Graphene aerogel loaded two-phase transition metal sulfide as well as preparation method and application thereof

A graphene aerogel, transition metal technology, applied in electrical components, electrochemical generators, structural parts, etc., can solve problems such as limiting the reversible specific capacity of composite electrodes, achieve good cycle stability, improve electrical conductivity, Avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Weigh 1.746g nickel nitrate hexahydrate Ni(NO 3 ) 2 ·6H 2 O (0.006mol) and 0.873g cobalt nitrate hexahydrate Co(NO 3 ) 2 ·6H 2 O (0.003mol) (Ni:Co=2:1) was dissolved in 100mL of deionized water, ultrasonicated for 10min, and mixed metal salt solution A was prepared.

[0053] 2. Dissolve the synthesized graphite oxide in 50mL of deionized water, and sonicate for 2 hours to obtain a delaminated graphite oxide aqueous solution. The graphite oxide aqueous solution after peeling was poured into the above-mentioned mixed metal salt solution A, and stirred for 2 hours to obtain a mixed solution B (the amount of graphene oxide is 5% of the mass sum of nickel nitrate and cobalt nitrate).

[0054] 3. Add ammonia water with a mass fraction of 1% dropwise into the above mixed solution B to adjust the pH to 6.5.

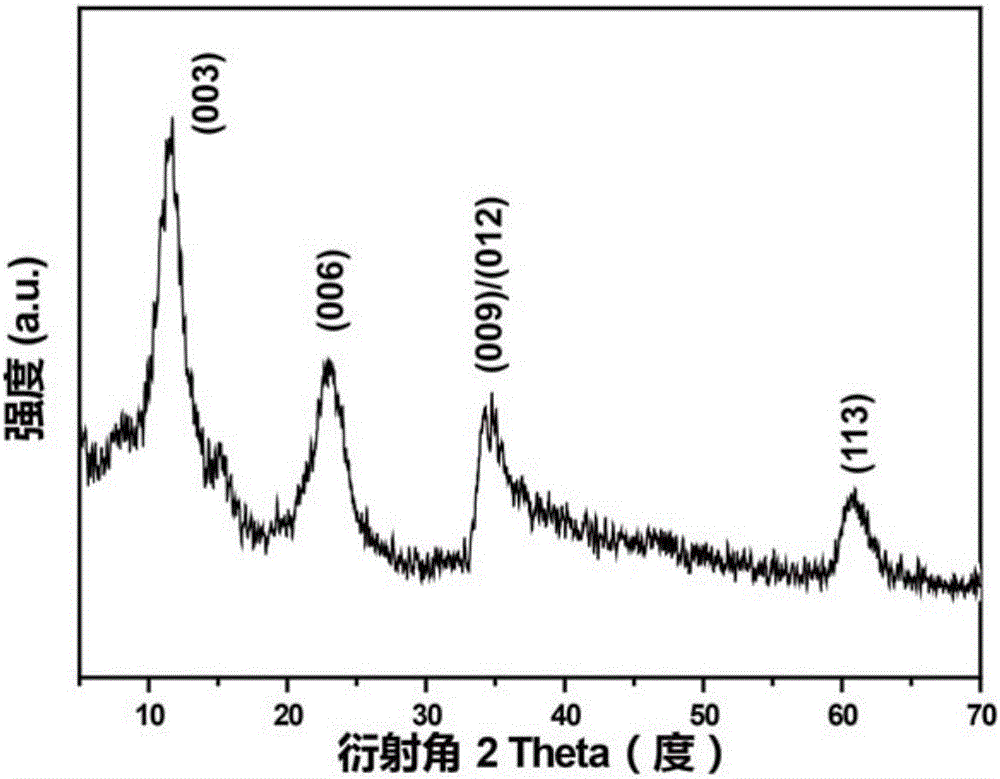

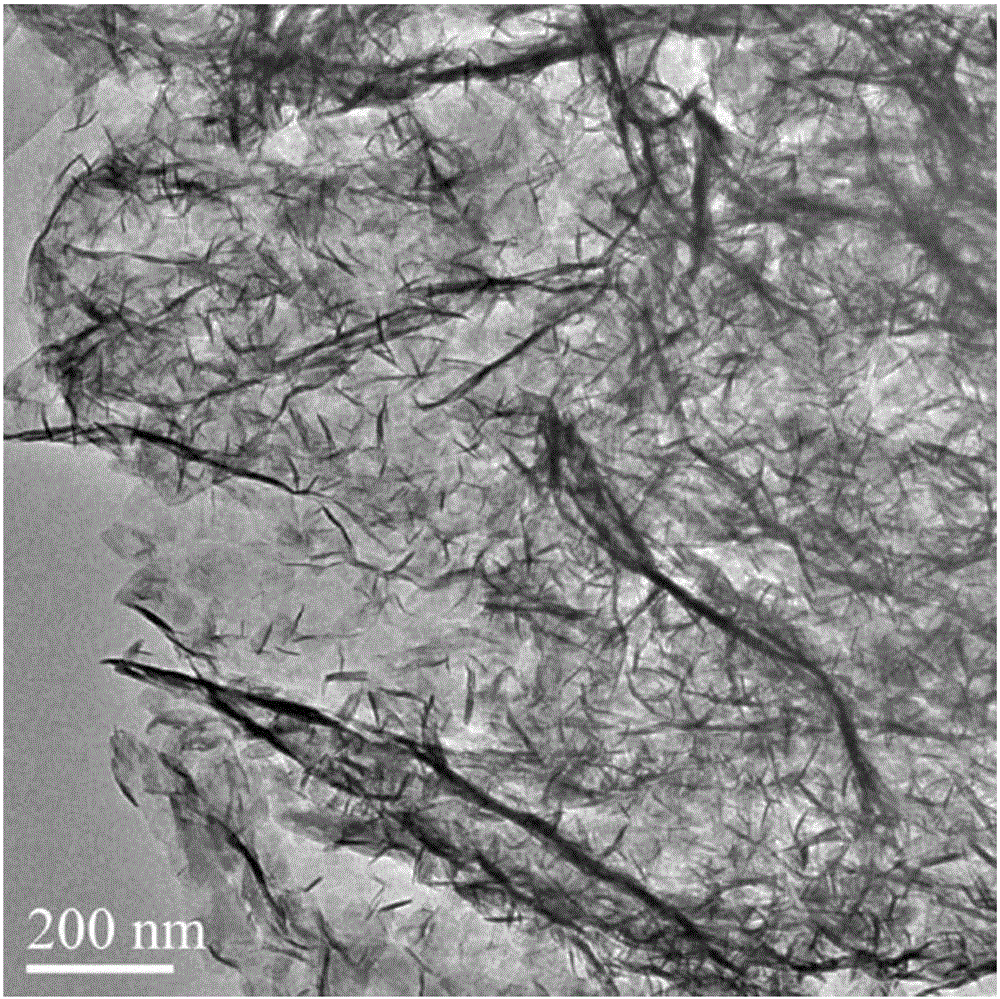

[0055] 4. Then transfer to a 100mL reactor, and conduct hydrothermal treatment at 150°C for 24h. After being naturally cooled to room temperature, centrifuged,...

Embodiment 2

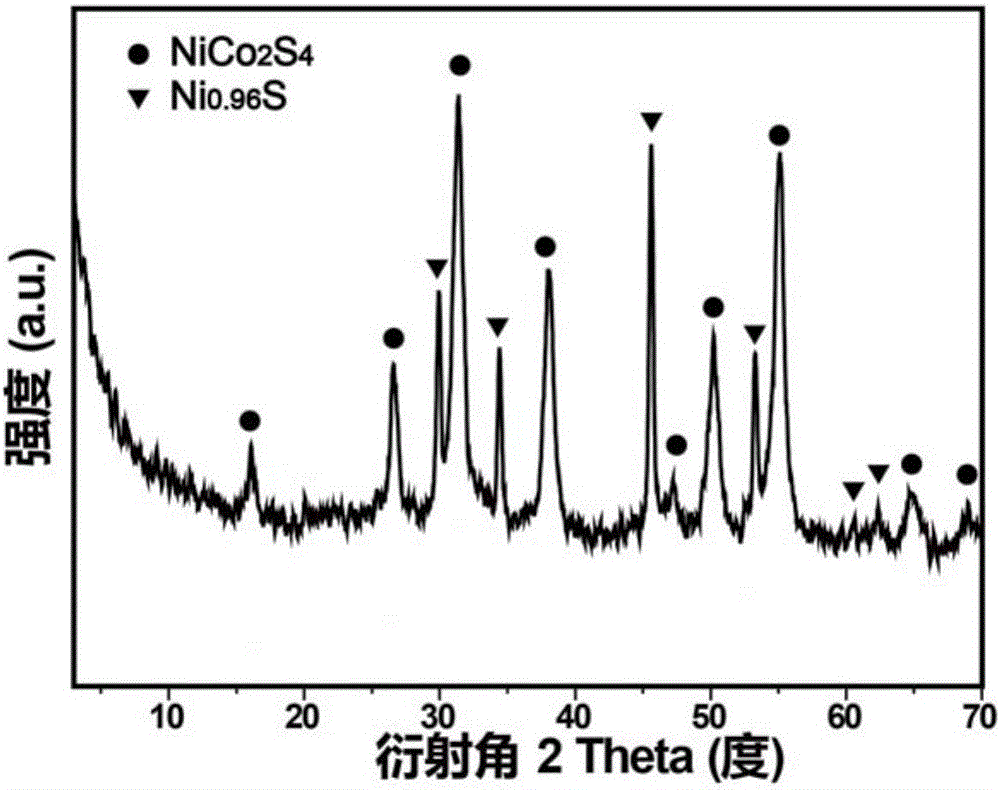

[0063] Other conditions are identical with embodiment 1, and difference is only to take by weighing 2.6171g nickel nitrate hexahydrate Ni (NO 3 ) 2 ·6H 2 O. (Ni:Co=3:1) to get NiCo 2 S 4 / 3Ni 0.96 S / 3DGA (NiCo 2 S 4 : Ni 0.96 S=1:5.21) The battery test results are summarized in Table 1. The battery test results are summarized in Table 1.

Embodiment 3

[0065] Other conditions are identical with embodiment 1, and difference is only to take by weighing 3.490g nickel nitrate hexahydrate Ni (NO 3 ) 2 ·6H 2 O. (Ni:Co=4:1)NiCo 2 S 4 / 3Ni 0.96 S / 3DGA (NiCo 2 S 4 : Ni 0.96 S=1:7.29). The battery test results are summarized in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com