Chelate type metal ion flotation reagent, and preparation method and application method thereof

A technology for metal ions and flotation reagents, applied in chemical instruments and methods, flotation water/sewage treatment, other chemical processes, etc., to achieve the effects of being beneficial to metal resource recovery, low consumption of reagents, and beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

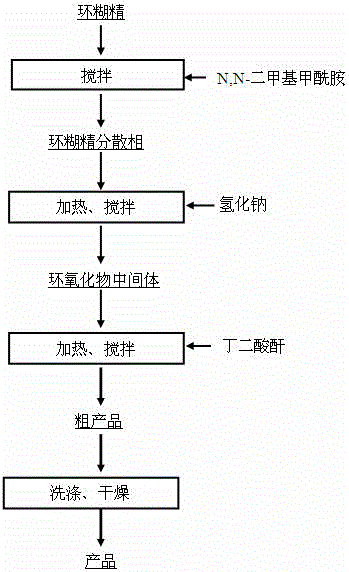

[0018] A chelating type metal ion flotation agent, its preparation process is as follows: with cyclodextrin, sodium hydride and succinic anhydride as raw materials, the amount ratio of the three substances is 1:5:5; first β-cyclodextrin Dissolved in anhydrous N,N-dimethylformamide, stirred for 10 min to obtain a cyclodextrin dispersed phase with a concentration of 5% (w / v, mass volume fraction), and then added to the cyclodextrin dispersed phase in proportion Sodium hydride, stirred at 30 °C for 12 h to obtain an epoxy intermediate; add succinic anhydride to the epoxy intermediate in proportion, and stir at 50 °C for 12 h; wash the obtained product with acetone and place it in a vacuum oven After drying at 50 °C for 24 h, the obtained solid is the chelating metal ion flotation agent.

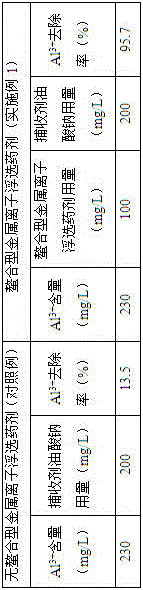

[0019] Use micro-bubble flotation column to process bauxite mineral processing wastewater, the chelating type metal ion flotation agent that embodiment 1 makes is added to Al 3+ In the high-con...

Embodiment 2

[0023] A chelating type metal ion flotation agent, its preparation process is as follows: with cyclodextrin, sodium hydride and succinic anhydride as raw materials, the amount ratio of the three substances is 1:5:5; first β-cyclodextrin Dissolve in anhydrous N,N-dimethylformamide and stir for 30 min to obtain a cyclodextrin dispersed phase with a concentration of 10% (w / v, mass volume fraction), and then add hydrogenated Sodium, stirred at 50 °C for 24 h to obtain an epoxy intermediate; add succinic anhydride to the epoxy intermediate in proportion, and stir at 70 °C for 24 h; wash the obtained product with acetone and place it in a vacuum oven for 50 After drying at ℃ for 24 h, the obtained solid is the chelating metal ion flotation agent.

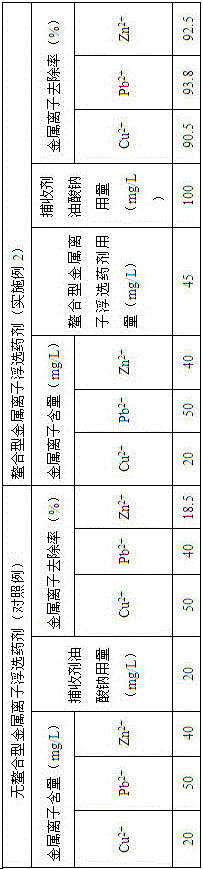

[0024] Use the micro-bubble flotation column to process the copper-lead-zinc ore dressing wastewater, and the chelated metal ion flotation agent of embodiment 2 is added to Cu 2+ , Pb 2+ , Zn 2+ In the low-concentration copper-lead-zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com