Alcohol-based fuel with high calorific value

An alcohol-based fuel, high calorific value technology, used in fuels, liquid carbon-containing fuels, petroleum industry, etc., can solve problems such as unsatisfactory calorific value, and achieve the effects of preventing stratification, increasing calorific value, and promoting full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

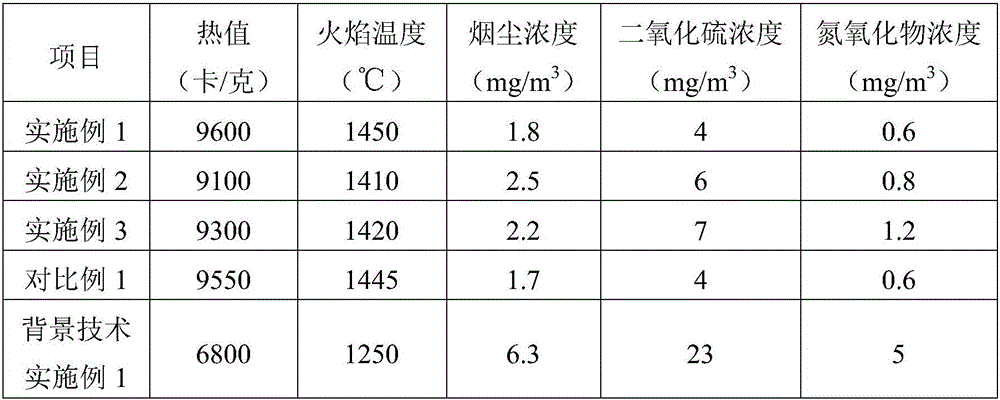

Examples

Embodiment 1

[0017] A high calorific value alcohol-based fuel, made of the following components in parts by weight: 80 parts of methanol, 3 parts of isopropanol, 2 parts of isoamyl alcohol, 0.6 parts of polyethylene glycol, 2 parts of petroleum ether, tertiary 0.7 parts of amyl methyl ether, 2 parts of cumene hydrogen peroxide, 0.02 parts of ethylene-vinyl acetate copolymer, 0.03 parts of calcium stearate, 0.4 parts of ethyl acetate, 0.5 parts of nano-magnesium powder, 0.3 parts of nano-iron oxide Copies.

[0018] The particle size of the nano-magnesium powder and nano-iron oxide is 80nm, and the processing is performed according to the following steps:

[0019] First add the nanomaterials to ethanol, and place them on an ultrasonic machine with a frequency of 35KHz for 25 minutes, then sonicate the silane coupling agent and polyoxyethylene sorbitan monostearate for 20 minutes, and then place them at 95°C. In a water bath, react for 2 hours, and finally ultrasonicate for 12 minutes, centrifuge...

Embodiment 2

[0022] A high calorific value alcohol-based fuel, made of the following components in parts by weight: 75 parts of methanol, 2 parts of isopropanol, 1 part of isoamyl alcohol, 0.4 parts of polyethylene glycol, 1 part of petroleum ether, tertiary 0.6 parts of amyl methyl ether, 1 part of cumene hydrogen peroxide, 0.01 parts of ethylene-vinyl acetate copolymer, 0.02 parts of calcium stearate, 0.2 parts of ethyl acetate, 0.3 parts of nano-magnesium powder, 0.2 parts of nano-iron oxide Copies.

[0023] The particle size of the nano-magnesium powder and nano-iron oxide is 60nm, and the processing is performed according to the following steps:

[0024] First add the nanomaterials to ethanol, and place them on an ultrasonic machine with a frequency of 30KHz for 20 minutes, then sonicate the silane coupling agent and polyoxyethylene sorbitan monostearate for 15 minutes, and then place them at 90°C. In a water bath, react for 1 hour, and finally sonicate for 10 minutes, centrifuge, filter,...

Embodiment 3

[0027] A high calorific value alcohol-based fuel, which is made of the following components in parts by weight: 85 parts of methanol, 4 parts of isopropanol, 3 parts of isoamyl alcohol, 0.8 parts of polyethylene glycol, 3 parts of petroleum ether, tertiary 0.8 parts of amyl methyl ether, 3 parts of cumene hydrogen peroxide, 0.03 parts of ethylene-vinyl acetate copolymer, 0.04 parts of calcium stearate, 0.5 parts of ethyl acetate, 0.7 parts of nano-magnesium powder, 0.4 parts of nano-iron oxide Copies.

[0028] The particle size of the nano-magnesium powder and nano-iron oxide is 100 nm, and the processing is performed according to the following steps:

[0029] First add the nanomaterial to ethanol, and place it on a 40KHz ultrasonic machine for 30 minutes, then sonicate the silane coupling agent and polyoxyethylene sorbitan monostearate for 25 minutes, and then place it at 100°C. In a water bath, react for 3 hours, and finally ultrasound for 15 minutes, centrifuge, filter, and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com