A kind of hydrometallurgical recovery copper and cobalt method of copper cobalt slag

A technology of hydrometallurgy and copper recovery, which is applied in the field of hydrometallurgy recovery of copper and cobalt from copper-cobalt slag, which can solve the problems of large equipment investment and complicated production process, and achieve simple production process, low environmental pollution and low equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

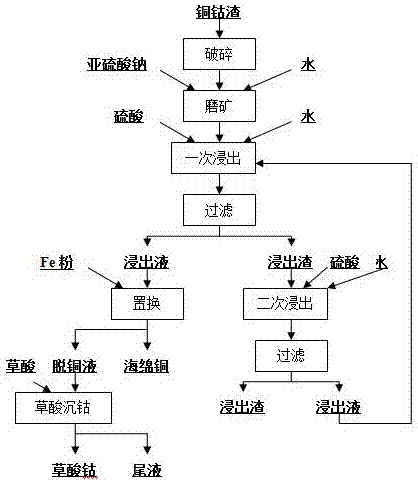

Method used

Image

Examples

Embodiment 1

[0017] A method for recovering copper and cobalt by hydrometallurgy of copper-cobalt slag, carried out according to the following steps:

[0018] (1) An imported copper-cobalt slag contains 13.52% copper and 4.79% cobalt. The copper-cobalt slag was crushed into fine particles below 3 mm, and then 100 g of copper-cobalt slag, 5 g of sodium sulfite and 100 g of water were weighed, and put into a wet ball mill for grinding for 10 minutes to obtain -325 mesh pulp with a fineness of 95%.

[0019] (2) Transfer all the above pulp to a beaker, add water to form a solid-liquid ratio of 1:3, add sulfuric acid with a mass fraction of 98% under stirring to make the initial acidity reach 20g / L, start stirring, and heat to 90°C in a water bath , keep warm for 1 hour, filter and wash while hot to obtain the copper-cobalt leaching solution, and leaching the slag once more before discarding.

[0020] (3) The leaching solution was neutralized with sodium carbonate to a pH value of 4, and 15 g ...

Embodiment 2

[0023] A method for recovering copper and cobalt by hydrometallurgy of copper-cobalt slag, carried out according to the following steps:

[0024] (1) An imported copper-cobalt slag contains 13.52% copper and 4.79% cobalt. The copper-cobalt slag was crushed into fine particles below 3 mm, and then 100 g of copper-cobalt slag, 10 g of sodium metabisulfite and 100 g of water were weighed and put into a wet ball mill for grinding for 10 minutes to obtain -325 mesh pulp with a fineness of 95%.

[0025] (2) Transfer all the above pulp to a beaker, add water to form a solid-liquid ratio of 1:3, add sulfuric acid with a mass fraction of 98% under stirring to make the initial acidity reach 20g / L, start stirring, and heat to 90°C in a water bath , keep warm for 1 hour, filter and wash while hot to obtain the copper-cobalt leaching solution, and leaching the slag once more before discarding.

[0026] (3) The leaching solution was neutralized with sodium carbonate to a pH value of 4, and...

Embodiment 3

[0029] A method for recovering copper and cobalt by hydrometallurgy of copper-cobalt slag, carried out according to the following steps:

[0030] (1) An imported copper-cobalt slag contains 13.52% copper and 4.79% cobalt. Break the copper-cobalt slag into fine particles below 3mm, then weigh 100g of copper-cobalt slag, 15g of sodium bisulfite and 100g of water, put them into a wet ball mill for grinding for 10min, and obtain -325 mesh pulp with a fineness of 95% .

[0031] (2) Transfer all the above pulp to a beaker, add water to form a solid-liquid ratio of 1:3, add sulfuric acid with a mass fraction of 98% under stirring to make the initial acidity reach 20g / L, start stirring, and heat to 90°C in a water bath , keep warm for 1 hour, filter and wash while hot to obtain the copper-cobalt leaching solution, and leaching the slag once more before discarding.

[0032] (3) Neutralize the leaching solution with sodium carbonate to a pH value of 4, add 17g of iron powder under sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com