A method for efficiently preparing macamide monomer from maca

A technology for macamide and maca, which is applied in the field of efficient preparation of macamide monomers, can solve the problems of difficulty in ensuring high purity of macamide monomers, low recovery rate of macamide, and unpreparedness, etc. The effect of short cycle, large preparation and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

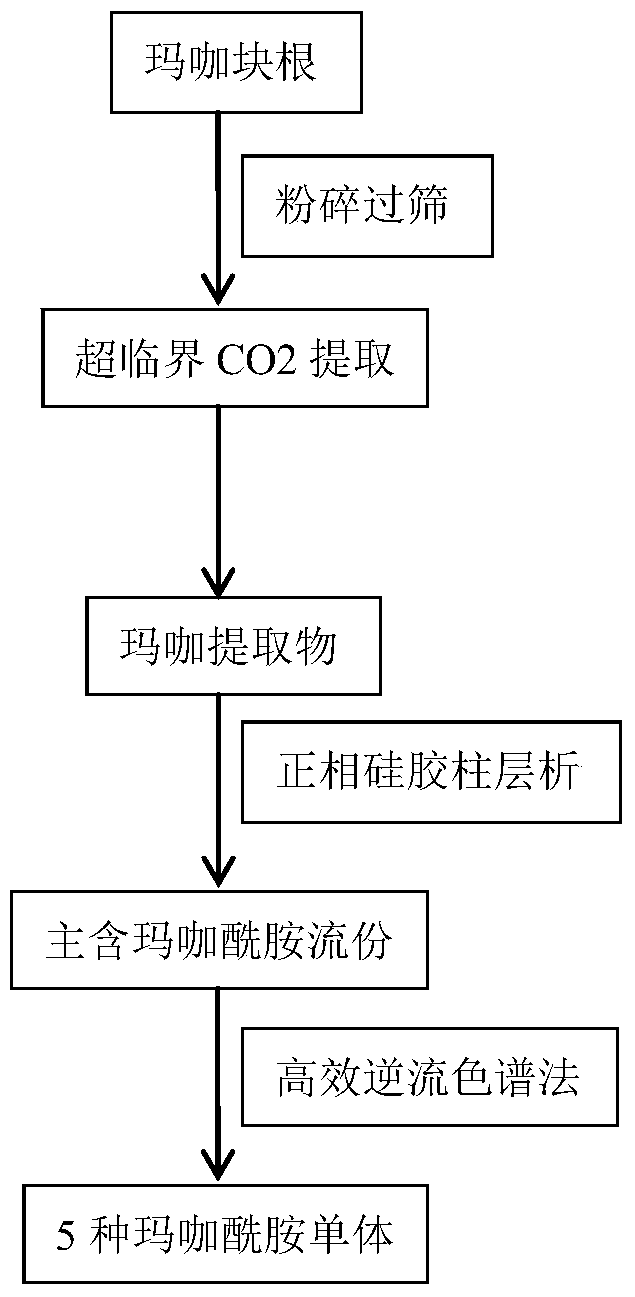

Method used

Image

Examples

Embodiment 1

[0032] Get 5897.3g of maca root, crush it through a 20-mesh sieve, and put it into supercritical CO 2 In the extraction kettle, at a temperature of 45°C and an extraction pressure of 30MPa, CO 2 The flow rate is 200L / h, the extraction is 2h, and 22g of maca extract is obtained.

