Molybdenum boride ceramic system hot spray coating material, and preparation method and application of molybdenum boride ceramic system hot spray coating material

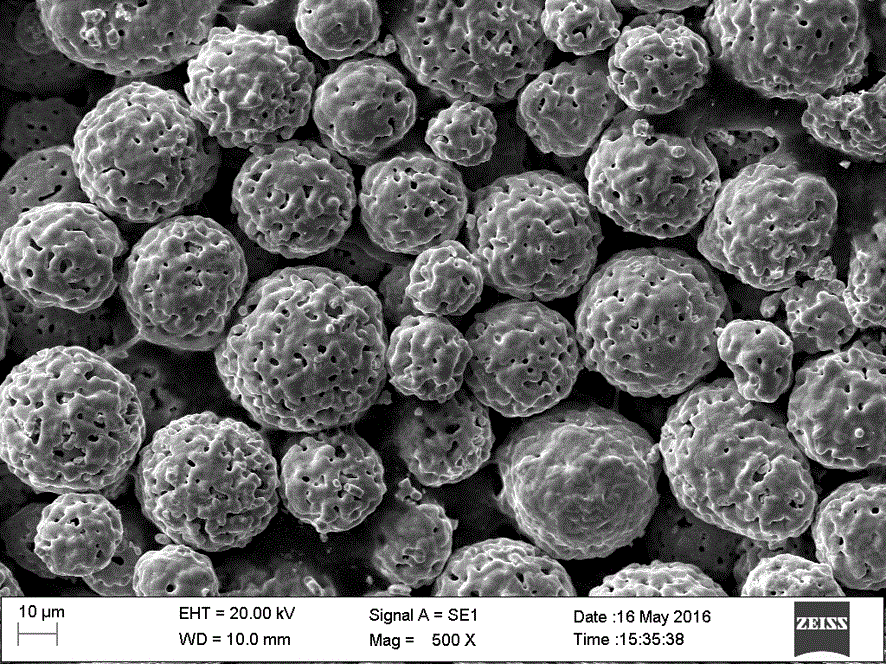

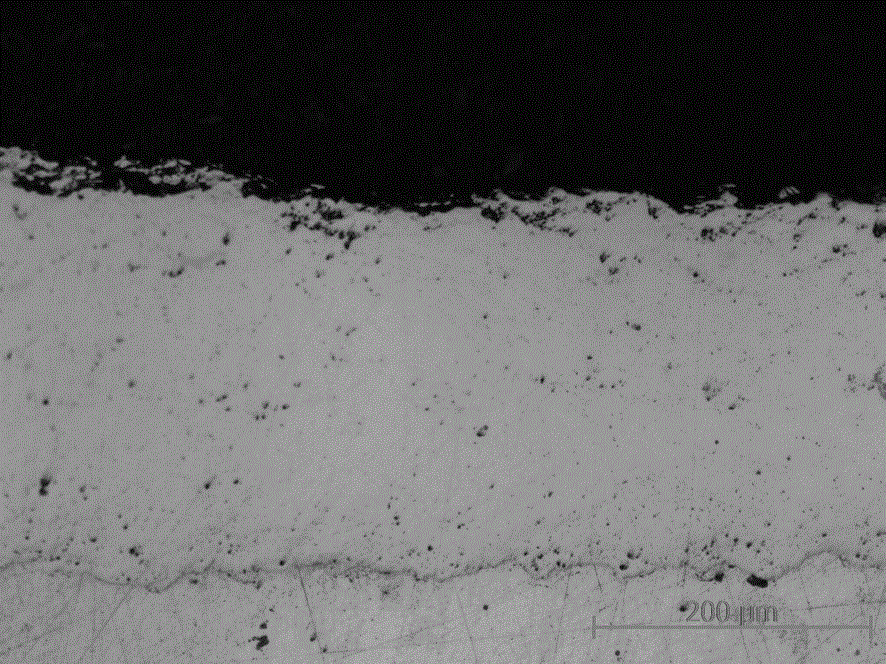

A coating material and thermal spraying technology, applied in coating, metal material coating process, fusion spraying, etc., can solve unsatisfactory coating performance, easy cracking of surface boronizing coating, and coating life No long-term problems, to achieve the effect of high hardness, good fluidity and excellent sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) According to MoB 69%, MoB 2 6%, Ni 17%, Cr 5%, WB 1.5%, WB 2 1.5% by weight proportioning ingredients, used MoB, MoB 2 and WB, WB 2The average particle size of raw materials is 4 μm, the average particle size of Ni raw materials is 3 μm, and the average particle size of Cr raw materials is 3 μm. Put the materials into a ball mill, and use pure water with a conductivity of 4 us / cm as the grinding medium according to the ball-to-material ratio of 4:1. , and add polyvinyl alcohol accounting for 16% of the total mass of raw materials to the mixed material, and perform ball milling for 24 hours; after that, spray the obtained slurry to granulate, and then sinter under vacuum conditions, the sintering vacuum degree is -98KPa, and the sintering temperature It is 1400℃, and the sintering time is 0.5h. After sintering, the obtained material is pulverized, and then the obtained powder is classified to obtain a thermal spray coating material with a particle size of 15-45 μ...

Embodiment 2

[0036] 1) According to MoB 52%, MoB 2 8%, Co19%, Cr 16%, WB 3%, WB 2 1%, W 2 B 5 1% weight percentage proportioning ingredients, MoB and MoB used 2 and WB, WB 2 , W 2 B 5 The average particle size of raw materials is 1 μm, the average particle size of Co raw materials is 0.8 μm, and the average particle size of Cr raw materials is 3 μm. Put the materials into a ball mill, and use pure water with a conductivity of 5 us / cm as the grinding according to the ball-to-material ratio of 3:1. Medium, and add polyvinyl alcohol accounting for 11% of the total mass of raw materials to the mixed material, and perform ball milling for 72 hours; after that, spray granulate the obtained slurry, and then sinter under vacuum conditions, the sintering vacuum degree is -96KPa, sintering The temperature is 1100°C, and the sintering time is 4h. After sintering, the obtained material is pulverized, and then the obtained powder is classified to obtain a thermal spray coating material with a p...

Embodiment 3

[0040] 1) According to MoB 58%, MoB 2 2%, Co 30%, Cr 5%, WB 2%, WB 2 3% by weight proportioning ingredients, MoB and MoB used 2 and WB, WB 2 The average particle size of raw materials is 5 μm, the average particle size of Co raw materials is 2 μm, and the average particle size of Cr raw materials is 2 μm. Put the materials into a ball mill, and use pure water with a conductivity of 3 us / cm as the grinding medium according to the ball-to-material ratio of 4:1. , and add polyvinyl alcohol accounting for 16% of the total mass of raw materials to the mixed material, and carry out ball milling for 72 hours; after that, spray granulate the obtained slurry, and then carry out sintering under vacuum conditions, the sintering vacuum degree is -96KPa, and the sintering temperature It is 1000℃, and the sintering time is 3h. After sintering, the obtained material is pulverized, and then the obtained powder is classified to obtain a thermal spray coating material with a particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com