Integrated styrene acrylic latex, preparation method and application

A technology of styrene-acrylic latex and large monomers, which is applied in the field of oil drilling and cementing, can solve problems such as difficult adjustments, and achieve the effects of improving cementing quality, reducing fluid loss, and reducing the difficulty of adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

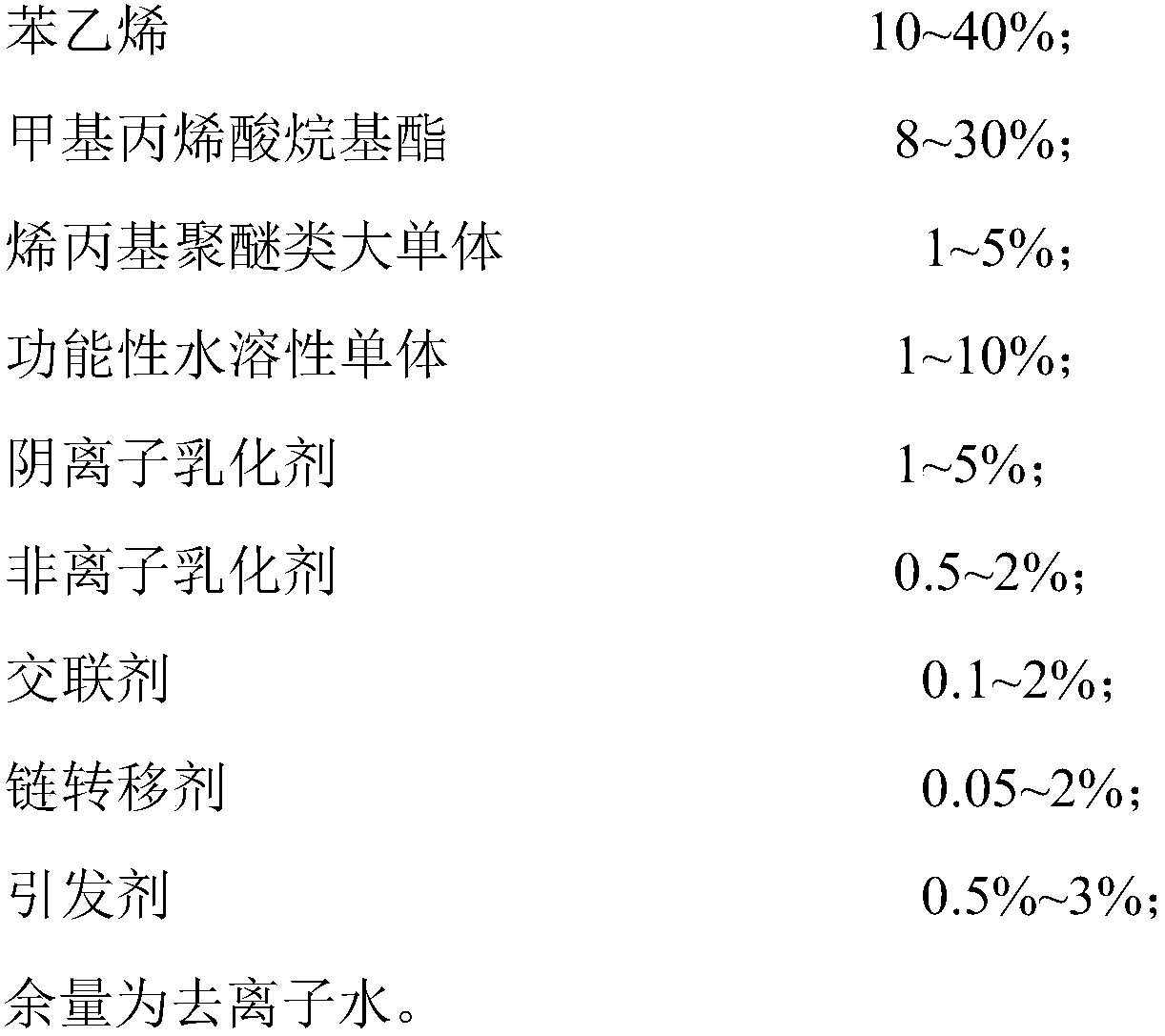

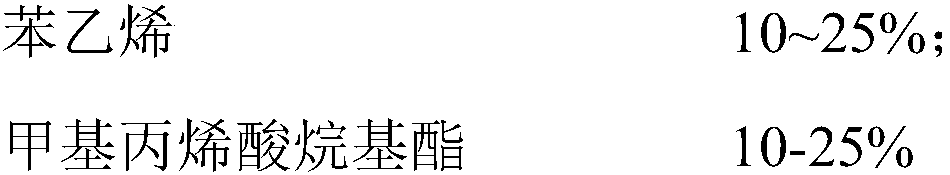

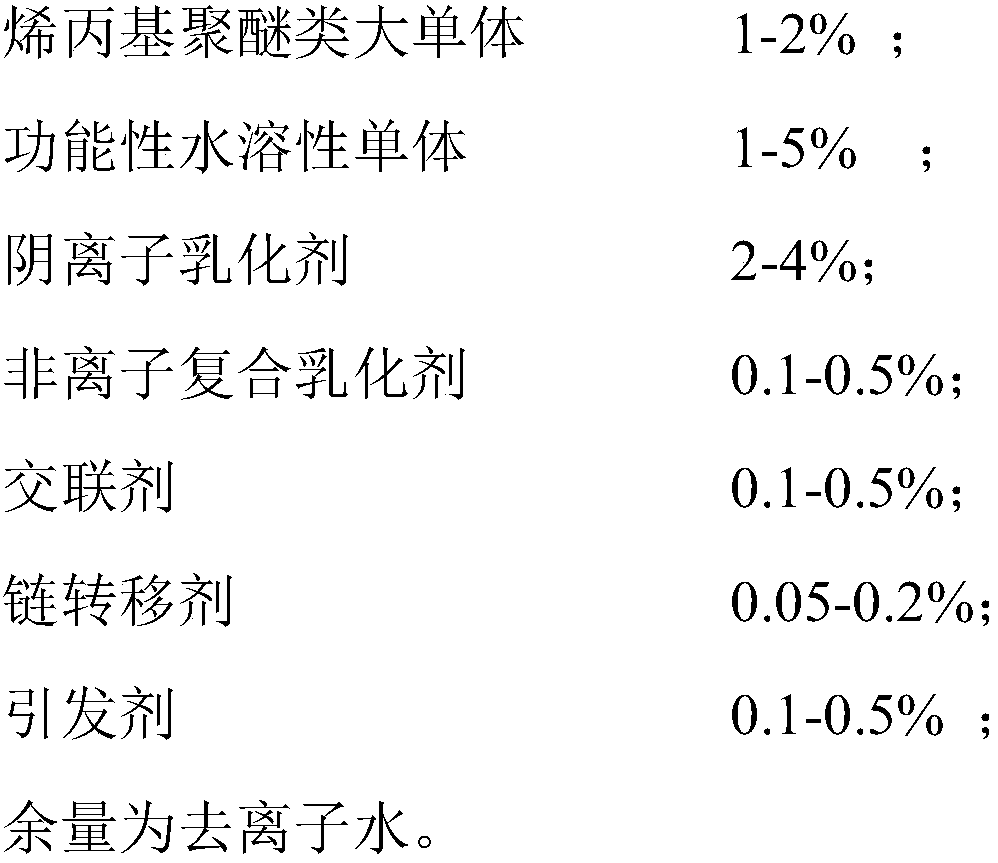

Method used

Image

Examples

Embodiment 1

[0065] Add 750kg deionized water, 20kg alkylsulfonate anionic emulsifier SCAY-10 (self-made by the Academy of Engineering), 20kg nonionic emulsifier octylphenol polyoxyethylene ether TX-50 in the reactor (raw material tank) with stirring, 30g anionic emulsifier nonylphenol polyoxyethylene ammonium sulfate CO458, 40g anionic emulsifier sodium dodecylbenzenesulfonate, 600kg styrene, 300kg butyl acrylate, 12kg crosslinking agent divinylbenzene, 60kg functional mono Body NN dimethylacrylamide, 50kg allyl polyoxyethylene ether macromonomer HPEG2400, fully sheared and pre-emulsified for 1 hour before use. Add initiator sodium persulfate 10kg in another raw material dropping tank simultaneously, deionized water 650kg, as initiator component.

[0066] Put 200kg of deionized water into the reactor, raise the temperature to 90°C, add 10% of the above-mentioned pre-emulsion, 4% of the above-mentioned initiator solution, and after 20 to 30 minutes of reaction, start to drop the remaining ...

Embodiment 2

