Ultraviolet-resistant melamino-formaldehyde resin fiber and preparation method thereof

A melamine and formaldehyde resin technology, applied in the chemical characteristics of fibers, rayon manufacturing, single-component synthetic polymer rayon, etc., can solve the problem of resin fibers not being UV resistant, and achieve the effect of lasting UV resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

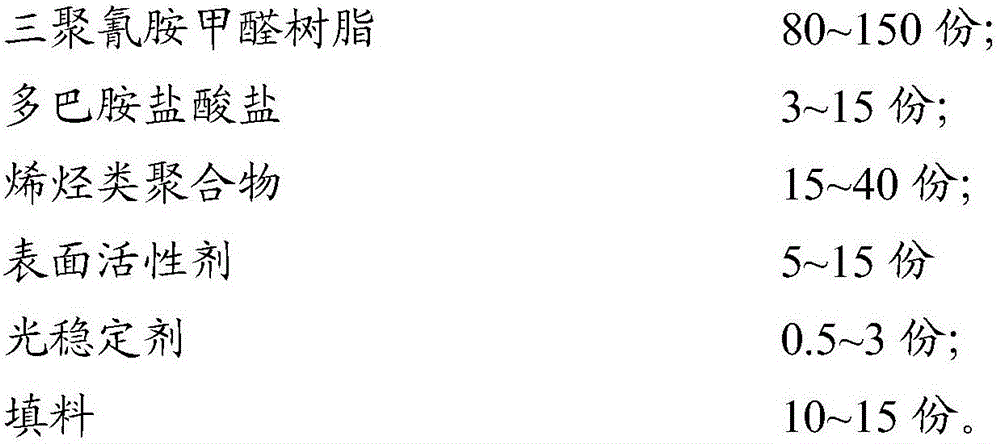

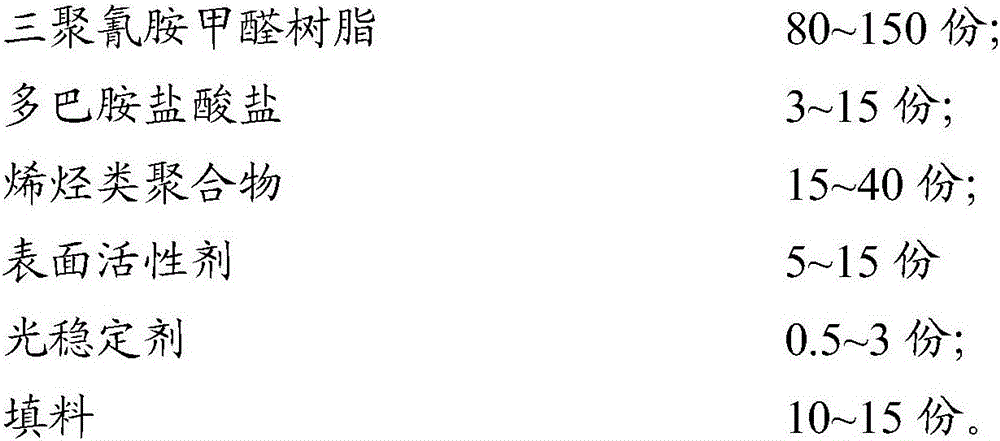

[0033] The present invention also provides a kind of preparation method of anti-ultraviolet melamine formaldehyde resin fiber, comprises the following steps:

[0034] Disperse the melamine formaldehyde resin, filler, surfactant and light stabilizer in water, add dopamine hydrochloride after the dispersion is uniform; keep it in the dark for 18-36 hours, then add olefin polymer, seal and stir at 40-50°C React for 8-15 hours to obtain the melamine-formaldehyde resin spinning stock solution;

[0035]The melamine-formaldehyde resin spinning stock solution is extruded through a spinneret hole, and the extruded product enters a coagulation bath through an air layer to be solidified, and after washing and drying, the anti-ultraviolet melamine-formaldehyde resin fiber is obtained.

[0036] In the present invention, dopamine hydrochloride is added to the solution mixed with melamine formaldehyde resin, filler and light stabilizer, and kept away from light for 18-36 hours, so that the m...

Embodiment 1

[0051] Disperse 80g melamine formaldehyde resin, 8g sodium dodecylbenzene sulfonate, 15g titanium dioxide and 1.5g 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole in 40g water, stir well Add 3g of dopamine hydrochloride; after standing in the dark for 18h, add 15g of polybutene, 5g of NaHSO 4 , Sealed and stirred at 40° C. for 8 hours to obtain a melamine-formaldehyde resin spinning stock solution.

[0052] The above-mentioned melamine-formaldehyde resin spinning stock solution is formed by dry spraying and wet spinning, and the spinning slurry at room temperature is accurately metered with a metering pump, and then extruded from the spinneret hole, wherein the spinneret has 200 holes, and the hole diameter is 0.2mm , the spray ratio is 1.5 times, and the spinning speed is 100m / min; the extrudate obtained by extruding through the spinneret hole passes through the air layer with a height of 10mm into the dimethyl sulfoxide and water with a volume ratio of 1:4 In a coagulation bat...

Embodiment 2

[0054] Disperse 150g of melamine formaldehyde resin, 10g of sodium lauryl sulfate, 15g of calcium carbonate and 2g of 2-(2'-hydroxy-3',5'-α,α-dimethylbenzyl)benzotriazole in 90g In water, stir well and add 15g of dopamine hydrochloride; after standing in the dark for 36h, add 40g of binary ethylene propylene rubber, 15g of NH 4 Cl, sealed and stirred at 50° C. for 15 h to obtain a melamine-formaldehyde resin spinning stock solution.

[0055] The above-mentioned melamine-formaldehyde resin spinning stock solution is spun and formed by wet spinning technology, and the spinning slurry at room temperature is accurately measured by a metering pump, and then extruded from the spinneret hole, wherein the spinneret has 30 holes, and the hole diameter is 0.12. mm, the spray ratio is 2.0 times, and the spinning speed is 30m / min; the extrudate obtained by extruding through the spinneret hole enters the coagulation of N,N-dimethylformamide and water with a volume ratio of 1:6 bath, washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com