A kind of ultra-high gradient zinc oxide varistor and its preparation method

A varistor and zinc oxide technology, applied in varistors, varistor cores, etc., to achieve the effects of strong combined wave resistance, good aging performance, and high energy tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

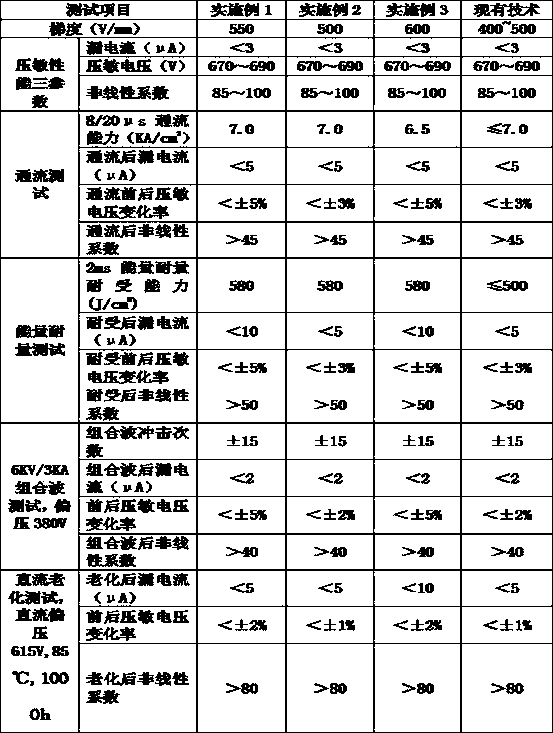

Examples

Embodiment 1

[0024] An ultra-high gradient zinc oxide varistor and a preparation method thereof are carried out according to the following steps:

[0025] 1. First weigh the analytically pure raw material Co with a purity ≥99% 3 o 4 461.2727 grams, Sb 2 o 3 951.6044 g, MnCO 3 186.3170 grams, Bi 2 o 3 472.0446 grams, Ni 2 o 3 193.6075 grams, ZrO 2 17.7816 grams, SiO 2 20.2882 grams, Y 2 o 3 162.6731 g, SnO 2 33.9285 grams into the ball mill jar, then add 8 kilograms of zirconium balls, 2.5 kilograms of deionized water and 49 grams of dispersant, wet ball mill and mix for 4 hours, and configure it as an ultra-high gradient varistor additive;

[0026] 2. Weigh 22.9996 grams of Ba(CH 3 COO) 2 , 4.2225 grams of Al (NO 3 ) 3 9H 2 O, 5.7363 g AgNO 3 and 2.7839 g H 3 BO 3 , add 200 grams of deionized water to dissolve it completely, and configure it as an additive solution; weigh 17464.7399 grams of analytically pure raw material ZnO with a purity ≥ 99%, put it into a st...

Embodiment 2

[0035] An ultra-high gradient zinc oxide varistor and a preparation method thereof are carried out according to the following steps:

[0036] 1. First weigh the analytically pure raw material Co with a purity ≥99% 3 o 4 499.5488 grams, Sb 2 o 3 1138.0000 g, MnCO 3 217.9489 grams, Bi 2 o 3 467.7338 grams, Ni 2 o 3 184.4610 g, ZrO 2 13.7436 g, SiO 2 20.1029 grams, Y 2 o 3 176.2989 grams, SnO 2 Put 26.8949 grams into the ball mill jar, then add 9 kilograms of zirconium balls, 3 kilograms of deionized water and 50 grams of dispersant, wet ball mill and mix for 6 hours, and configure it as an ultra-high gradient varistor additive;

[0037] 2. Weigh 28.4870 grams of Ba(CH 3 COO) 2 , 4.1840 g Al(NO 3 ) 3 9H 2 O, 3.7893 g AgNO 3 and 3.4481 g H 3 BO 3 , add 200 grams of deionized water to dissolve it completely, and configure it as an additive solution; weigh 17215.3588 grams of analytically pure raw material ZnO with a purity ≥ 99%, put it into a stirring ...

Embodiment 3

[0046] An ultra-high gradient zinc oxide varistor and a preparation method thereof are carried out according to the following steps:

[0047] 1. First weigh the analytically pure raw material Co with a purity ≥99%3 o 4 509.3723 grams, Sb 2 o 3 1116.4758 g, MnCO 3 217.5562 grams, Bi 2 o 3 539.5184 grams, Ni 2 o 3 158.3506 g, ZrO 2 27.4376 g, SiO 2 16.0534 grams, Y 2 o 3 150.8410 g, SnO 2 Put 33.5581 grams into the ball mill jar, then add 9 kilograms of zirconium balls, 3 kilograms of deionized water and 49 grams of dispersant, wet ball mill and mix for 8 hours, and configure it as an ultra-high gradient varistor additive;

[0048] 2. Weigh 8.5307 grams of Ba(CH 3 COO) 2 , 16.7058 grams of Al (NO 3 ) 3 9H 2 O, 18.9122 g AgNO 3 and 6.8837 g H 3 BO 3 , add 200 grams of deionized water to dissolve it completely, and configure it as an additive solution; weigh 17179.8043 grams of analytically pure raw material ZnO with a purity ≥ 99% and put it into a sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com