[0068] Add 750kg deionized water, 20kg alkylsulfonate anionic emulsifier SCAY-10 (self-made by the Engineering Institute) in the stirred reactor (raw material tank), 20kg nonionic emulsifier octylphenol polyoxyethylene ether OP-10, 30g anionic emulsifier nonylphenol polyoxyethylene ammonium sulfate CO458, 40g anionic emulsifier sodium dodecylbenzenesulfonate, 500kg styrene, 400kg butyl acrylate, 12kg crosslinking agent divinylbenzene, 60kg functional mono 2-acrylamide-2-methylpropanesulfonic acid AMPS, 50kg allyl polyoxyethylene ether macromonomer TPEG1300, fully sheared and pre-emulsified for 1 hour before use. Add initiator sodium persulfate 10kg in another raw material dropping tank simultaneously, deionized water 650kg, as initiator component.

[0069] Put 200kg of deionized water into the reactor, raise the temperature to 90°C, add 10% of the above-mentioned pre-emulsion, 4% of the above-mentioned initiator solution, and after 20 to 30 minutes of reaction, start to drop t...

Embodiment 3

[0071] Add 750kg deionized water, 30kg alkylsulfonate anionic emulsifier SCAY-10 (self-made by the Engineering Institute) in the stirred reactor (raw material tank), 10kg nonionic emulsifier octylphenol polyoxyethylene ether OP-10, 30g anionic emulsifier nonylphenol polyoxyethylene ammonium sulfate CO458, 40g anionic emulsifier sodium dodecylsulfonate, 300kg styrene, 300kg 2-ethylhexyl acrylate, 300kg dodecyl acrylate , 12kg cross-linking agent divinylbenzene, 60kg 2-acrylamide-2-methylpropanesulfonic acid AMPS, 50kg allyl polyoxyethylene ether macromonomer HPEG2400, fully sheared and pre-emulsified for 1 hour for use. Add initiator sodium persulfate 15kg in another raw material dropping tank simultaneously, deionized water 650kg, as initiator component.

[0072] Put 200kg of deionized water into the reactor, raise the temperature to 90°C, add 10% of the above-mentioned pre-emulsion, 4% of the above-mentioned initiator solution, and after 20 to 30 minutes of reaction, start to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com