Biomimetic bone piezoelectric three-dimensional ceramic support material and preparation method and application thereof

A ceramic stent, piezoelectric ceramic technology, applied in medical science, tissue regeneration, prosthesis and other directions, to achieve the effect of easy promotion, good connectivity, controllable pore size and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a three-dimensional porous ceramic scaffold material imitating bone piezoelectricity, comprising the following steps:

[0034] (1) the mixture of the polyvinyl alcohol of 53 mass parts potassium sodium niobate ceramic powders, 35 mass parts sodium polypropionate solution (concentration of solution is 30wt%), 7 mass parts and glycerol (polyvinyl alcohol in the mixture The content is 15wt%), 5 parts by mass of sodium carboxymethylcellulose are mixed evenly to form a slurry, and finally a three-dimensional porous ceramic support with controllable size and shape is prepared by 3D printing technology;

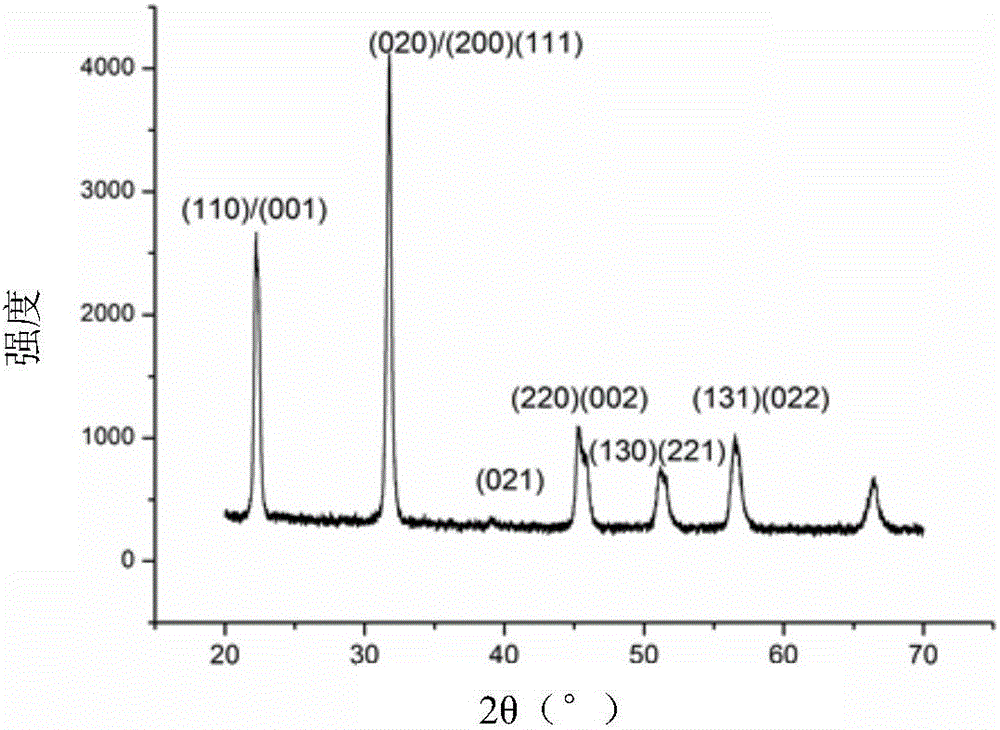

[0035] (2) Dry the three-dimensional porous ceramic scaffold obtained in step (1), sinter at 1000°C for 2 hours, and polarize at high voltage (the polarization voltage is 2kV, and the polarization treatment time is 5min), to obtain a three-dimensional bone-like piezoelectric structure. Porous ceramic scaffold material.

