Catalyst for two-step methanol to gasoline alkylation and preparation method thereof

A methanol-to-gasoline and catalyst technology, which is applied in the preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of catalyst deactivation, short catalyst single-pass life, low selectivity, etc., and achieve gasoline selectivity High, stable performance, and the effect of improving catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

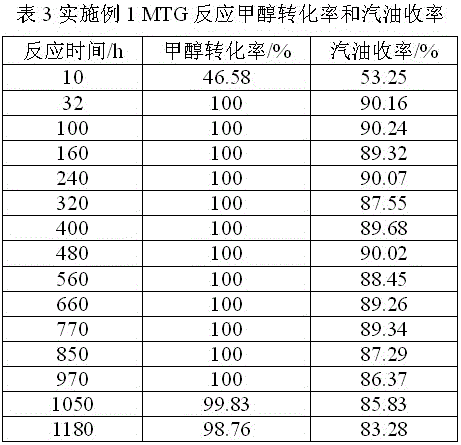

Embodiment 1

[0025] A kind of preparation method of the catalyst that two-step process methanol is used for gasoline alkylation comprises the following steps:

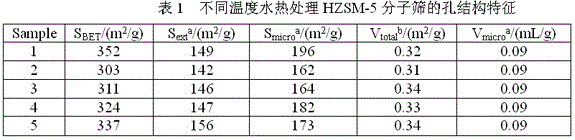

[0026] 1) Add NaZSM-5 molecular sieve with a molar ratio of silicon to aluminum of 100 into 0.2mol / L ammonium chloride solution, stir evenly, the solid-liquid ratio is 1:10, exchange ammonium at 90°C for 2 hours, wash with water, and After drying at 120°C for 5 hours, calcining at 650°C for 6 hours to obtain HZSM-5 molecular sieve, and then performing hydrothermal treatment at 400°C for 3 hours, then cooling to room temperature, the liquid phase mass space velocity of water is 1h -1 ;

[0027] 2) At 80°C, add the molecular sieve obtained in step 1) into an acid solution with a molar concentration of 1mol / L for pickling, the solid-to-liquid ratio is 1:10, after immersion for 4 hours, suction filtration, deionized water washing, suction filtration, Calcined at 600°C for 4 hours to obtain acid-washed HZSM-5 molecular sieve;

[0028]...

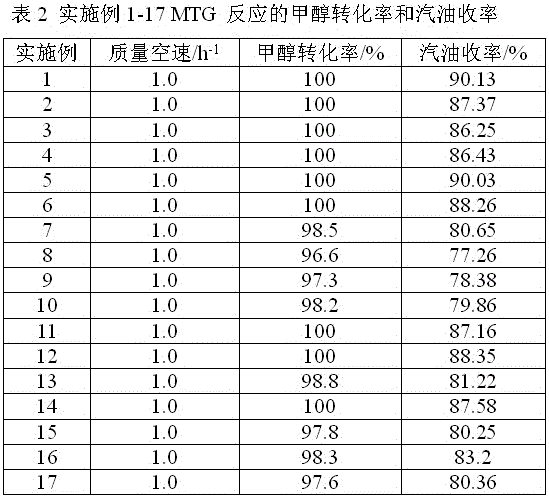

Embodiment 2-4

[0031] The solutions containing active metal additives in step 4) of Examples 2-4 are respectively: ferric nitrate solution, ammonium molybdate solution, and nickel nitrate solution of the same concentration, and others refer to Example 1.

Embodiment 5-6

[0033] The acid solutions in step 2) in Example 5-6 are respectively 1 mol / L nitric acid and molybdic acid, and others refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com