A special impact-resistant polymer rapid repair material for rapid bridge deck paving

A repair material and impact-resistant technology, which is applied in the field of impact-resistant polymer rapid repair materials for rapid bridge deck paving, and can solve the problems of slow concrete setting time, poor interface bonding performance, and long curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

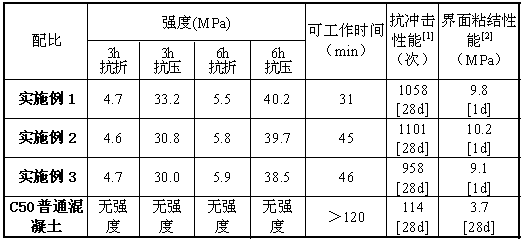

Embodiment 1

[0023] Example 1 A special impact-resistant polymer quick-repair material for bridge deck rapid pavement, the material component A and component B are mixed by weight (kg); wherein

[0024] Component A is made by mixing the following raw materials in parts by weight (kg): 65 parts of basic cementitious material, 0.3 part of water reducer, 0.6 part of coagulation regulator, 0.1 part of anti-crack fiber, and 24 parts of quartz sand;

[0025] Component B refers to 10 parts of toughening agent.

Embodiment 2

[0026] Example 2 A special impact-resistant polymer rapid repair material for bridge deck rapid pavement, the material component A and component B are mixed by weight (kg); wherein

[0027] Component A is made by mixing the following raw materials in parts by weight (kg): 65 parts of basic cementitious material, 0.3 part of water reducer, 0.7 part of coagulation regulator, 0.1 part of anti-crack fiber, and 23.9 parts of quartz sand;

[0028] Component B refers to 10 parts of toughening agent.

Embodiment 3

[0029] Example 3 A special impact-resistant polymer rapid repair material for bridge deck rapid pavement, the material component A and component B are mixed by weight (kg); wherein

[0030] Component A is made by mixing the following raw materials in parts by weight (kg): 65 parts of basic cementitious material, 0.3 part of water reducer, 0.7 part of coagulation regulator, 0.12 part of anti-crack fiber, and 23.88 parts of quartz sand;

[0031] Component B refers to 10 parts of toughening agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com