Rose flower fragrance special slurry for printing wallpapers, and production method of slurry

A technology of roses and paste, applied in the direction of coating, etc., can solve the problems of opacity, cover the pattern below, affect the color and environmental performance of the wallpaper, limit the three-dimensional aesthetic feeling of the wallpaper pattern, and achieve strong water solubility and water retention performance, improve transfer effect, improve fluidity and adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

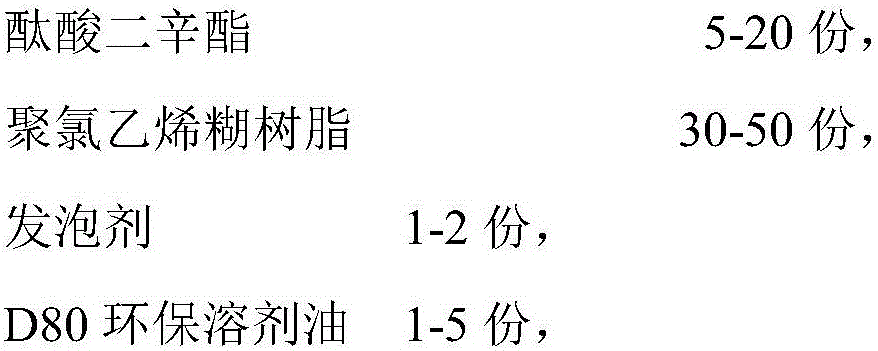

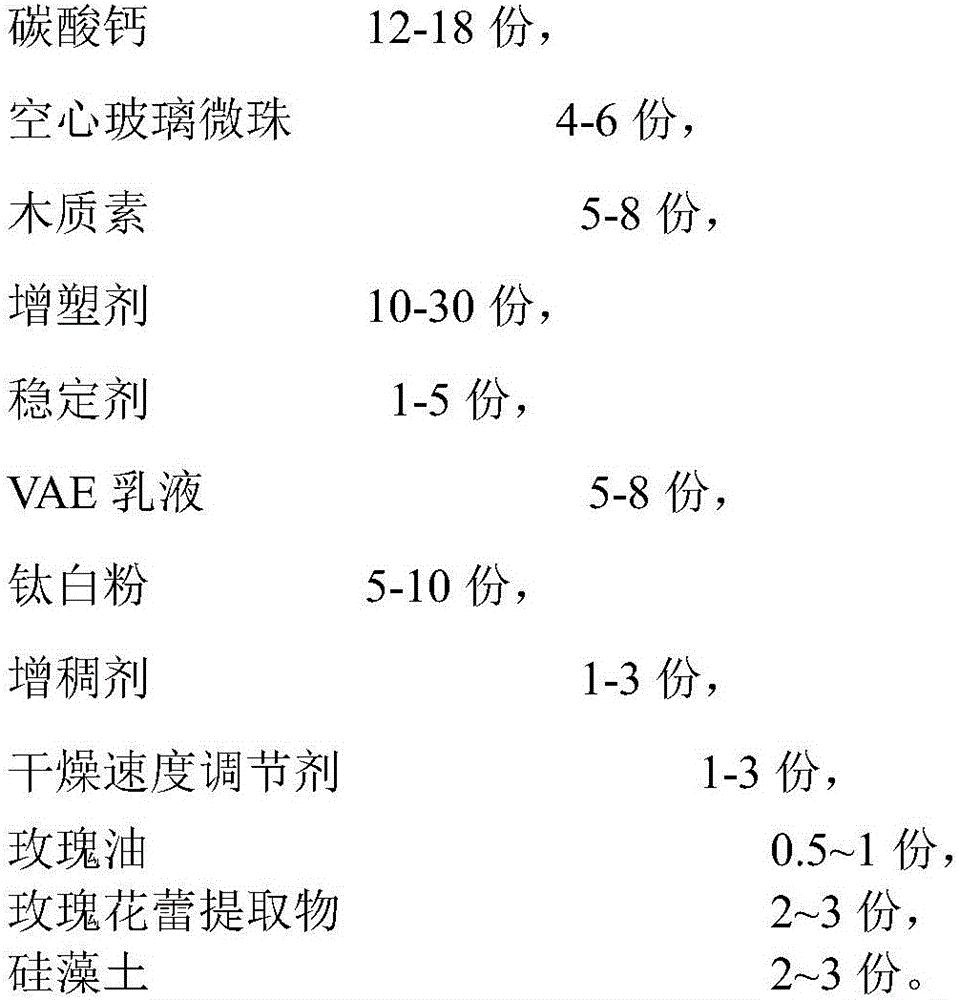

Method used

Image

Examples

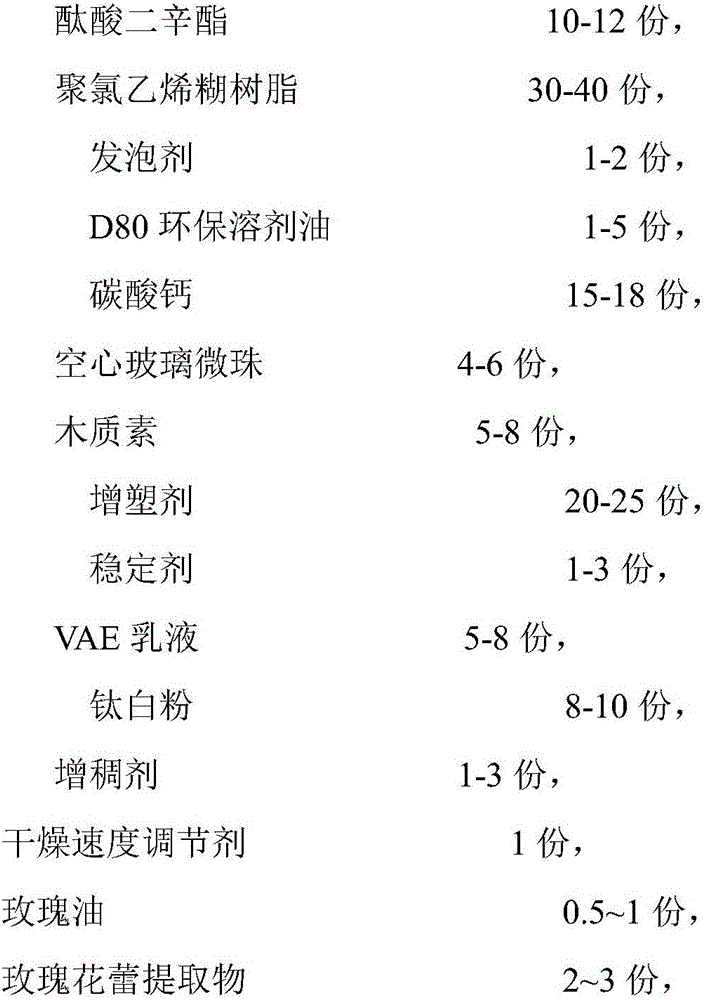

Embodiment 1

[0039] A preparation method of a special paste for rose-scented wallpaper printing, comprising the following preparation steps in turn:

[0040] Step A: add 10 parts (by weight, the same below) of dioctyl phthalate into the mixing barrel, then add 40 parts of polyvinyl chloride paste resin and stir evenly;

[0041]Step B: 2 parts of AC-410, 3 parts of D80 environmentally friendly solvent oil, 18 parts of calcium carbonate, 20 parts of epoxidized soybean oil, 2 parts of potassium-zinc composite stabilizer, 8 parts of VAE emulsion, 5 parts of Add 100% titanium dioxide into the mixing barrel, keep the rotation speed above 2000-2500r / min, and stir evenly;

[0042] Step C: add a mixture of 1 part of rose oil, 3 parts of rosebud extract and 3 parts of diatomaceous earth to the material obtained in step B, mix well, then add 6 parts of hollow glass microspheres, 8 parts of lignin, 1 part of lignin Add 1 part of lithium magnesium silicate and 1 part of n-butanol into the mixing tank ...

Embodiment 2

[0045] Step A: add 10 parts of dioctyl phthalate into the mixing barrel, then add 30 parts of polyvinyl chloride paste resin and stir evenly;

