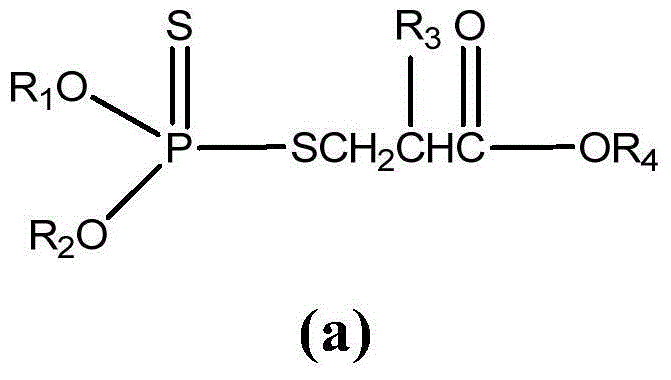

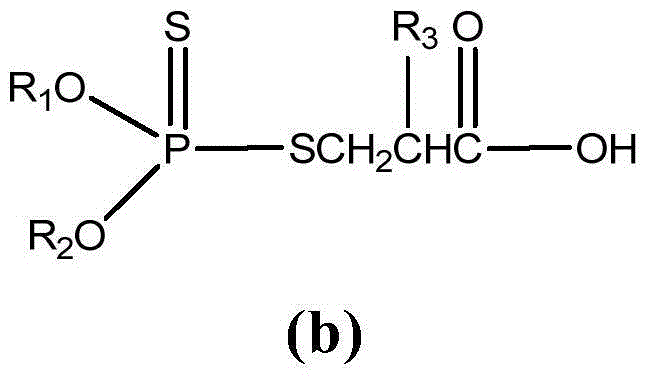

Phosphorothioate type antiwear agent

A compound and straight-chain technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve problems such as poor thermal stability, clogged filters, high acidity of water layer, etc., and achieve excellent anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0049] Example 1 Diisooctyl dithiophosphoric acid-2-methyl-succinic acid dimethyl ester (AW-1)

[0050]

[0051] Under nitrogen protection, 70.8g of bis(2-ethylhexyl)dithiophosphoric acid was added to a 250ml four-necked reaction flask, heated to 100°C, and then 7.08g of p-toluenesulfonic acid was added as a catalyst, and then stirred and used 1.5 31.2 g of dimethyl itaconic acid was slowly added dropwise over a period of hours, and the reaction was continued to stir for 8 hours under nitrogen protection to obtain a crude product.

[0052] Separation and purification: the above crude product was extracted with 10wt% sodium carbonate aqueous solution and petroleum ether in turn, and the oil phase was dried with anhydrous sodium sulfate, filtered, and then distilled under reduced pressure. The liquid distilled under reduced pressure was separated by silica gel chromatography. The inner diameter of the chromatography column is 35 mm and the height is 400 mm, the adsorbent is ...

Embodiment 2 2

[0053] Example 2 Diisooctyl dithiophosphoric acid-2-methyl-succinic acid diethyl ester (AW-2)

[0054]

[0055] Under nitrogen protection, 70.8g of bis(2-ethylhexyl)dithiophosphoric acid was added to a 250ml four-necked reaction flask, heated to 100°C, and then 7.08g of p-toluenesulfonic acid was added as a catalyst, and then stirred and used 1.5 36.8 g of itaconic acid diethyl ester was slowly added dropwise over a period of hours, and the reaction was continued to stir for 9 hours under nitrogen protection to obtain a crude product.

[0056] Separation and purification: the above crude product was washed with 10wt% sodium carbonate aqueous solution, then extracted with petroleum ether, and the oil phase was dried with anhydrous sodium sulfate, filtered, and then distilled under reduced pressure. The liquid distilled under reduced pressure was separated by silica gel chromatography. The inner diameter of the chromatography column is 35 mm and the height is 400 mm, the ads...

Embodiment 3 2

[0057] Example 3 Diisooctyl dithiophosphoric acid-2-methyl-succinic acid dibutyl ester (AW-3)

[0058]

[0059] Under nitrogen protection, 70.8g of bis(2-ethylhexyl)dithiophosphoric acid was added to a 250ml four-necked reaction flask, heated to 100°C, and then 7.08g of p-toluenesulfonic acid was added as a catalyst, and then stirred and used 1.5 48.0 g of itaconic acid dibutyl ester was slowly added dropwise over a period of 10 hours, and the reaction was then continued to stir for 10 hours under nitrogen protection to obtain a crude product.

[0060] Separation and purification: the above crude product was washed with 10wt% sodium carbonate aqueous solution, then extracted with petroleum ether, and the oil phase was dried with anhydrous sodium sulfate, filtered, and then distilled under reduced pressure. The liquid distilled under reduced pressure was separated by silica gel chromatography. The inner diameter of the chromatography column is 35 mm and the height is 400 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com