Ultralow-molecular weight intercalation inhibitor and preparation method thereof

A molecular weight and inhibitor technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as underground environmental pollution, high toxicity of alkyl diamines, and reduced inhibitory performance, so as to reduce the instability of the well wall, The synthesis process is simple and the effect of improving the temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

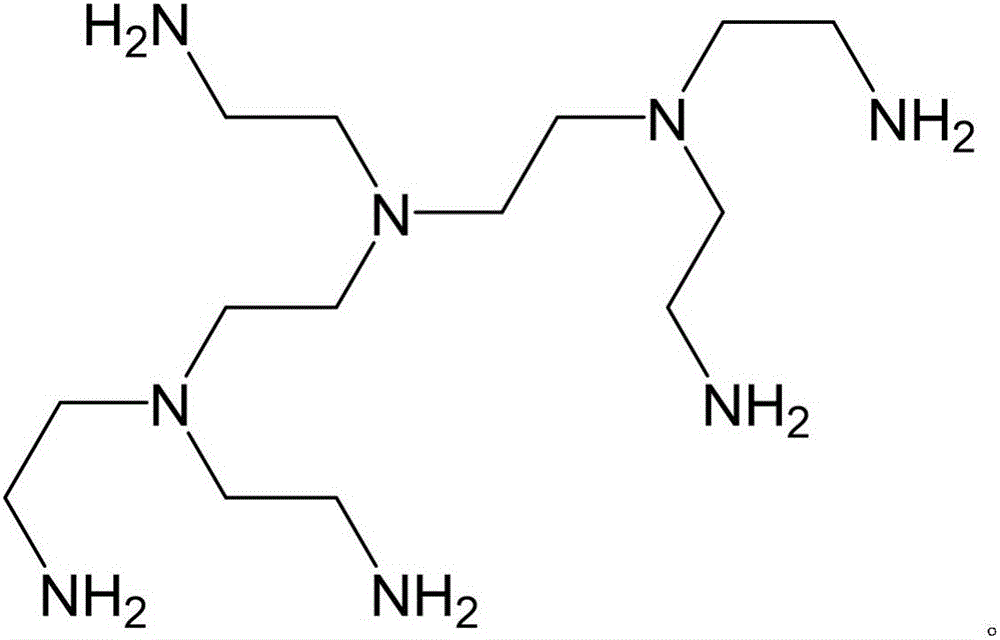

Image

Examples

Embodiment 1

[0036] (one),

[0037] 1. Add 0.1mol of nitrilotriacetic acid into a 500ml single-necked flask, add 250ml of absolute ethanol, add 5ml of concentrated sulfuric acid, and react at 75°C for 3h.

[0038] 2. After cooling to room temperature, concentrate under reduced pressure. Add 100ml of dichloromethane, add 10% sodium hydroxide solution dropwise at 0°C until the pH test paper is alkaline, separate the organic layer, dry over anhydrous magnesium sulfate, filter, and distill to obtain ethyl nitrilotriacetate.

[0039] 3. Dissolve 0.05mol of ethyl nitrilotriacetate in 100ml of ammonia water, and vigorously stir for 24 hours in a water bath at 50°C. The solvent was distilled off under reduced pressure to obtain nitrilotriacetic acid triamide, which was dried in vacuo.

[0040] 4. Dissolve 0.05mol nitrilotriacetic acid triamide in dimethyl sulfoxide, add 0.05mol sodium borohydride, dropwise add 0.1mol boron trifluoride ether, or add 0.1mol lithium aluminum hydride at 5°C, and hea...

Embodiment 2

[0054] (one),

[0055] 1. Add 0.1mol of ethylenediaminetetraacetic acid into a 500ml single-necked flask, add 250ml of absolute ethanol, add 5ml of concentrated sulfuric acid, and react at 75°C for 3h.

[0056] 2. After cooling to room temperature, concentrate under reduced pressure. Add 100ml of dichloromethane, add 10% sodium hydroxide solution dropwise at 0°C until the pH test paper is alkaline, separate the organic layer, dry over anhydrous magnesium sulfate, filter, and distill to obtain ethylenediaminetetraacetic acid tetra ethyl ester.

[0057] 3. Dissolve 0.05 mol of tetraethyl ethylenediamine tetraacetate in 50 ml of organic solvent dimethyl sulfoxide, add 5 equivalents of ammonia methanol, add 1% sodium methoxide, and vigorously stir in a water bath at 50°C for 24 hours. The solvent was distilled off under reduced pressure to obtain ethylenediaminetetraacetic acid tetraamide, which was dried in vacuo.

[0058] 4. Dissolve 0.05mol of ethylenediaminetetraacetic acid...

Embodiment 3

[0070] (one),

[0071] 1. Add 0.1mol of diethylenetriaminepentaacetic acid into a 500ml single-necked flask, add 250ml of absolute ethanol, add 5ml of concentrated sulfuric acid, and react at 15°C for 3h.

[0072] 2. After cooling to room temperature, concentrate under reduced pressure. Add 100ml of dichloromethane, add 10% sodium hydroxide solution dropwise at 0°C until the pH test paper is alkaline, separate the organic layer, dry over anhydrous magnesium sulfate, filter, and distill to obtain diethylenetriaminepentaacetic acid pentaethyl ester.

[0073] 3. Dissolve 0.05 mol of pentaethyl diethylenetriaminepentaacetate in 50 ml of organic solvent dimethyl sulfoxide, add 5 equivalents of ammonia methanol, add 1% sodium methoxide, and vigorously stir in a water bath at 50°C for 24 hours. The solvent was distilled off under reduced pressure to obtain diethylenetriaminepentaacetic acid pentamide, which was dried in vacuum.

[0074] 4. Dissolve 0.05mol of diethylenetriaminepen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com