Tomato controlled-release fertilizer

A technology of controlled-release fertilizer and tomato, applied in organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve the problems of affecting people's physical and mental health, short pesticide retention time, excessive pesticide residues, etc., to promote rapid and healthy growth, improve The effect of crop yield and dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

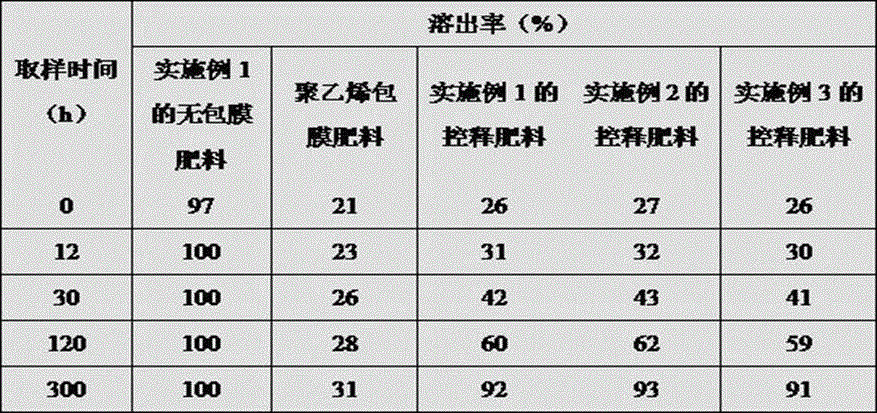

Image

Examples

preparation example Construction

[0063] The preparation method of described tomato controlled release fertilizer, comprises the following steps:

[0064] S1: Mix sheep manure, duck manure, pig manure, waste residue, earthworm powder, and biological bacteria evenly, ferment at 50-66°C for 17-27 days, let the fermentation liquid stand still and discard the sediment, and put the remaining fermentation liquid at 53- Concentrate at 62°C to obtain a concentrate;

[0065] S2: Add trace elements, water retaining agent, dispersant, and conditioning agent to the concentrate prepared in step S1, mix evenly and form particles with a particle size of 0.1-3.2mm, then dry at 82-104°C until the water content is ≤7%, Cool to room temperature to obtain fertilizer granules;

[0066] The preparation method of described conditioning agent, comprises the following steps:

[0067] S21: Set aside the acetic acid plant waste liquid for clarification to obtain a supernatant, then heat the supernatant to 67-82°C for evaporation and c...

Embodiment 1

[0085] A tomato controlled-release fertilizer, which is made of the following raw materials in parts by weight: 170 parts of fertilizer granules and 30 parts of coating;

[0086] The fertilizer granules are made of the following raw materials in parts by weight: 40 parts of sheep manure, 40 parts of duck manure, 35 parts of pig manure, 24 parts of waste residue, 17 parts of earthworm powder, 10 parts of biological bacteria, 1.5 parts of trace elements, 1.5 parts of water retaining agent, 1.5 parts of dispersant, 1.5 parts of conditioning agent;

[0087] The waste residue is sugar residue;

[0088] The biological bacteria are bacillus, saccharomyces, actinomycetes, phosphorus bacteria, potassium bacteria;

[0089] The trace element is made of the following raw materials in parts by weight: 0.3 parts of iron element, 0.3 part of boron element, 0.3 part of manganese element, 0.3 part of copper element, 0.2 part of zinc element, and 0.1 part of molybdenum element;

[0090] The w...

Embodiment 2

[0122] A tomato controlled-release fertilizer, which is made of the following raw materials in parts by weight: 102 parts of fertilizer granules and 20 parts of coating;

[0123] The fertilizer granules are made of the following raw materials in parts by weight: 20 parts of sheep manure, 20 parts of duck manure, 20 parts of pig manure, 12 parts of waste residue, 10 parts of earthworm powder, 4.8 parts of biological bacteria, 0.8 parts of trace elements, 0.8 parts of water-retaining agent, 0.8 parts of dispersant, and 0.8 parts of conditioning agent;

[0124] The waste residue is sugar residue;

[0125] The biological bacteria are bacillus, saccharomyces, actinomycetes, phosphorus bacteria, potassium bacteria;

[0126] The trace element is made of the following raw materials in parts by weight: 0.3 parts of iron element, 0.3 part of boron element, 0.3 part of manganese element, 0.3 part of copper element, 0.2 part of zinc element, and 0.1 part of molybdenum element;

[0127] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com