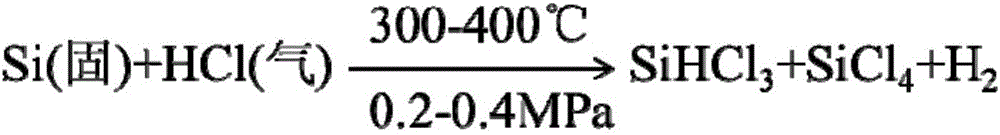

Catalyst for producing trichlorosilane with silicon-hydrogen chlorination process, preparation method of catalyst and method for catalytically producing trichlorosilane

A technology of trichlorosilane and catalyst, applied in metal/metal oxide/metal hydroxide catalyst, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the decrease of synthesis efficiency , high reaction temperature and high energy consumption, to achieve the effect of increasing adsorption capacity, improving selectivity and reducing activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The catalyst is 80wt% Cu+20wt% Zn, granular, with a particle size of 0.5-10 μm;

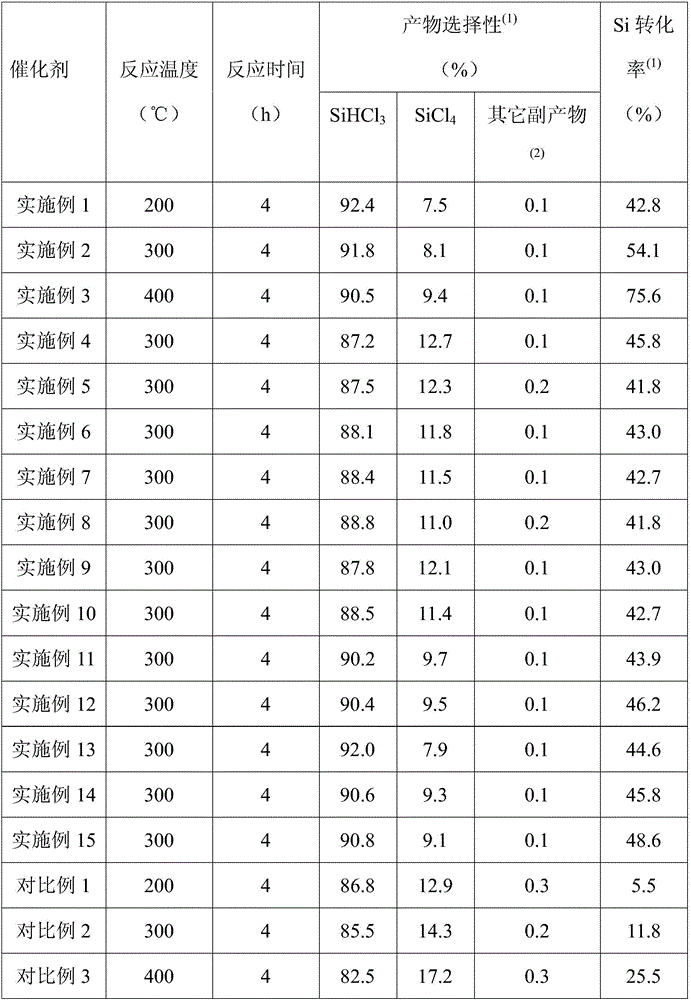

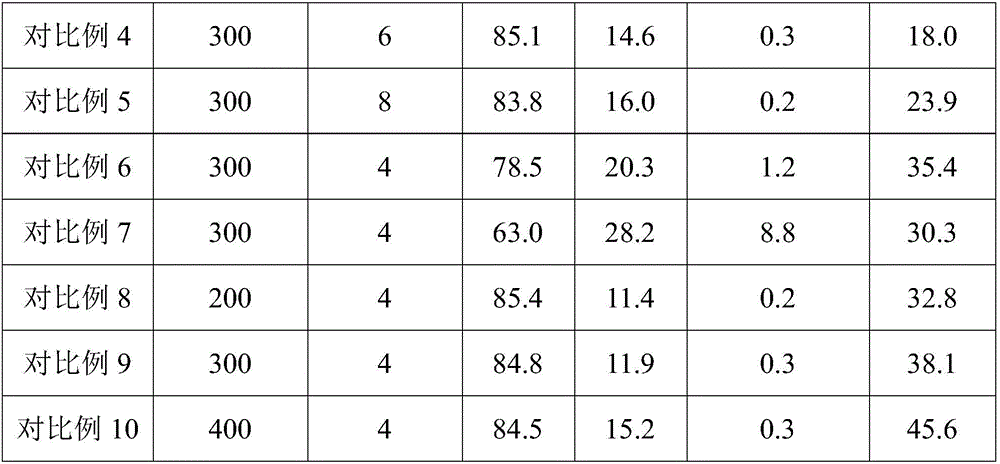

[0050] The catalyst is used to catalyze the method for producing trichlorosilane: in a fixed bed (the inner diameter of the reactor is 20cm, and the length is 50cm), add the homogeneous mixture of 20g Si powder and 0.02g catalyst earlier, pass into N 2 Purge the reaction system for 1 hour; then raise the temperature to 200°C, feed HCl, the flow rate is 15mL / min, the reaction pressure is 0.1MPa, and the reaction time is 4 hours; after the reaction product is condensed by the condenser tube, it is collected with toluene, and the excess tail gas is collected with alkali After the liquid was absorbed, it was emptied; the collected mixed solution was constant volume and then quantitatively analyzed by capillary gas chromatography (Agilent 7890A, KB-210 chromatographic column, TCD detector); SiHCl in the resulting product 3 The content of Si is 92.4%, and the conversion rate of Si is 42.8% (see ...

Embodiment 2

[0054] The catalyst is 80wt% Cu+20wt% Zn, granular, with a particle size of 0.5-10 μm;

[0055] The catalyst is used to catalyze the method for producing trichlorosilane: in a fixed bed (the inner diameter of the reactor is 20cm, and the length is 50cm), add the homogeneous mixture of 20g Si powder and 0.02g catalyst earlier, pass into N 2 Purge the reaction system for 1 hour; then raise the temperature to 300°C, feed HCl, the flow rate is 15mL / min, the reaction pressure is 1MPa, and the reaction time is 4 hours; the product after the reaction is collected with toluene after being condensed by a condenser tube, and the excess tail gas is collected with lye Empty after absorption; the collected mixed solution is quantitatively analyzed by capillary gas chromatography (Agilent 7890A, KB-210 chromatographic column, TCD detector) after constant volume; SiHCl in the resulting product 3 The content of Si is 91.8%, and the conversion rate of Si is 54.1% (see Table 1).

Embodiment 3

[0057] The catalyst is 80wt% Cu+20wt% Zn, granular, with a particle size of 0.5-10 μm;

[0058] The catalyst is used to catalyze the method for producing trichlorosilane: in a fixed bed (the inner diameter of the reactor is 20cm, and the length is 50cm), add the homogeneous mixture of 20g Si powder and 0.02g catalyst earlier, pass into N 2Purge the reaction system for 1 hour; then raise the temperature to 400°C, feed HCl, the flow rate is 15mL / min, the reaction pressure is 2MPa, and the reaction time is 4 hours; the product after the reaction is collected with toluene after being condensed by a condenser tube, and the excess tail gas is collected with lye Empty after absorption; the collected mixed solution is quantitatively analyzed by capillary gas chromatography (Agilent 7890A, KB-210 chromatographic column, TCD detector) after constant volume; SiHCl in the resulting product 3 The content of Si is 90.5%, and the conversion rate of Si is 75.6% (see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com