Preparation method for molybdenum-doped nanometer titanium dioxide catalyst

A nano-titanium dioxide and photocatalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of long preparation cycle and save cost and time , Uniform particle size, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Measure 10ml of tetrabutyl titanate and dissolve it in 50ml of absolute ethanol;

[0044] (2) Add 0.025g of molybdenum powder (fineness of molybdenum powder 2 μm) in the above solution;

[0045] (3) 10 ml of ammonia water with a concentration of 25% by mass was added to the above solution within 3 seconds at one time, and the butyl titanate was rapidly hydrolyzed and stirred vigorously to make the mixture uniform, and a white gel was obtained;

[0046] (4) Put the white gel into a drying oven, dry it at 60°C for 10 hours, and then grind it into powder;

[0047] (5) Put the above powder in a muffle furnace for calcination at 550° C. for 2 hours to obtain a titanium dioxide photocatalyst doped with molybdenum powder.

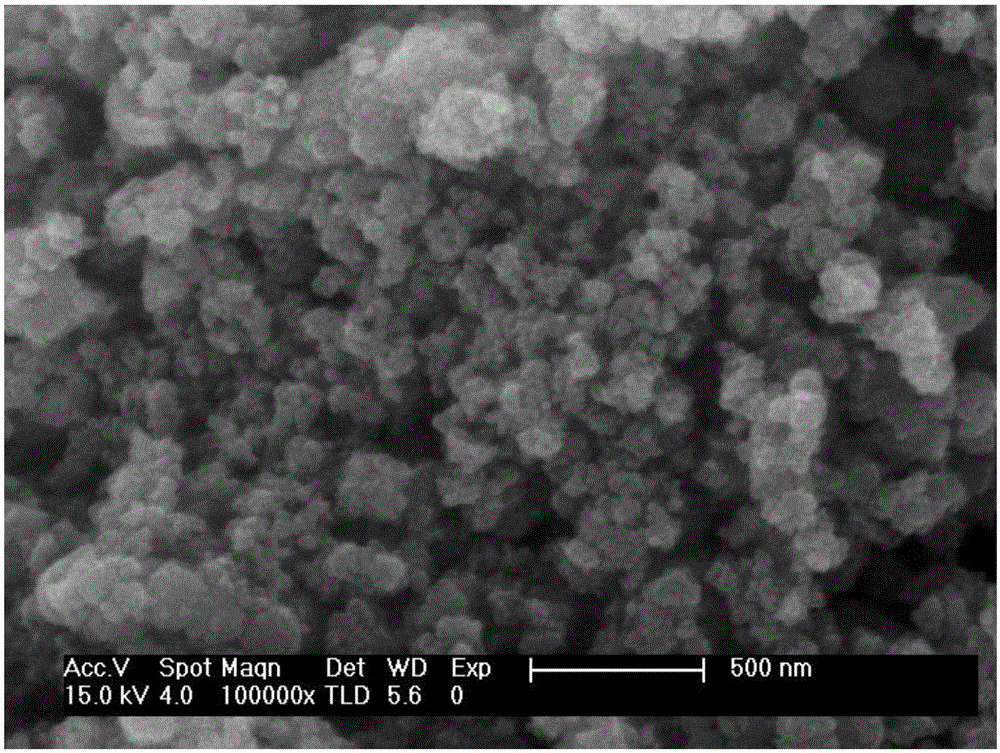

[0048] The product obtained by the reaction of step (5) is characterized by its structure and crystal form by SEM and XRD respectively, and the morphology of the titanium dioxide nano-microspheres obtained by this reaction condition is as follows figu...

Embodiment 2

[0056] (1) Measure 10ml of tetrabutyl titanate and dissolve it in 50ml of absolute ethanol;

[0057] (2) Add 0.025g of molybdenum powder (fineness of molybdenum powder 2 μm) in the above solution;

[0058] (3) Put 10 ml of ammonia water with a mass percentage concentration of 25% in the above solution within 3 seconds, quickly hydrolyze the butyl titanate and stir vigorously to make the mixture uniform;

[0059] (4) Put the precipitate into a drying oven, dry it at 60°C for 12 hours, and then grind it into powder;

[0060] (5) Put the above powder in a muffle furnace for calcination at 650° C. for 2 hours to obtain a titanium dioxide photocatalyst doped with molybdenum powder.

