A kind of ultra-low shrinkage composite resin and preparation method thereof

A composite resin and ultra-low shrinkage technology, which can be used in pharmaceutical formulations, dental preparations, compression molding cups, etc., can solve the problems of product pH increase, damage to material bioactivity and biocompatibility, etc., and achieve simple preparation process, The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides an ultra-low shrinkage composite resin and a preparation method thereof, and the specific technical scheme is as follows:

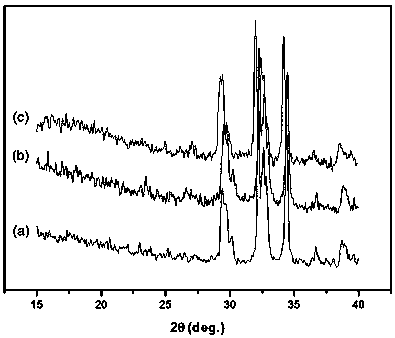

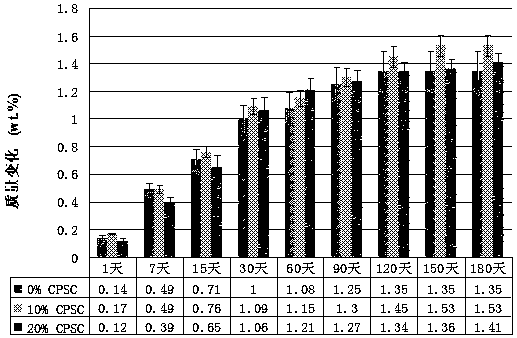

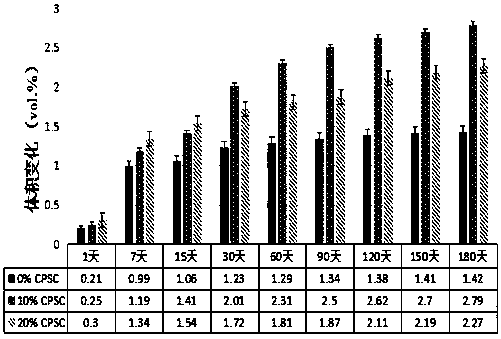

[0036] 1. Synthesis and microstructure characterization of new ultra-low shrinkage composite resin

[0037] The ultra-low shrinkage composite resin is composed of 30wt% resin matrix and 70wt% inorganic filler, wherein: the resin matrix contains 49.5wt% Bis-GMA, 49.5wt% TEGDMA, 0.5wt% CQ, 0.5 wt% of DMAEMA; the inorganic filler is barium glass powder (average diameter 0.8 μm) silanized on the surface, and silicon calcium phosphate powder (mass ratio of calcium silicate to calcium superphosphate is 9:1) is respectively mixed with 0wt%, 10wt%, 20wt% partially replace the inorganic filler of the composite resin, add to the composite resin and mix evenly. The specific ratio of materials is shown in Table 1.

[0038] Table 1 Synthesized composite resin components and ratio

[0039]

[0040] The preparation steps of the abov...

Embodiment 2

[0063] The difference between this example and Example 1 is that the ultra-low shrinkage composite resin is composed of 50wt% resin matrix and 50wt% inorganic filler, wherein: the resin monomer is UTMA, the diluent is EGDMA, the mass of the two The ratio is 70 / 30; the photoinitiator is benzil, and the organic amine activator is EDB, and the content of the two in the resin matrix is 0.3wt%; the inorganic filler is the quartz powder of surface silanization, and the Calcium silicon phosphate powder is used to replace inorganic fillers at 0wt%, 10wt%, and 20wt%.

Embodiment 3

[0065] The difference between this embodiment and Example 1 is: the resin monomer is Bis-EMA and Bis-GMA, the mass ratio of the two is 1:1, and the diluent is cyclohexamethylene glycol dimethacrylate, The mass ratio of resin monomer and diluent is 60 / 40; Described photoinitiator is trimethylbenzoyl, and organic amine activator is DMT, and the content of both in resin matrix is 0.7wt%; Described The inorganic filler is porcelain powder with a silanized surface, and the silicon calcium phosphate powder is partially replaced by 0wt%, 10wt%, and 20wt% of the inorganic filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com