Slow-release fertilizer for Chinese yam and preparation method of slow-release fertilizer

A technology of slow-release fertilizers and fertilizer granules, applied in the direction of organic fertilizers, inorganic fertilizers, ammonium salt fertilizers, etc., can solve the problems of limited, low utilization rate of slow-release fertilizers, and slow slow-release effects, so as to achieve a wide range of sources and promote rapid health The effect of moderate growth and controlled release rate of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

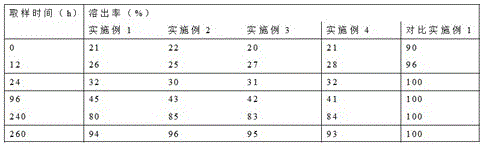

Examples

Embodiment 1

[0031] A Chinese yam slow-release fertilizer, the slow-release fertilizer is made of coating materials and fertilizer granules;

[0032] The coating material is made of the following raw materials in parts by weight: 30 parts of sodium alginate oligosaccharide, 10 parts of polyacrylamide, 3 parts of lignin, 5 parts of talcum powder, 0.1 part of glacial acetic acid, and 0.2 part of ammonium persulfate , 0.01 part of polypropylene glycol glycidyl ether and 0.05 part of coal tar;

[0033] The fertilizer granules are made of the following raw materials in parts by weight: 50 parts of urea, 80 parts of potassium sulfate, 40 parts of superphosphate, 40 parts of ammonium bicarbonate, 20 parts of sugar residue, 30 parts of potassium humate, earthworm powder 15 parts, chitosan 10 parts, diatomite 5 parts, iron boron manganese trace elements 5 parts and biological bacteria 0.5 parts.

[0034] The preparation method of above-mentioned Chinese yam slow-release fertilizer is:

[0035] 1)...

Embodiment 2

[0039] A Chinese yam slow-release fertilizer, the slow-release fertilizer is made of coating materials and fertilizer granules;

[0040] The coating material is made of the following raw materials in parts by weight: 70 parts of sodium alginate oligosaccharide, 5 parts of polyacrylamide, 8 parts of lignin, 1 part of talcum powder, 0.5 part of glacial acetic acid, and 0.1 part of ammonium persulfate , 0.05 parts of polypropylene glycol glycidyl ether and 0.01 parts of coal tar;

[0041] The fertilizer granules are made of the following raw materials in parts by weight: 100 parts of urea, 45 parts of potassium sulfate, 60 parts of superphosphate, 25 parts of ammonium bicarbonate, 40 parts of sugar residue, 20 parts of sodium humate, earthworm powder 25 parts, 5 parts of chitosan, 10 parts of diatomaceous earth, 3 parts of copper trace elements and 3 parts of biological bacteria.

[0042] The preparation method of above-mentioned Chinese yam slow-release fertilizer is:

[0043]...

Embodiment 3

[0047] A Chinese yam slow-release fertilizer, the slow-release fertilizer is made of coating materials and fertilizer granules;

[0048] The coating material is made of the following raw materials in parts by weight: 45 parts of sodium alginate oligosaccharide, 8 parts of polyacrylamide, 6 parts of lignin, 3 parts of talcum powder, 0.3 part of glacial acetic acid, and 0.1 part of ammonium persulfate , 0.05 parts of aziridine and 0.01 parts of polyethylene wax;

[0049] The fertilizer granules are made of the following raw materials in parts by weight: 65 parts of urea, 65 parts of potassium sulfate, 50 parts of superphosphate, 30 parts of ammonium bicarbonate, 40 parts of edible fungus residue, 20 parts of potassium fulvic acid, earthworm Powder 25 parts, chitosan 5 parts, diatomite 10 parts, zinc molybdenum strontium and selenium trace elements 5 parts and biological bacteria 2 parts.

[0050] The preparation method of above-mentioned Chinese yam slow-release fertilizer is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com