Organic polysilazane/inorganic nano-material super-hydrophobic coating and preparation method thereof

A technology of inorganic nanomaterials and super-hydrophobic coatings, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of difficult removal of catalysts, research and application limitations, cumbersome processes, etc., and achieve good mechanical and chemical stability, The effect of widening the application field and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

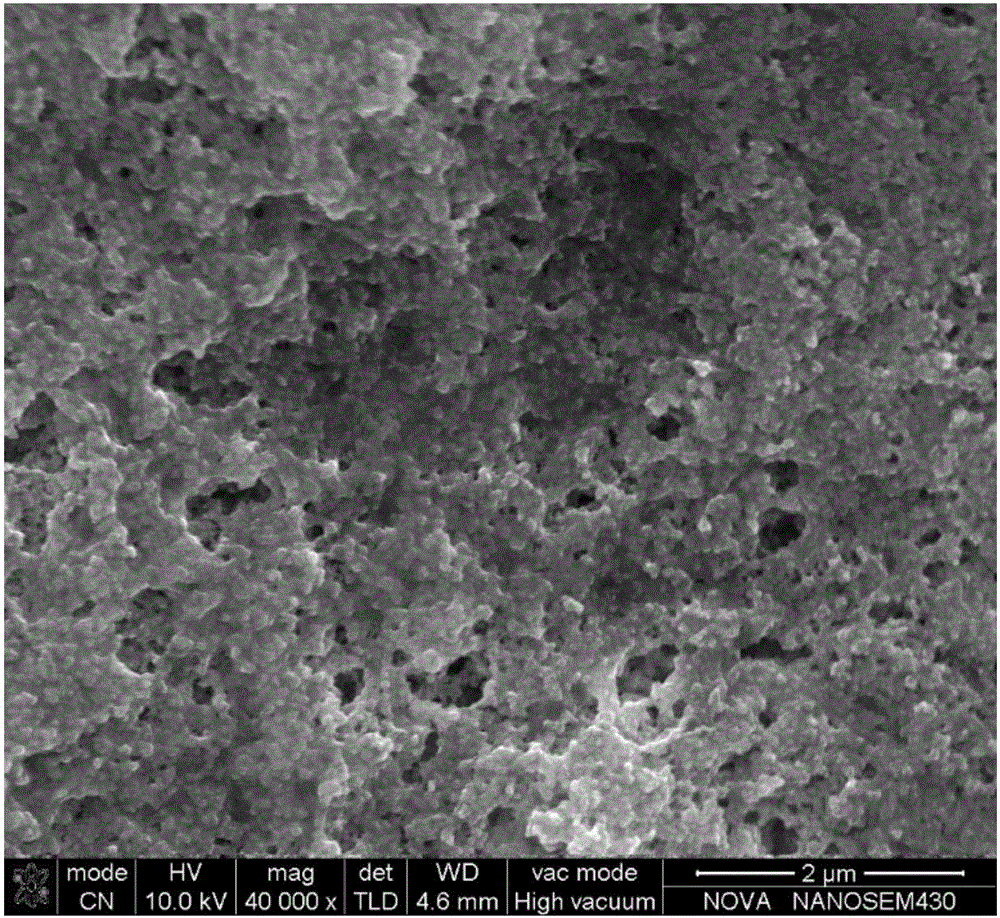

[0034] (1) Preparation of hydrophobic inorganic nanomaterial dispersion: 1.0g SiO 2 Nanoparticles were ultrasonically dispersed in 4.0 g of absolute ethanol to obtain SiO with a mass fraction of 20 wt%. 2 Dispersion; add 0.4 g heptadecafluorodecyltriethoxysilane and 2.0 g isopropyl orthosilicate to SiO 2 In the dispersion liquid, adjust its pH value to 8 by adding ammonia water; react at 30°C for 36 hours to obtain hydrophobic SiO 2 nanoparticle dispersion.

