Schiff base palladium anion intercalated hydrotalcite, preparation method thereof and application thereof

An anion intercalation and Schiff base technology, applied in chemical instruments and methods, catalytic reactions, organic compounds/hydrides/coordination complex catalysts, etc., to achieve good reusability, improve dispersion and utilization, atomic Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

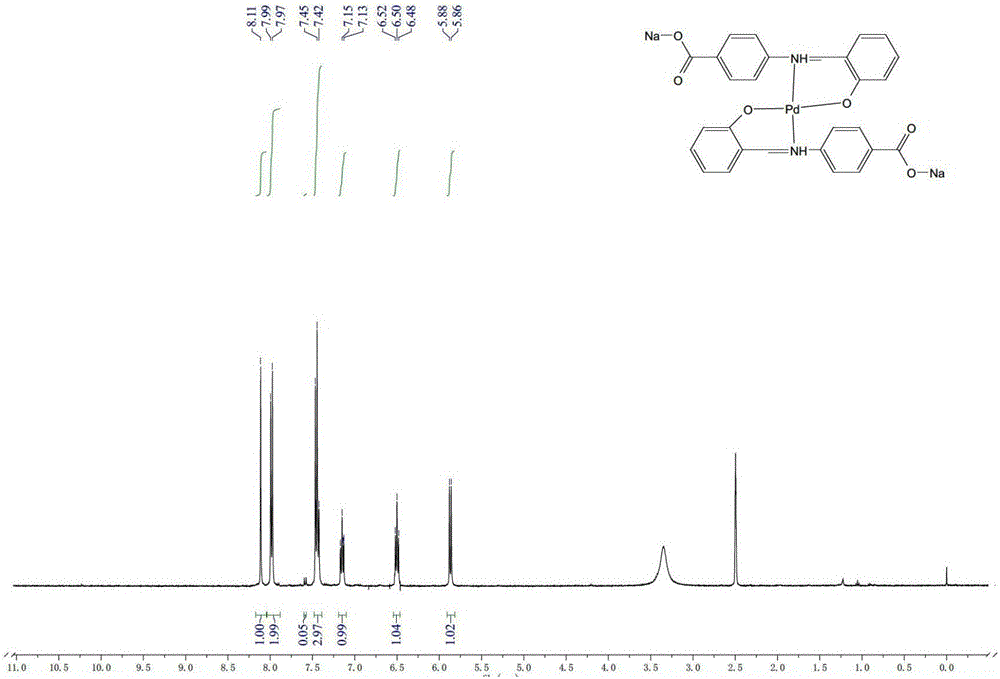

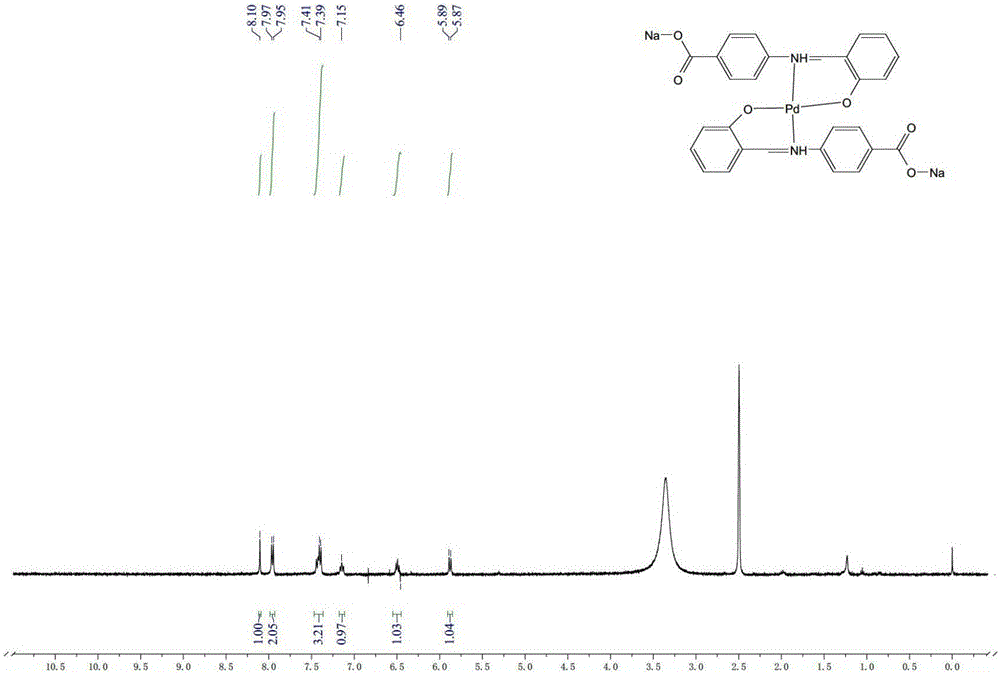

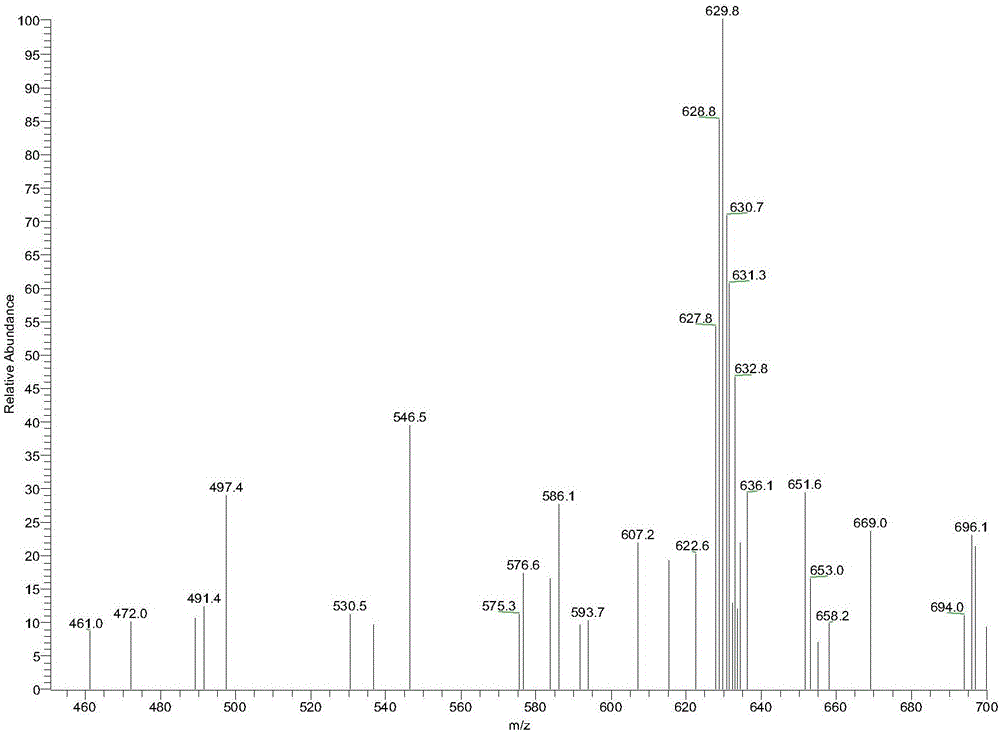

[0048] 1. Preparation of p-aminobenzoic acid salicylaldehyde Schiff base: Weigh 3.672g (0.03mol) of salicylaldehyde and 4.128g (0.03mol) of p-aminobenzoic acid, respectively dissolve them in 60mL of water. Add the salicylaldehyde solution dropwise into the three-necked flask containing the p-aminobenzoic acid solution, stir at room temperature for 45 minutes after dropping, then gradually increase the reaction temperature to 85°C, stir and reflux for 3 hours; then cool the reaction solution to room temperature, filter 1. After the filter cake was fully washed with deionized water and dried at 65°C, 6.507 g of p-aminobenzoic acid salicylaldehyde Schiff base was obtained;

[0049] 2. Preparation of Schiff base palladium anion: Put the p-aminobenzoic acid salicylaldehyde Schiff base (6.507g, 0.027mol) obtained in step 1 into 200mL of absolute ethanol and fully disperse it to make a slurry, keep it at 35°C for 20min ; Then add NaOH ethanol solution (300mL, containing NaOH 1.08g, 0...

