Preparation method of electrochemical sensor with surface curing polypeptide probe

A surface curing and electrochemical technology, applied in scientific instruments, instruments, material analysis by electromagnetic means, etc., can solve the requirements of extremely high surface flatness of metal electrodes, change the third- and fourth-order structures of polypeptides, and be unfavorable for large-scale safety. Production and other issues, to achieve the effect of retaining the effective activity and sensor sensitivity, simplifying the production process and cost, and increasing the maximum withstand current density and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

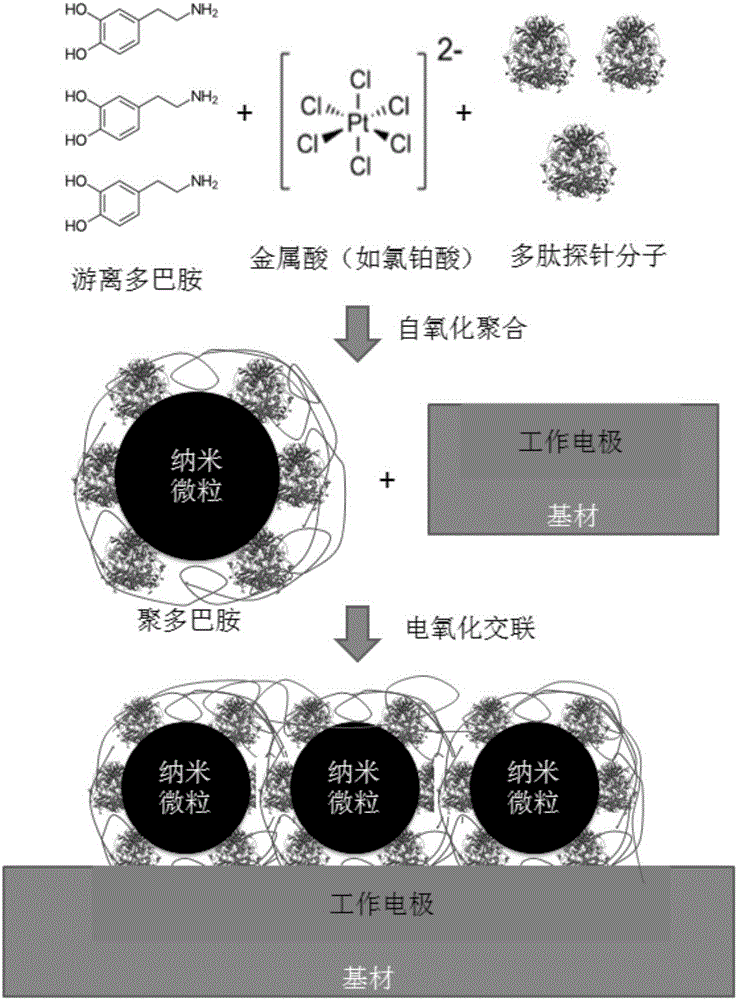

[0033] A method for preparing an electrochemical sensor with a surface-cured polypeptide probe, comprising the steps of:

[0034] Step 1. The electrodes of the electrochemical sensor are prepared on the substrate by conventional electrode processing technology; the conventional electrode processing technology includes metal coating etching or conductive paste screen printing process, and the substrate includes inorganic substrates such as glass, silicon wafers, etc. or organic substrates. The substrate is polyimide, polydimethylsiloxane, etc., wherein the working electrode is carbon, graphene, gold or platinum.

[0035] Step 2, utilize oxidized dopamine to carry out cross-linking nanometer metal particle and polypeptide probe molecule, and be attached on the working electrode, promptly form polydopamine probe layer on the working electrode; Polypeptide probe molecule comprises enzyme protein (such as glucose oxidase, Glucose dehydrogenase, horseradish peroxidase and other oxid...

Embodiment 1

[0043] A method for preparing an electrochemical sensor with a surface-cured polypeptide probe, comprising the steps of:

[0044] Step 1. Prepare the electrode of the electrochemical sensor on the glass substrate by metal coating etching process, wherein the working electrode is platinum.

[0045] Step 2, adding polypeptide probe molecule (glucose oxidase), dopamine molecule and chloroplatinic acid into water, the mass concentration of polypeptide probe molecule is 5mg / mL, the mass concentration of dopamine molecule is 5g / L, the mass concentration of chloroplatinic acid The mass concentration is 5mg / L; the pH is 8, the dissolved oxygen saturation is lower than 1%, and the reaction is carried out at 30°C to generate surface-cured oxidized polydopamine and nano-metal particles of polypeptide probe molecules; The substrate is put into the mixed solution, and the nanometer metal particles are deposited on the surface of the working electrode by electrochemical oxidation reaction. ...

Embodiment 2

[0049] A method for preparing an electrochemical sensor with a surface-cured polypeptide probe, comprising the steps of:

[0050] Step 1, using a conductive paste screen printing process to prepare electrodes for electrochemical sensors on polydimethylsiloxane substrates, wherein the working electrodes are gold.

[0051] Step 2, adding gold nanoparticles, polypeptide probe molecules (hepatitis B virus antibody) and dopamine molecules into water, the size of gold nanoparticles is about 50 nanometers, the mass concentration of gold nanoparticles is 25000ppm, and the mass concentration of polypeptide probe molecules is 4mg / mL, and the mass concentration of dopamine molecules is 6g / L; and the substrate in step 1 is immersed, and the pH is 7, the dissolved oxygen saturation is lower than 1%, 35°C, and the voltage applied on the working electrode is relative to the solution The silver / silver chloride reference electrode in the method performs electrochemical oxidation reaction under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com