Aluminum-containing film layer pattern, manufacturing method and post processing method therefor

A production method and film layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effect of shortening the processing time, saving waiting time, and prolonging the cycle of daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

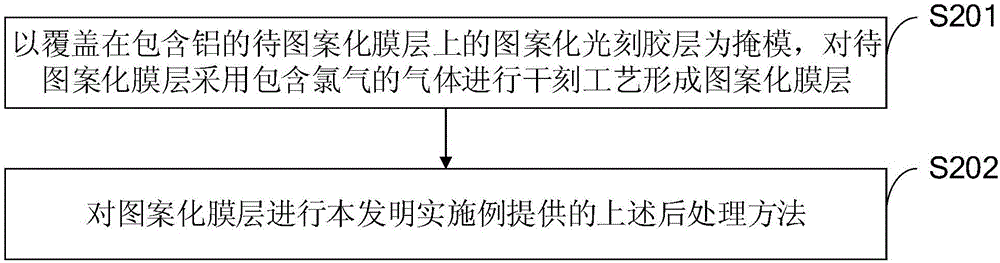

[0028] The specific implementation manners of the aluminum-containing film layer pattern provided by the embodiments of the present invention, its manufacturing method and its post-processing method will be described in detail below with reference to the accompanying drawings.

[0029] Specifically, due to the use of chlorine gas (Cl 2 ) gas, therefore, after dry etching, there will be residual chlorine gas on the surface of the patterned film layer containing aluminum (Al), and the metal aluminum in the patterned film layer will absorb the residual chlorine gas and carry out the following reaction : 2Al+3Cl 2 →2AlCl 3 ↑.

[0030] Therefore, if the dechlorination treatment is not carried out, when the patterned film layer is exposed to the air, the residual chlorine reacts with the metal aluminum in the patterned film layer to generate AlCl 3 Reacts with moisture in the atmosphere to form HCl. HCl will react with Al to form Al x Cl y . Al x Cl y Then react with moistu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com