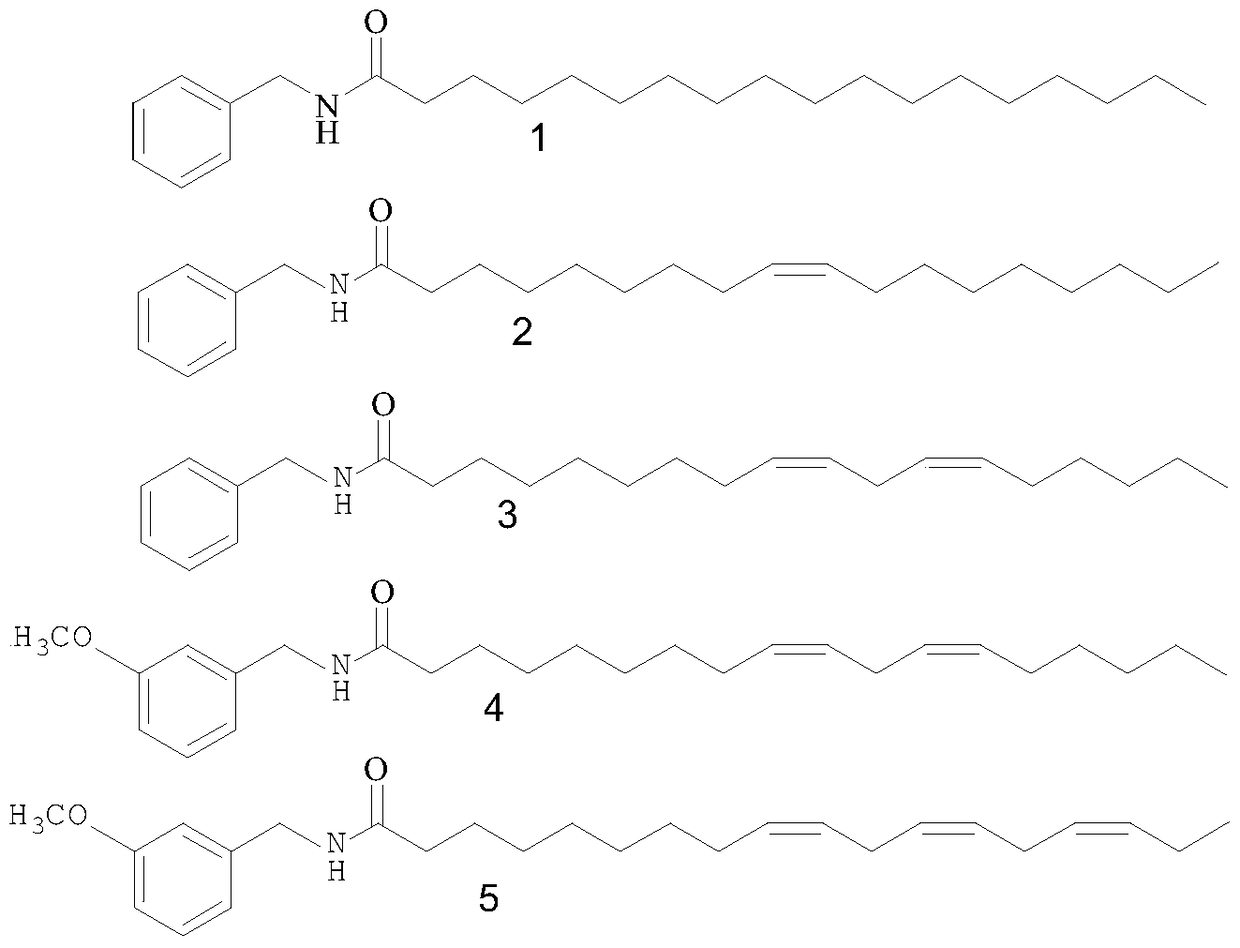

[0033] The maca extract was separated by normal phase silica gel column chromatography by dry mixing and wet column packing, gradient elution was carried out with n-hexane-ethyl acetate, and the main fraction containing macamide was collected for later use. Use high-efficiency countercurrent chromatography equipment to separate the main macamide-containing fraction, mix n-hexane-ethyl acetate-methanol-water in a volume ratio of 6:1:5:1, and separate after static layering. The above phase is The stationary phase, the lower phase is the mobile phase, the single injection volume is 1.01g, the injection concentration is 50mg / ml (dissolved in the upper phase), the flow rate of the mobile phase is 10ml / min...

Embodiment 2

[0037] Get 6000g of maca root, crush it through a 20-mesh sieve, and put it into supercritical CO 2 In the extraction kettle, at a temperature of 50°C and an extraction pressure of 28MPa, CO 2 Flow rate is 300L / h, extraction is 2h, obtains Maca extract 23g.

[0038] The maca extract was mixed by dry method and packed by wet method for normal phase silica gel column chromatography, and gradient elution was carried out by n-hexane-acetone, and the fraction mainly containing macamide was collected for later use. Use high-efficiency countercurrent chromatography equipment to separate the main macamide-containing fraction, mix n-hexane-ethyl acetate-methanol-water in a volume ratio of 7:2:5:1, and separate after standing and layering. The above phase is The stationary phase, the lower phase is the mobile phase, the single injection volume is 2.0g, the injection concentration is 70mg / ml (dissolved in the upper phase), the flow rate of the mobile phase is 10ml / min, the rotation spee...

Embodiment 3

[0042] Take 6150g of maca root, crush it through a 10-mesh sieve, and put it into CO 2 In a supercritical extraction kettle, with a temperature of 48°C and an extraction pressure of 29MPa, CO 2 Flow rate is 250L / h, extract 3h, obtain maca extract 23.5g.

[0043] The maca extract was mixed by dry method and packed by wet method for normal phase silica gel column chromatography, and petroleum ether-ethyl acetate was used for gradient elution, and the main fraction containing macamide was collected for later use. Use high-efficiency countercurrent chromatography equipment to separate the main macamide-containing fraction, mix n-hexane-ethyl acetate-methanol-water in a volume ratio of 8:2:5:1, and separate after standing and layering. The above phase is The stationary phase, the lower phase is the mobile phase, the single injection volume is 5.0g, the injection concentration is 100mg / ml (dissolved in the upper phase), the flow rate of the mobile phase is 10ml / min, the rotation sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com