The Extraction Method of Ginseng Palmar Polysaccharide

An extraction method and technology of ginseng polysaccharides, which are applied in the field of extraction of ginseng polysaccharides, can solve the problems of poor product thermal stability, long extraction time period, and difficulties in industrial application, and achieve good activity preservation, short extraction time, and improved dissolution efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

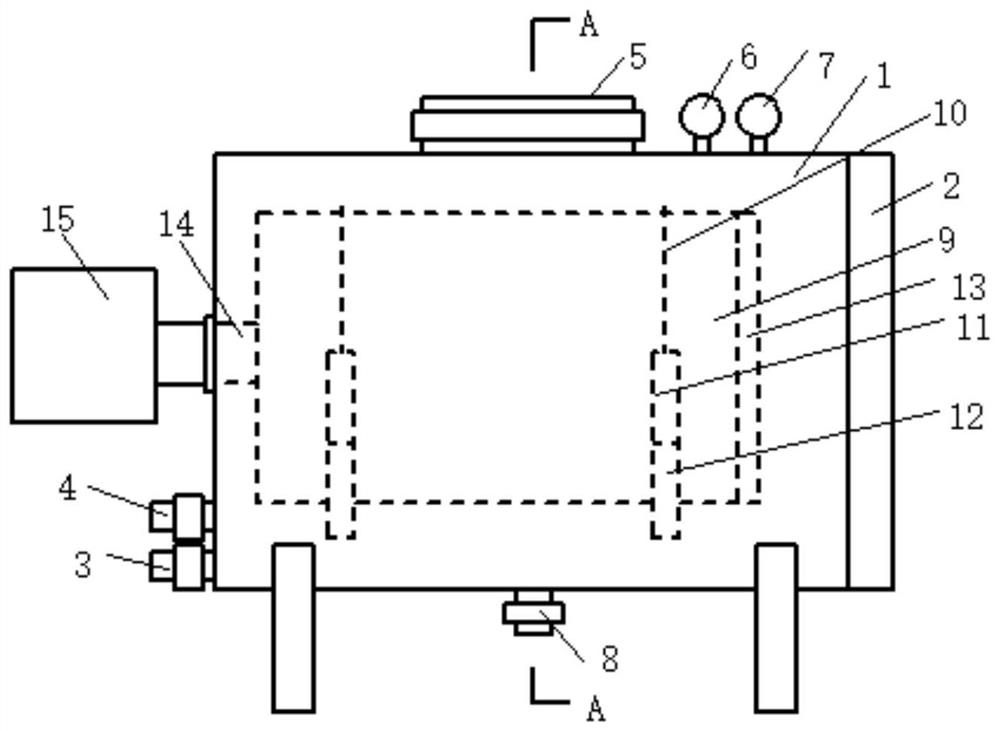

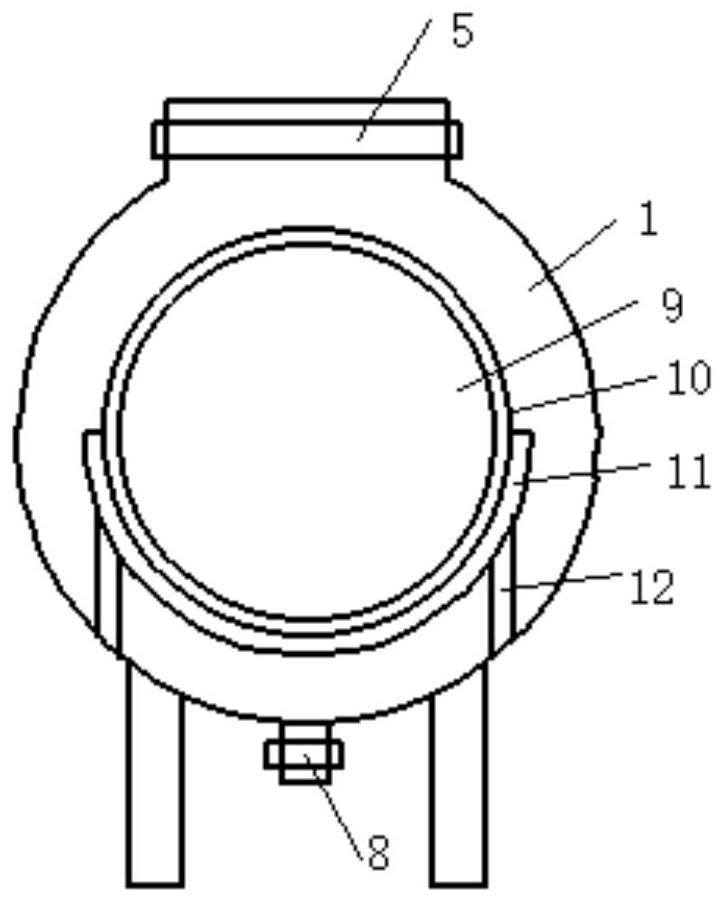

[0031] The extracting method of palm ginseng polysaccharide comprises the following steps:

[0032] S1, take palm ginseng, after coarse powder, pass through a 20-mesh sieve to obtain palm ginseng powder;

[0033] S2. Add 4 times the weight of sodium bicarbonate and sodium sulfite mixed solution to the palm ginseng powder, soak for 1 hour at room temperature, and centrifugally filter to make the water content of the filter cake 45-50%, to obtain the first filter cake;

[0034] S3. Dispersing the first filter cake, placing it in a steam explosion tank, and performing superheated steam spray explosion treatment in a moving state to obtain steam explosion materials;

[0035] S4. Add water of 20 times the weight of the palm ginseng powder to the steam explosion, extract at room temperature for 40 minutes, and centrifugally filter to make the water content of the filter cake less than 20%, and take the filtrate to obtain water Extract;

[0036] S5. Concentrating the water extract ...

Embodiment 2

[0040] The extracting method of palm ginseng polysaccharide comprises the following steps:

[0041] S1, take palm ginseng, after coarse powder, pass through a 20-mesh sieve to obtain palm ginseng powder;

[0042] S2. Add 4.5 times the weight of sodium bicarbonate and sodium sulfite mixed solution to the palm ginseng powder, soak for 1.5 hours at room temperature, and centrifugally filter to make the water content of the filter cake 45-50%, to obtain the first filter cake;

[0043] S3. Dispersing the first filter cake, placing it in a steam explosion tank, and performing superheated steam spray explosion treatment in a moving state to obtain steam explosion materials;

[0044] S4. Add 22 times the weight of the ginseng powder to the steam explosive, extract at room temperature for 45 minutes, and centrifugally filter to make the water content of the filter cake less than 20%. Take the filtrate to obtain water Extract;

[0045] S5. Concentrating the water extract under reduced...

Embodiment 3

[0048] The extracting method of palm ginseng polysaccharide comprises the following steps:

[0049] S1, take palm ginseng, after coarse powder, pass through a 20-mesh sieve to obtain palm ginseng powder;

[0050] S2. Add 5 times the weight of the mixed solution of sodium bicarbonate and sodium sulfite to the ginseng powder, soak for 1.5 hours at room temperature, and centrifugally filter to make the water content of the filter cake 45-50%, to obtain the first filter cake;

[0051] S3. Dispersing the first filter cake, placing it in a steam explosion tank, and performing superheated steam spray explosion treatment in a moving state to obtain steam explosion materials;

[0052] S4. Add water of 25 times the weight of the palm ginseng powder to the steam explosion, extract at room temperature for 50 minutes, and centrifugally filter to make the water content of the filter cake less than 20%, and take the filtrate to obtain water Extract;

[0053] S5. Concentrating the water ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com