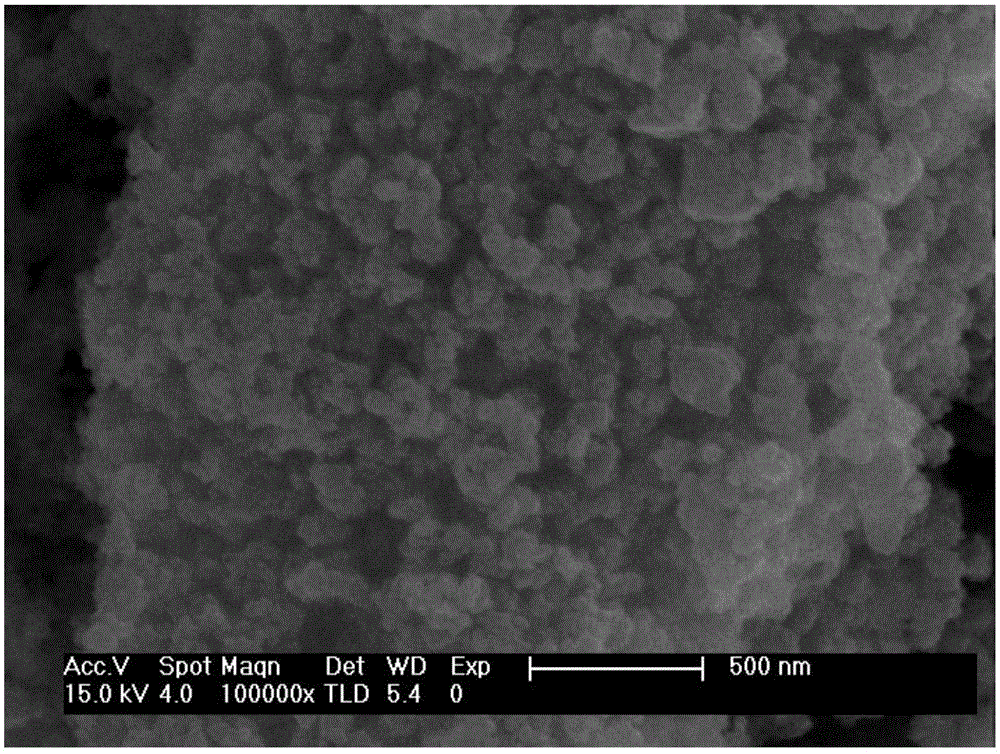

[0061] The product obtained by the reaction of step (5) is carried out in an adsorption detection experiment:

[0062] Measure 25ml of methylene blue (MB) solution with a concentration of 10mg / l and place it in a quartz test tube, weigh 25mg of titanium dioxide sample and add it to the quartz test tu...

Embodiment 3

[0066] (1) Measure 10ml of tetrabutyl titanate and dissolve it in 50ml of absolute ethanol;

[0067] (2) Add 0.035g of molybdenum powder (fineness of molybdenum powder 2 μm) in the above solution;

[0068] (3) Put 10 ml of ammonia water with a mass percentage concentration of 25% in the above solution within 3 seconds, quickly hydrolyze the butyl titanate, stir vigorously to mix evenly, and obtain a white gel;

[0069] (4) Put the white gel into a drying oven, dry it at 60°C for 10 hours, and then grind it into powder;

[0070] (5) Put the above powder in a muffle furnace for calcination at 550° C. for 2 hours to obtain a titanium dioxide photocatalyst doped with molybdenum powder.

[0071] The product obtained by the reaction of step (5) is subjected to an adsorption detection experiment similar to that of Example 2,

[0072] The absorbance spectrum of the dark reaction for 1 h is as follows: Figure 10 shown.

[0073] The product obtained by step (5) reaction is carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com