Composite solid electrolyte, flexible all-solid-state battery, preparation method and wearable electronic device

A solid-state electrolyte and all-solid-state battery technology, which can be used in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and electrolyte immobilization/gelation. , reduce the internal resistance and increase the effect of the contact interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In this embodiment, the positive electrode active material adopts nickel-cobalt-manganese ternary material (LiNi 0.5 co 0.2 mn 0.3 o 2 ), the polymer matrix is polyethylene oxide, the lithium salt is lithium ammonium trifluoromethanesulfonate, and the conductive additive is indium oxide. After mixing the four raw materials in acetonitrile at a mass ratio of 5:1:1:3, the room temperature The mixture was stirred for 12 hours to obtain a composite positive electrode slurry. The composite cathode slurry was vacuum-dried at 60°C for 12 hours to obtain a composite cathode precursor powder, and finally the composite cathode precursor powder was pressed under a pressure of 4 MPa to obtain a composite cathode sheet with a thickness of 200 microns.

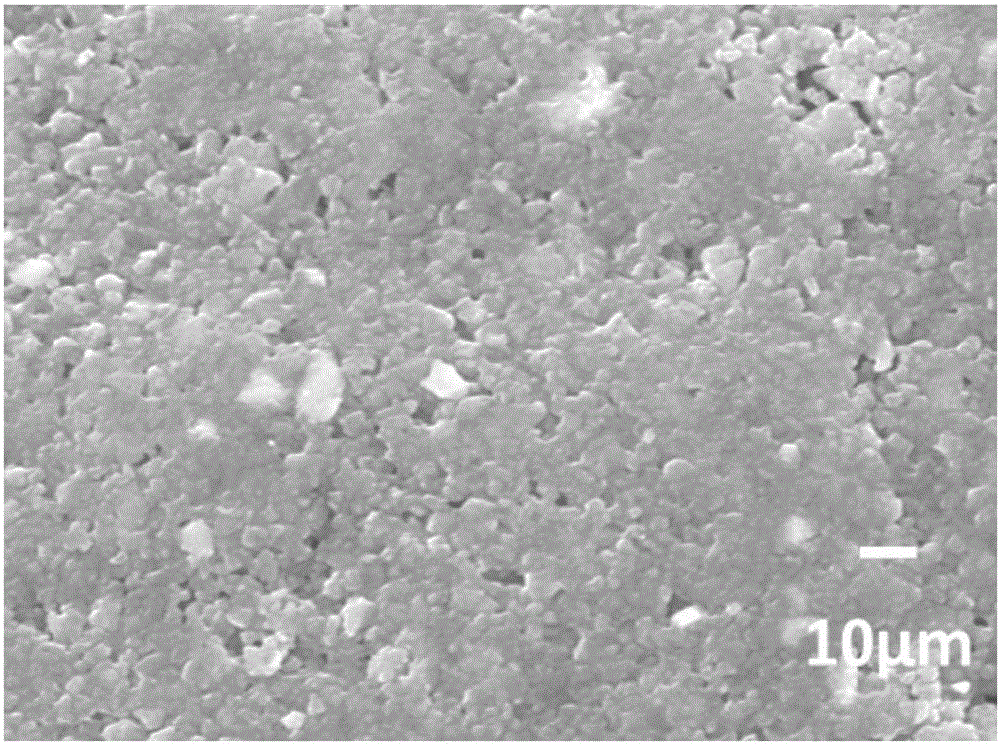

[0062] The cross-sectional scanning electron microscope figure of the composite positive electrode sheet of this embodiment, as figure 1 shown. Depend on figure 1 It can be seen that the composite positive electrode sheet pre...

Embodiment 2

[0064] In this example, lithium cobaltate is used as the positive electrode active material, chlorohydrin rubber as the polymer matrix, lithium perchlorate is selected as the lithium salt, and indium oxide is used as the conductive additive. The mass ratio of the four raw materials is 2:1:1: 1 was mixed in acetone and stirred at room temperature for 12 hours to obtain a composite positive electrode slurry. The composite positive electrode slurry was directly coated on the aluminum foil, and dried under vacuum at 60° C. for 12 hours to obtain a composite positive electrode sheet with a thickness of 20 μm.

Embodiment 3

[0066] In this example, the positive electrode active material is lithium iron phosphate, the polymer matrix is polyethylene oxide, the lithium salt is lithium hexafluorophosphate, and the conductive additive is conductive graphite. The mass ratio of the four raw materials is 36:1:1:2. After mixing with nitrile, the mixture was stirred at room temperature for 12 hours to obtain a composite positive electrode slurry. The composite positive electrode slurry was vacuum-dried at 60°C for 12 hours to obtain a composite positive electrode precursor powder, and finally the composite positive electrode precursor powder was pressed under a pressure of 6 MPa to obtain a composite positive electrode sheet with a thickness of 1000 microns

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com