Anti-ultraviolet DTY filament and production process thereof

A technology of anti-ultraviolet and production technology, applied in the textile field, can solve the problems of fabrics losing anti-ultraviolet and poor washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

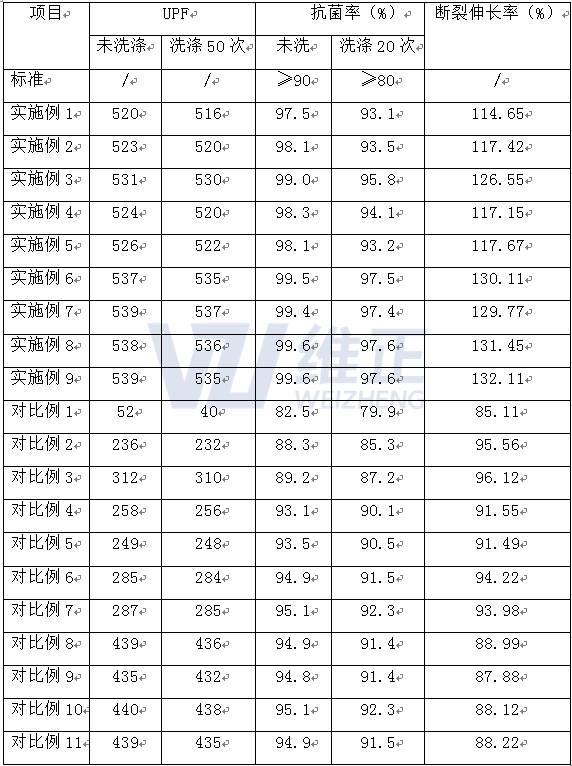

Examples

preparation example 1

[0051] The preparation method of Uralia sativa fiber: immerse 0.3g of Urassica sativa in 6g of hydrogen peroxide, 0.8g of sodium hydroxide and 0.8g of penetrant JFC-2, react at a temperature of 62°C for 1.2h, then take out the Urassica sativa and wash it and dried at a temperature of 58°C to a constant weight, and then soaked the dried Ulagrass in 9g polyethylene glycol-2000, 2.3g sodium hydroxide, 1.3g Na 2 CO 3 , 1.3gNa 2 SO 3 In the mixed solution, react at a temperature of 85°C for 1.8h, then wash, and dry at a temperature of 55°C to constant weight to obtain ulagrass fiber.

preparation example 2

[0053] The preparation method of Uralia sativa fiber: immerse 0.5g of Urassica sativa in the mixture of 7g of hydrogen peroxide, 1.0g of sodium hydroxide and 1.0g of penetrant JFC-2, react at a temperature of 63.5°C for 1.35h, then take out the Urassia sageum and wash it and dried at a temperature of 59°C to a constant weight, and then soaked the dried Ulagrass in 9.5g polyethylene glycol-2000, 2.5g sodium hydroxide, 1.5g Na 2 CO 3 , 1.5gNa 2 SO 3 In the mixed solution, react at a temperature of 87.5°C for 1.9h, then wash, and dry at a temperature of 57.5°C to constant weight to obtain ulagrass fiber.

preparation example 3

[0055] The preparation method of Uralia sativa fiber: immerse 0.7g of Urassica sativa in 8g of hydrogen peroxide, 1.2g of sodium hydroxide and 1.2g of penetrant JFC-2, react at a temperature of 65°C for 1.5h, then take out the Urassia sativa and wash it and dried at a temperature of 60°C to a constant weight, and then soaked the dried Ulagrass in 10g polyethylene glycol-2000, 2.7g sodium hydroxide, 1.7g Na 2 CO 3 , 1.7gNa 2 SO 3 In the mixed solution, react at 90°C for 2 hours, then wash, and dry at 60°C to constant weight to obtain ulagrass fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com