Embodiment 2

[0053] 1. Same as embodiment 1.

[0054] 2. Same as embodiment 1.

[0055] 3. Same as embodiment 1.

[0056] 4. Catalyzed oxidation Heck reaction: take three 25mL ball mill jars numbered A, B, C, add indole (131mg, 1mmol), SBNa-Pd / LDHs (97.5mg, containing Pd 0.08mmol), copper acetate (182mg, 1mmol), silica gel (600mg), 2 stainless steel balls with a diameter of 10mm, and then respectively add methyl acrylate (129mg, 1.5mmol) and ethyl acrylate (150mg, 1.5mmol) in three ball mill jars A, B, and C , tert-butyl acrylate (192mg, 1.5mmol), cover the ball mill jar lid, put into the ball mill and run at 30Hz to make the mixture react for 45 minutes, use GC-MS to measure the yield, the results are shown in Table 3.

Embodiment 3

[0058] 1. Same as embodiment 1.

[0059] 2. Same as embodiment 1.

[0060] 3. Same as embodiment 1.

[0061] 4. Catalyzed oxidation Heck reaction: take three 25mL ball mill jars numbered A, B, C, add indole (131mg, 1mmol), SBNa-Pd / LDHs (97.5mg, containing Pd 0.08mmol), copper acetate (182mg, 1mmol), silica gel (600mg), 2 stainless steel balls with a diameter of 10mm, and then respectively add methyl acrylate (258mg, 3mmol), ethyl acrylate (300mg, 3mmol), acrylic acid Tert-butyl ester (384mg, 3mmol), cover the ball mill jar lid, put into the ball mill and run at 30Hz to react the mixture for 60 minutes, use GC-MS to measure the yield, the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com