Preparation methods of alkaline polyether monomer and polycarboxylate water reducer

A technology of polycarboxylic acid and water reducer, which is applied in the field of concrete admixtures, and can solve problems such as increasing difficulty and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

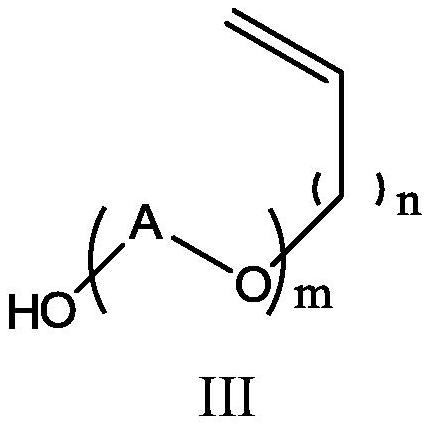

Image

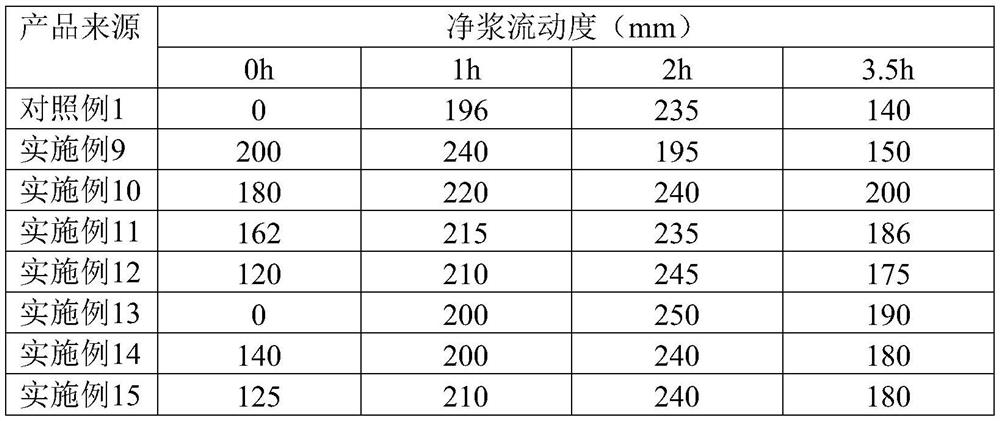

Examples

Embodiment 1

[0068] Put vinyl glycol ether into a stainless steel high-pressure reaction kettle, the input amount is 564.46g, add 3.63g of potassium hydroxide solid, replace with nitrogen, then turn on the heating under stirring, and start to slowly pass into the reactor after the temperature rises to 110°C Add 2638.55g of ethylene oxide to carry out polymerization reaction, maintain the temperature at 110°C, and keep the pressure relatively constant at about 0.3MPa until all the ethylene oxide is added into the reactor and keep it warm for about 1 hour until the pressure of the reactor no longer drops. After vacuuming and degassing, the temperature was lowered to 80° C., and the material was discharged to obtain intermediate 1 with a molecular weight of 482.

Embodiment 2

[0070]Put diethylene glycol monovinyl ether into a stainless steel high-pressure reaction kettle, the input amount is 217.84g, add 1.15g of potassium hydroxide solid, replace with nitrogen, then turn on the heating under stirring, and start slowly to the reactor after the temperature rises to 110°C Introduce 935.97g of ethylene oxide into the reactor for polymerization, maintain the temperature at 110°C, and keep the pressure relatively constant at about 0.3MPa, until all the ethylene oxide is added into the reactor, and keep it warm for about 1 hour, until the pressure of the reactor no longer drops Time. After vacuuming and degassing, the temperature was lowered to 80° C., and the material was discharged to obtain intermediate 2 with a molecular weight of 675.

Embodiment 3

[0072] Put vinyl glycol ether into a stainless steel high-pressure reaction kettle with an input amount of 367.21g, add 3.81g of potassium hydroxide solid, replace with nitrogen, then turn on the heating under stirring, and start to slowly pass into the reactor after the temperature rises to 110°C Add 2974.06g of ethylene oxide to carry out polymerization reaction, maintain the temperature at 110°C, and keep the pressure relatively constant at about 0.3MPa until all the ethylene oxide is added into the reactor and keep it warm for about 1 hour until the pressure of the reactor no longer drops. After vacuuming and degassing, the temperature was lowered to 80° C., and the material was discharged to obtain intermediate 3 with a molecular weight of 768.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com