Low-sensitivity anti-mud polycarboxylic acid water reducing agent and preparation method thereof

A technology of anti-mud type and polycarboxylic acid, which is applied in the field of concrete water-reducing agent, can solve the problems of lower compressive strength ratio, poor slump-preserving effect, and reduced water-reducing and dispersing ability, so as to ensure water-reducing and slump-preserving effect, lateral The effect of uniform chain distribution and high double bond retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

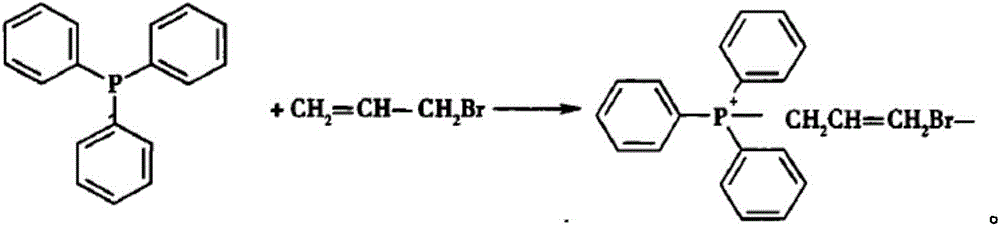

Method used

Image

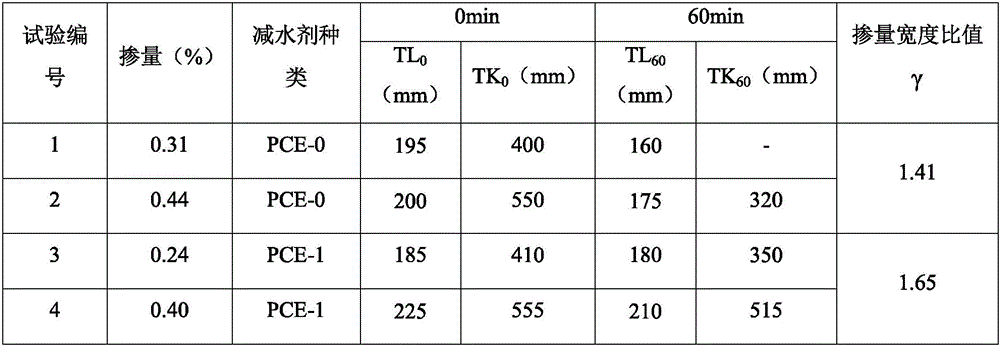

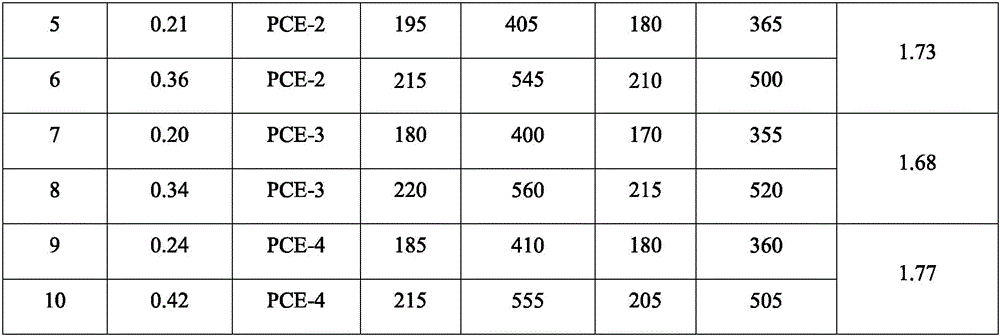

Examples

Embodiment 1

[0034] (1) Weigh each raw material component by the following parts by weight: 110 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene base ether (molecular weight 2000), 8 parts by weight of acrylic acid, 6 parts by weight of hydroxyethyl acrylate, unsaturated amphoteric 2 parts by weight of quaternary phosphorus salt, 0.5 parts by weight of hydrogen peroxide, Brüggolit TM 0.7 parts by weight of FF6, 0.04 parts by weight of ferrous sulfate, 0.35 parts by weight of thioglycolic acid, 4 parts by weight of potassium hydroxide aqueous solution of 50% mass concentration, 5 parts by weight of sodium hydroxide aqueous solution of 32% mass concentration, and the rest are deionized water , adjusted to 50% solid content.

[0035] (2) Dissolve acrylic acid and mercaptoacetic acid in 15 parts by weight of deionized water, and adjust the pH to 5.5 to 6.0 with a 50% mass concentration of potassium hydroxide aqueous solution to obtain the first solution; Brüggolit TM FF6 was dissolve...

Embodiment 2

[0040] (1) Weigh 110 parts by weight of each raw material component 4-hydroxybutyl vinyl polyoxyethylene ether (molecular weight 2400), 6 parts by weight of acrylic acid, 3 parts by weight of hydroxyethyl methacrylate, unsaturated 1 weight part of amphoteric quaternary phosphonium salt, 0.6 weight part of sodium persulfate, 0.8 weight part of sodium formaldehyde sulfoxylate, 0.02 weight part of ferrous nitrate, 0.4 weight part of mercaptopropionic acid, 2 weights of potassium hydroxide aqueous solution of 50% mass concentration part, 6 parts by weight of sodium hydroxide aqueous solution of 32% mass concentration, and the rest is deionized water, which is adjusted to 50% solid content.

[0041] (2) Dissolve acrylic acid and mercaptopropionic acid in 15 parts by weight of deionized water, and adjust the pH to 5.5 to 6.0 with an aqueous potassium hydroxide solution of 50% mass concentration to obtain the first solution; dissolve sodium formaldehyde sulfoxylate in 15 The second s...

Embodiment 3

[0046] (1) Each raw material component is weighed by the following parts by weight: 100 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene ether (molecular weight 4000), 7 parts by weight of methacrylic acid, 4 parts by weight of hydroxypropyl acrylate, no 3 parts by weight of saturated amphoteric quaternary phosphonium salt, 0.4 part by weight of ammonium persulfate, Brüggolit TM 0.7 parts by weight of FF6, 0.06 parts by weight of ferrous nitrate, 0.5 parts by weight of mercaptoethanol, 3 parts by weight of potassium hydroxide aqueous solution of 50% mass concentration, 4 parts by weight of sodium hydroxide aqueous solution of 32% mass concentration, and all the other are deionized water, Adjust to 50% solids.

[0047] (2) methacrylic acid and mercaptoethanol are dissolved in 15 parts by weight of deionized water, and the pH is adjusted to 5.5 to 6.0 with a 50% mass concentration of potassium hydroxide aqueous solution to obtain the first solution; TM FF6 was dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com