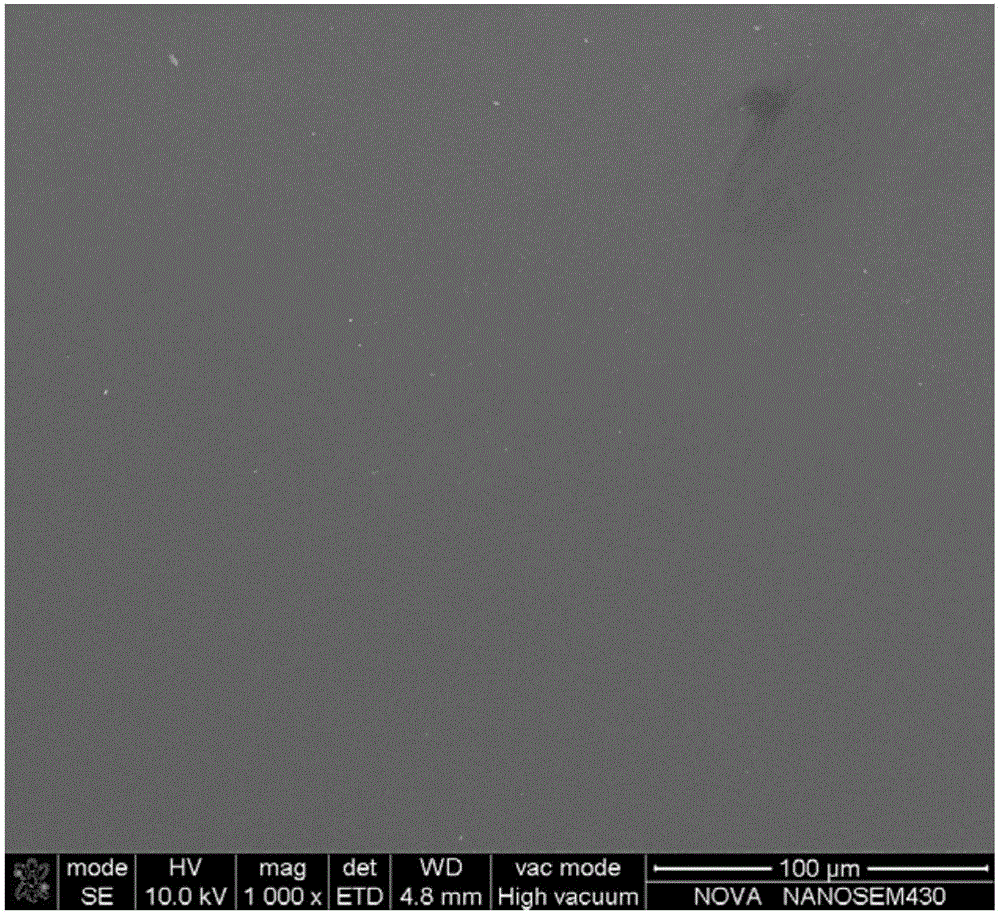

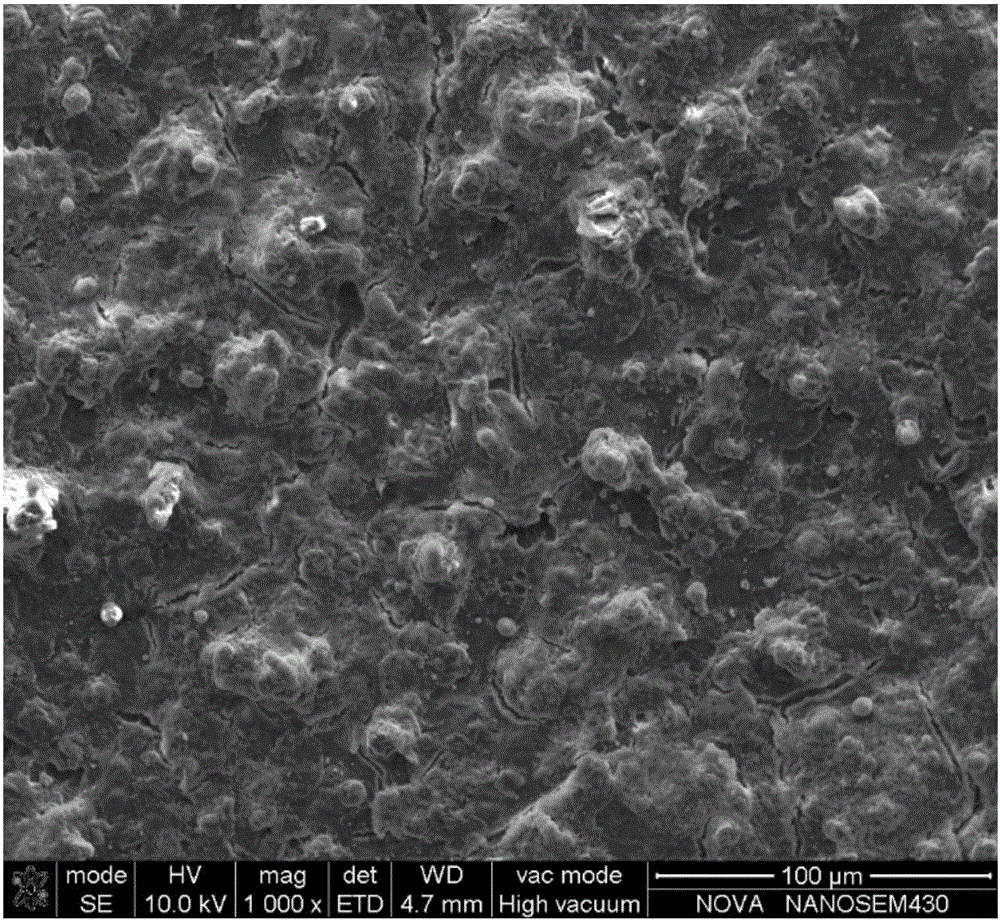

[0035] (2) Preparation of organopolysilazane / inorganic nanomaterial layer-by-layer superhydrophobic coating: dissolve organopolysilazane in tetrahydrofuran to obtain a tetrahydrofuran solution containing 10wt% organopolysilazane; then, Spray 2.0mL of tetrahydrofuran solution of organopolysilazane on the glass surface, and after the solvent evaporates, spray 2.0mL of hydrophobic SiO on the surface 2 Nanoparticle dispersion; take the above spraying process as a cycle, repeat this cycle 5 times; finally, heat-cure the obt...

Embodiment 2

[0043] (1) Preparation of hydrophobic inorganic nanomaterial dispersion: ultrasonically disperse 0.1g graphene oxide in 9.9g propylene glycol to obtain a graphene oxide dispersion with a mass fraction of 0.1wt%; Oxysilane and 10.0 g of butyl orthosilicate were added to the graphene oxide dispersion, and the pH was adjusted to 12 by adding ammonia water; reacted at 50° C. for 20 hours to obtain a hydrophobic graphene oxide dispersion.

[0044] (2) Preparation of organopolysilazane / organopolysilazane / inorganic nanomaterial layer-by-layer assembly of superhydrophobic coating: dissolve organopolysilazane in dimethyl sulfoxide to obtain dimethyl sulfoxide