A method for desulfurization of coal before combustion with ultrasonic equipment combined with composite extraction liquid

A pre-combustion desulfurization and extraction technology, which is applied in the field of coal desulfurization, can solve problems such as coal quality changes, complex processes, and calorific value reduction, and achieve the effects of accelerating reaction speed, improving reaction conditions, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

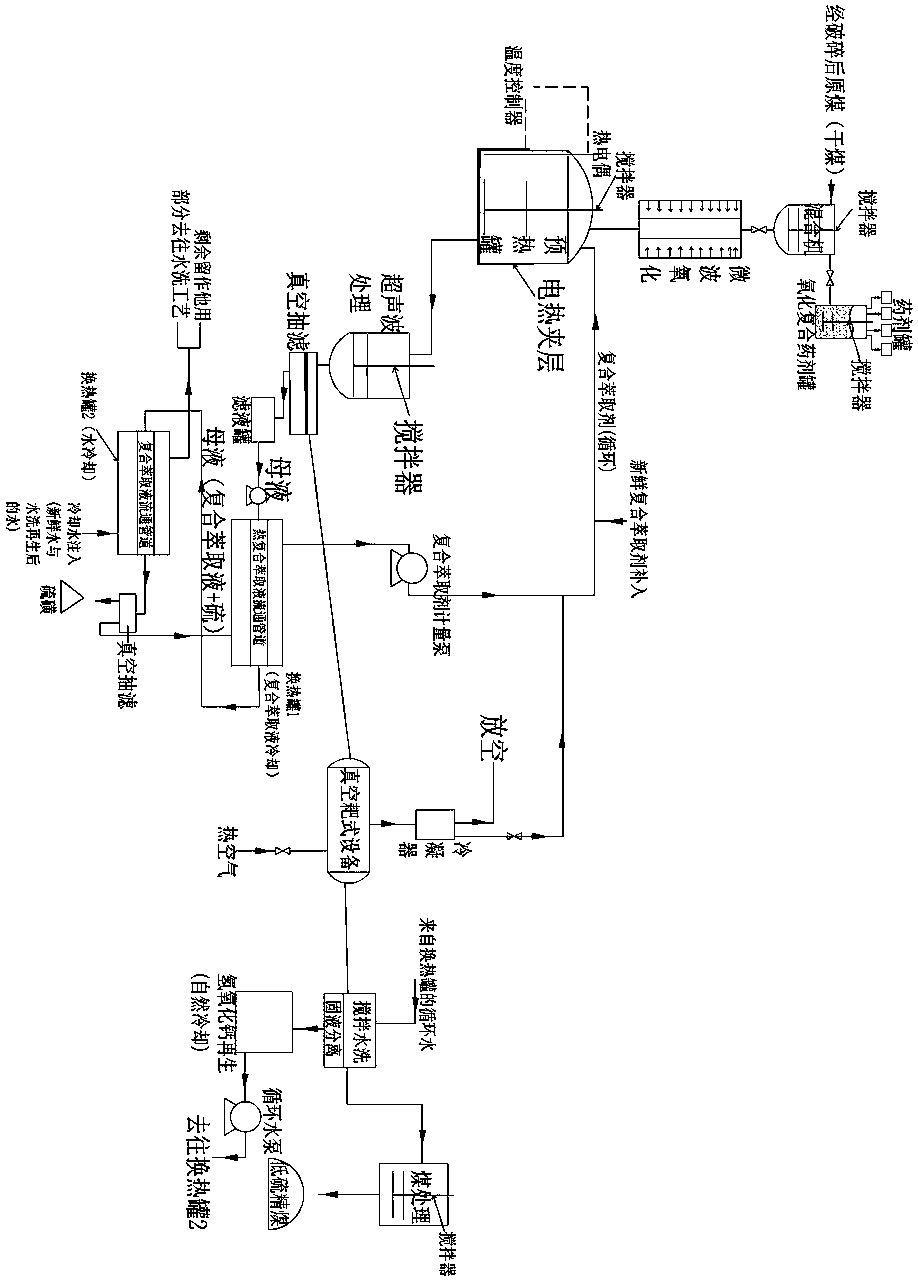

Image

Examples

Embodiment 1

[0052] The method for desulfurizing coal before combustion of the ultrasonic equipment combined with the composite extract comprises the following steps:

[0053] (1) Microwave irradiation

[0054] The raw coal is mixed with the composite oxidant at a weight ratio of 10:1, and then enters the WXD tunnel type high-power tube microwave equipment for microwave irradiation. The residence time in the microwave device enters the subsequent chemical desulfurization process after 10 minutes of microwave irradiation;

[0055] The composite oxidant is one or more of hydrogen peroxide, 8.4% dilute nitric acid, potassium dichromate, ferric acid, tert-butanol peroxide, triisopropanolamine, and an oxidation catalyst.

[0056] (2) Preheating before ultrasound

[0057] Put the composite extract and raw coal into the preheating tank at the same time according to the weight ratio of 10:1, and the raw coal and the composite extract in the preheating tank are fully stirred to obtain coal slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com