A kind of anti-ultraviolet dty yarn and its production process

A technology of anti-ultraviolet and production technology, applied in the textile field, can solve the problems of poor washing fastness and loss of anti-ultraviolet of fabrics, achieve high mechanical properties and stability, long-term anti-ultraviolet ability, and improve the effect of anti-ultraviolet ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

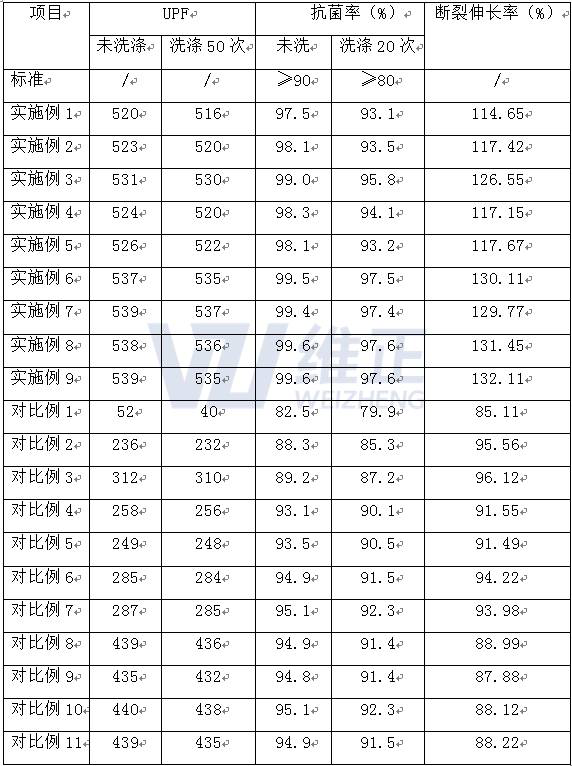

Examples

preparation example 1

[0051] Preparation method of urax fiber: immerse 0.3g of urax in a mixture of 6g of hydrogen peroxide, 0.8g of sodium hydroxide and 0.8g of penetrant JFC-2, react at 62°C for 1.2h, then take out urax and wash And dried to constant weight at a temperature of 58 ° C, and then immersed in 9g polyethylene glycol-2000, 2.3g sodium hydroxide, 1.3g Na 2 CO 3 , 1.3gNa 2 SO 3 In the mixed solution of , at a temperature of 85 °C, react for 1.8 h, then wash, and dry at a temperature of 55 °C to a constant weight to obtain uranium fiber.

preparation example 2

[0053] Preparation method of urax fiber: immerse 0.5g of urax in a mixture of 7g of hydrogen peroxide, 1.0g of sodium hydroxide and 1.0g of penetrant JFC-2, react for 1.35h at a temperature of 63.5°C, and then take out the urax and wash it And dried at a temperature of 59 ° C to constant weight, and then immersed in 9.5g polyethylene glycol-2000, 2.5g sodium hydroxide, 1.5g Na 2 CO 3 , 1.5g Na 2 SO 3 In the mixed solution of , at a temperature of 87.5 ° C, react for 1.9 h, then wash, and dry at a temperature of 57.5 ° C to constant weight to obtain uran grass fiber.

preparation example 3

[0055] Preparation method of urax fiber: immerse 0.7g of urax in a mixture of 8g of hydrogen peroxide, 1.2g of sodium hydroxide and 1.2g of penetrant JFC-2, react at 65°C for 1.5h, then take out urax and wash And dried at a temperature of 60 ° C to constant weight, and then immersed in 10g polyethylene glycol-2000, 2.7g sodium hydroxide, 1.7g Na 2 CO 3 , 1.7gNa 2 SO 3 In the mixed solution of , at a temperature of 90 ° C, react for 2 h, then wash, and dry at a temperature of 60 ° C to constant weight to obtain urax fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com