[0046] Step B: 1 part of AC-410, 1 part of D80 environmentally friendly solvent oil, 15 parts of calcium carbonate, 20 parts of epoxidized soybean oil, 1 part of potassium zinc composite stabilizer, 5 parts of VAE emulsion and 8 parts of 100% titanium dioxide is added to the mixing barrel, the speed is kept at 2000-2500r / min, and the mixing is uniform;

[0047] Step C: add a mixture of 1 part of rose oil, 2 parts of rose bud extract and 2 parts of diatomaceous earth to the material obtained in step B, and then mix 4 parts of hollow glass microspheres, 5 parts and 2 parts of lignin. Add 1 part of lithium magnesium silicate and 1 part of propylene glycol into the mixing tank, and stir evenly to obtain a slurry product; among them, the manufacturer of propylene glycol is Guangzhou Juhui Chemical Co., Ltd. The preparation method of the mi...

Embodiment 3

[0051] Step A: add 10 parts of dioctyl phthalate into the mixing barrel, then add 35 parts of polyvinyl chloride paste resin and stir evenly;

[0052] Step B: 1 part of AC-410, 3 parts of D80 environmentally friendly solvent oil, 15 parts of calcium carbonate, 25 parts of epoxidized soybean oil, 3 parts of potassium zinc composite stabilizer, 6 parts of VAE emulsion, 10 parts of 100% titanium dioxide is added to the mixing barrel, the speed is kept at 2000-2500r / min, and the mixing is uniform;

[0053] Step C: add a mixture of 0.5 part of rose oil, 2 parts of rosebud extract and 2 parts of diatomaceous earth to the material obtained in step B, mix well, then add 5 parts of hollow glass microspheres, 6 parts of lignin, 3 parts of lignin The magnesium aluminum silicate and 1 part of propylene glycol were added to the mixing tank, and stirred evenly to obtain a slurry product; among them, the magnesium aluminum silicate manufacturer was Guangzhou Bofeng Chemical Technology Co., L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com