A kind of preparation technology of white gray cloth

A preparation process and white gray cloth technology, which is applied in rayon manufacturing, textile, single-component polyester rayon, etc., can solve the problem of limited anti-ultraviolet effect, disappearance of anti-ultraviolet effect and weakened anti-ultraviolet performance of anti-ultraviolet cotton fabrics, etc. problem, to achieve long-term anti-ultraviolet effect

Active Publication Date: 2022-06-10

江苏三盛纺织有限公司

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the anti-ultraviolet effect of the anti-ultraviolet cotton fabric obtained by physical attachment is limited, and the anti-ultraviolet performance of the fabric will gradually weaken after washing, and the anti-ultraviolet effect will disappear after repeated washing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

[0044] The preparation of the white grey cloth: weaving with the obtained anti-ultraviolet modified polyester fiber to obtain a white grey cloth.

Embodiment 2

[0050] The preparation of the white grey cloth: weaving with the obtained anti-ultraviolet modified polyester fiber to obtain a white grey cloth.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

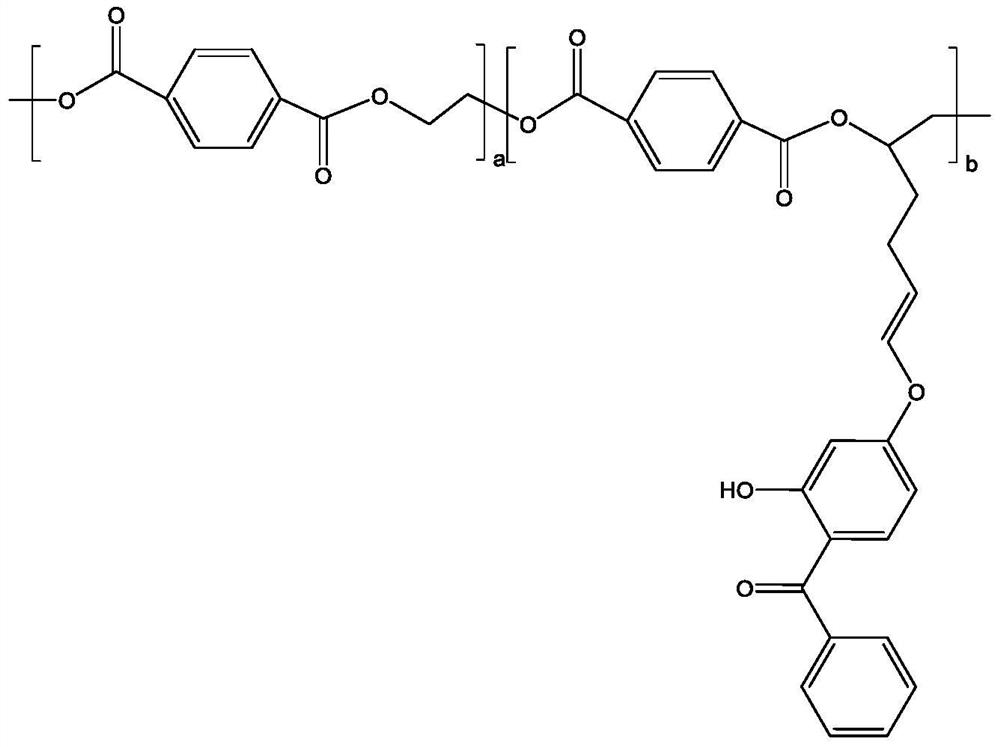

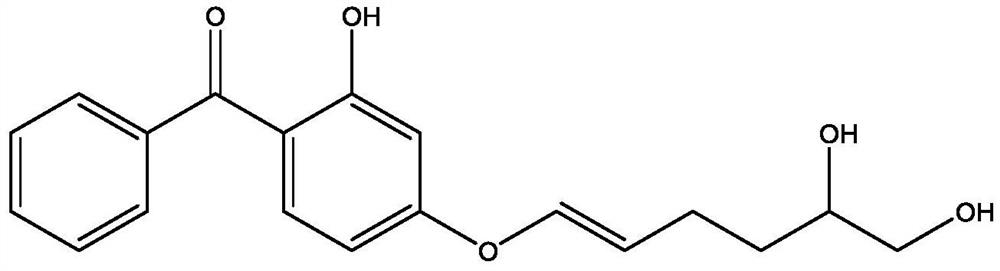

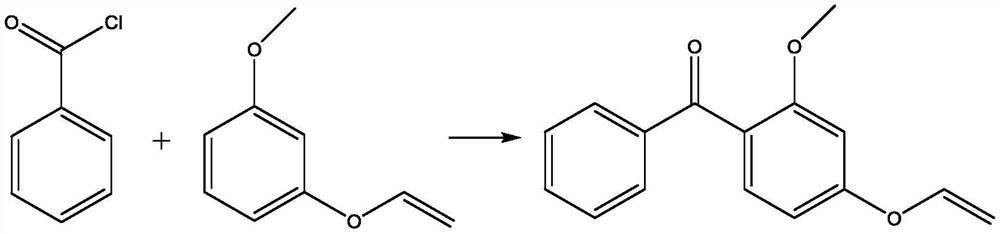

The application belongs to the technical field of fabrics, and specifically relates to a preparation process of white gray cloth, comprising the following steps: weaving polyester fibers to obtain white gray cloth; the polyester fibers are ultraviolet-resistant modified polyester fibers. The preparation process of the white gray cloth of the present application uses anti-ultraviolet modified polyester fiber to weave to obtain the white gray cloth, and the white gray cloth can be dyed and other post-processing according to the specific fabric requirements. Since the anti-ultraviolet modification is directly carried out on the polyester fiber, Rather than the anti-ultraviolet modification of the physical attachment method, the anti-ultraviolet effect of the prepared white gray cloth will not be attenuated or even disappeared due to external forces such as washing, and the prepared white gray cloth has a long-term anti-ultraviolet effect.

Description

A kind of preparation technology of white grey cloth technical field The application belongs to technical field of cloth, be specifically related to a kind of preparation technology of white grey cloth. Background technique [0002] The white grey fabric is a grey fabric woven by undyed yarns. Grey fabrics include pure fabrics, blended fabrics, blended and woven fabrics fabrics, interwoven fabrics. After dyeing and post-processing, white grey cloth can be used in fields with different needs. With the development of science and technology and economy, people's self-protection awareness is strengthened, and the requirements for clothing fabrics are also increasing. The higher the value, the more UV-resistant fabrics are used in the apparel field. The current common anti-ultraviolet treatment methods are The anti-ultraviolet solution is physically attached to the surface of the fabric, although this method can obtain a certain anti-ultraviolet effect. However, after ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D03D15/283D03D15/50D01F6/92D01F1/10C08G63/676

CPCD03D15/283D03D15/50D01F6/92D01F1/103C08G63/676D10B2331/04D10B2401/22D10B2401/13

Inventor 张文博

Owner 江苏三盛纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com