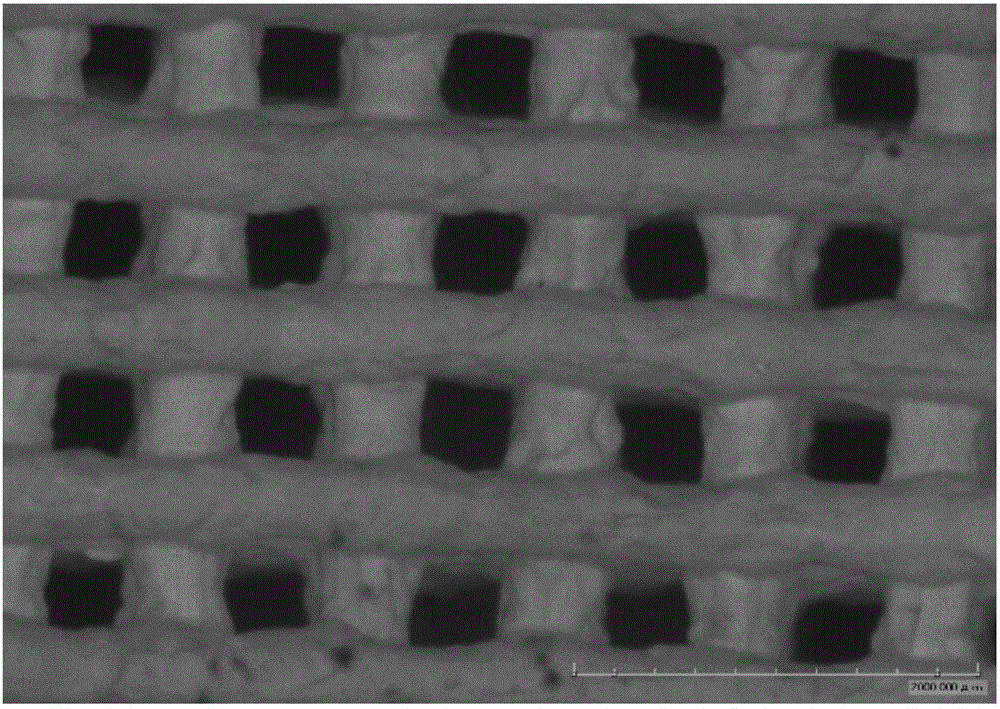

[0036] The pore size of the th...

Embodiment 2

[0038] A preparation method of a three-dimensional porous ceramic scaffold material imitating bone piezoelectricity, comprising the following steps:

[0039] (1) the mixture of the polyvinyl alcohol and glycerol of 46 mass parts potassium sodium niobate ceramic powders, 40 mass parts sodium polypropionate solution (concentration of solution is 30wt%), 10 mass parts (polyvinyl alcohol is in the mixture The content is 25wt%), 4 parts by mass of sodium carboxymethylcellulose are mixed evenly to form a slurry, and finally a three-dimensional porous ceramic support with controllable size and shape is prepared by 3D printing technology;

[0040] (2) Dry the three-dimensional porous ceramic scaffold obtained in step (1), sinter at 1000°C for 2 hours, and polarize at high voltage (the polarization voltage is 5kV, and the polarization treatment time is 5min), to obtain a three-dimensional bone-like piezoelectric structure. Porous ceramic scaffold material. The three-dimensional bone-i...

Embodiment 3

[0043] A preparation method of a three-dimensional porous ceramic scaffold material imitating bone piezoelectricity, comprising the following steps:

[0044] (1) the mixture of 47 mass parts potassium sodium niobate ceramic powder, 40 mass parts sodium polypropionate solution (concentration of solution is 30wt%), 10 mass parts polyvinyl alcohol and glycerol (polyvinyl alcohol in the mixture The content is 20wt%), 3 parts by mass of sodium carboxymethyl cellulose are mixed evenly to form a slurry, and finally a three-dimensional porous ceramic support with controllable size and shape is prepared by 3D printing technology;

[0045] (2) Dry the three-dimensional porous ceramic scaffold obtained in step (1), sinter at 1000°C for 2 hours, and polarize at high voltage (the polarization voltage is 5kV, and the polarization treatment time is 10min), to obtain a three-dimensional bone-like piezoelectric structure. Porous ceramic scaffold material. The pore size of the three-dimensiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com