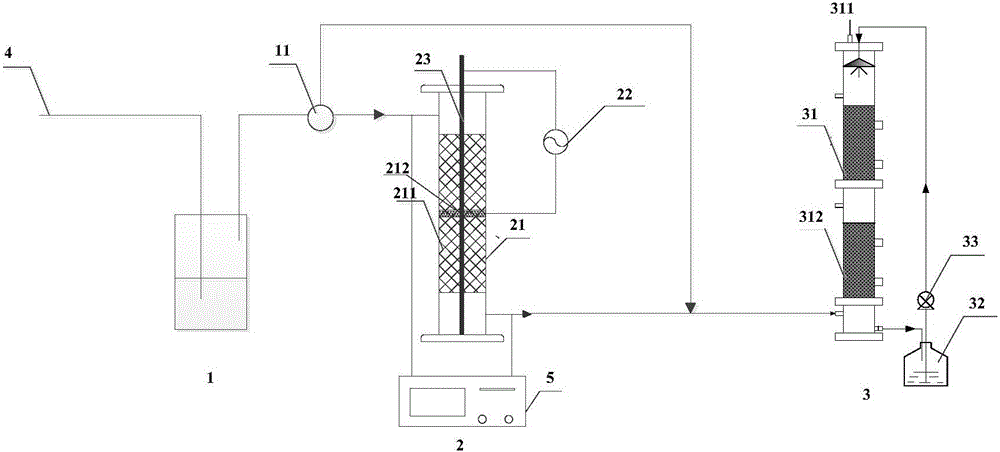

[0044] Example 2 A device constructed according to the method of photo / thermal dual-drive catalytic coupling biological purification of VOCs exhaust gas described in Example 1, including a humidity adjustment device 1, a photo / thermal dual-drive catalytic unit 2 and a biological purification unit 3, the The air inlet of the humidity adjusting device 1 is connected with the exhaust gas source 4 to be purified, the air outlet of the humidity adjusting device 1 is connected with the air inlet of the three-way gas reversing valve 11, and the The first gas outlet of the three-way gas reversing valve 11 communicates with the air inlet pipeline of the light / heat dual-drive catalytic unit 2 through the main road system, and the second gas outlet of the three-way gas reversing valve 11 , The air outlets of the light / heat dual-drive catalytic unit 2 are all connected with the air inlet pipeline of the biological purification unit 3;

[0045] The photo / thermal dual-driven catalytic unit ...

Embodiment 3

[0050] Example 3: Preparation of Light / Heat Dual Drive Catalyst

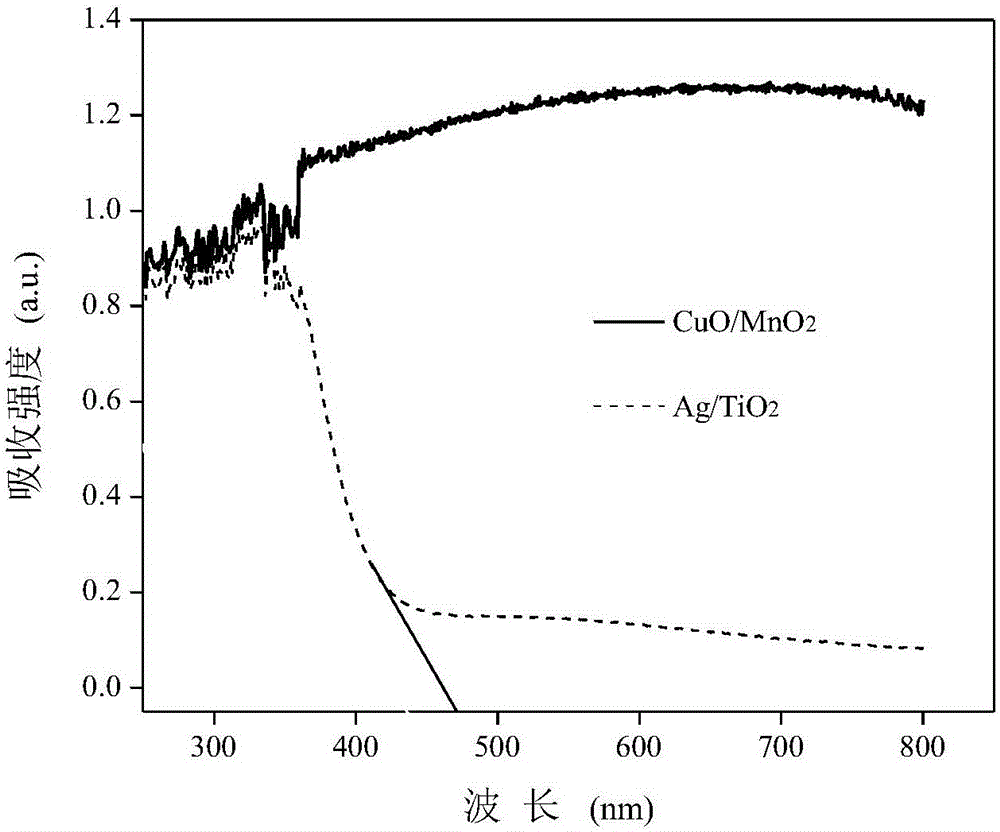

[0051] Preparation of Copper-Manganese Composite Oxide Catalyst

[0052] Take 2g of MnCO 3 placed in a muffle furnace at O 2 Calcined at 400 °C for 5 h in the atmosphere to prepare porous MnO 2 spare. Take 0.38g Cu(NO 3 ) 2 ·3H 2 O, dissolved in 2mL of deionized water, weighed 1.0gMnO 2 Add while stirring, dry at 80°C for 12h, 400°C 2 Calcined in the atmosphere for 2h, cooled and taken out to obtain 40% CuO / MnO 2 .

[0053] Preparation of Noble Metal Silver-Titanium Composite Catalyst

[0054] Weigh 0.075g of AgNO 3 Dissolve in 100mL of deionized water, and after the solid is completely dissolved, wash with glacial acetic acid (CH 3 COOH) will AgNO 3 The pH of the solution was adjusted to about 2.5, and then transferred to a three-neck flask, and 21 mL of butyl titanate (Ti(OC 4 h 9 ) 4 ) into the above solution at a rate of about 3 s / drop, and continue to stir for 3 hours after the drop is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com