A kind of iron-based amorphous alloy composite material

A technology of iron-based amorphous alloys and composite materials, applied in metal processing equipment, transportation and packaging, etc., can solve the problem of iron-based amorphous alloys lacking room temperature plasticity, narrow temperature range for two crystallizations, and materials prone to brittle fractures, etc. problems, to achieve excellent high plasticity and soft magnetic properties, optimization of soft magnetic properties, and the effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

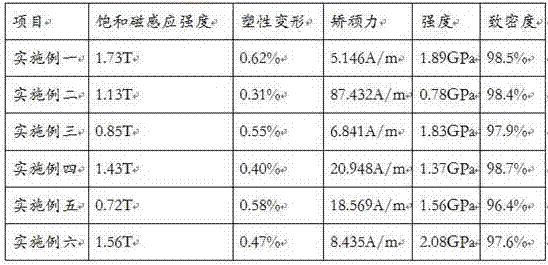

Examples

Embodiment 1

[0020] An iron-based amorphous alloy composite material, the composition of the iron-based amorphous alloy composite material is: Fe 76 Al 4 Ga 2 Y 3 In 1.86 co 8 B 4 Si 1.14 , its preparation method comprises the following steps:

[0021] Step 1, raw material preparation, respectively take Fe powder with a purity of 99.99% and a particle size of 40 μm, Al powder with a purity of 99.5% and a particle size of 80 μm, and Ga powder with a purity of 99% and a particle size of 80 μm with a purity of 99% and a particle size of Y powder of 75 μm with a purity of 97.5%, In powder with a particle size of 120 μm, Co powder with a purity of 98.5% and a particle size of 75 μm, a purity of 99.9%, B powder with a particle size of 15 μm and B powder with a purity of 99.9% and a particle size of 75 μm The silicon powder is made into the nominal alloy composition according to the atomic percentage, and then placed in a planetary ball milling tank together with hard alloy balls with a di...

Embodiment 2

[0025] An iron-based amorphous alloy composite material, the composition of the iron-based amorphous alloy composite material is: Fe 72 Al 5 Ga 2 V 3 co 10 B 8 , its preparation method comprises the following steps:

[0026] Step 1, raw material preparation, respectively take the Fe powder with a purity of 99.99% and a particle size of 40 μm, the Al powder with a purity of 99.5% and a particle size of 80 μm, the Ga powder with a purity of 99% and a particle size of 80 μm, and a purity of 99.5% with a particle size of It is 75μm V powder with a purity of 98.5%, Co powder with a particle size of 75μm, and B powder with a purity of 99.9% and a particle size of 15μm. Put it in a planetary ball milling tank for ball milling. Before the ball milling, the ball milling tank should be vacuumized. When the vacuum degree in the ball milling tank reaches 0.5Pa, fill the ball milling tank with 1MPa of argon gas. During the ball milling, the ball mill speed is 300r / min. The ball powde...

Embodiment 3

[0030] An iron-based amorphous alloy composite material, the composition of the iron-based amorphous alloy composite material is: Fe 70 Al 3 Ga 2 Y 1.63 V 1.37 In 1 co 10 B 8 Si 3 , its preparation method comprises the following steps:

[0031] Step 1, raw material preparation, respectively take Fe powder with a purity of 99.99% and a particle size of 40 μm, Al powder with a purity of 99.5% and a particle size of 80 μm, and Ga powder with a purity of 99% and a particle size of 80 μm with a purity of 99% and a particle size of Y powder with a purity of 75 μm, a purity of 99.5%, a V powder with a particle size of 75 μm, a purity of 97.5%, an In powder with a particle size of 120 μm, a purity of 98.5%, a Co powder with a particle size of 75 μm, a purity of 99.9%, and a particle size of 15 μm The B powder and the Si powder with a purity of 99.9% and a particle size of 75 μm are formulated into a nominal alloy composition according to atomic percentage, and then placed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com