containing 12wt% organopolysilazane sulfoxide solution; then, spin-coat 2.0mL organopolysilazane dimethyl sulfoxide solution on the surface of the PET film, and then spin-coat 2.0mL hydrophobic graphene oxide dispersion on the surface after the solvent evaporates ; take the above spin coating process as a cycle, repeat this cycle ...

Embodiment 3

[0050] (1) Preparation of hydrophobic inorganic nanomaterial dispersion: ultrasonically disperse 1.5g montmorillonite in 1.0g isopropanol to obtain a montmorillonite dispersion with a mass fraction of 60wt%; Ethoxysilane and 1.5 g of propyl orthosilicate were added to the montmorillonite dispersion, and the pH was adjusted to 9 by adding ammonia water; reacted at 60° C. for 12 hours to obtain a hydrophobic montmorillonite dispersion.

[0051] (2) Preparation of organopolysilazane / inorganic nanomaterial layer-by-layer superhydrophobic coating: dissolve organopolysilazane in butyl acetate to obtain a butyl acetate solution containing 40wt% organopolysilazane Then, the butyl acetate solution of 2.0mL organopolysilazane is scraped on the surface of the copper sheet, and after the solvent volatilizes, further scrape the hydrophobic montmorillonite dispersion of 2.0mL on its surface; with the above-mentioned scraping process One cycle is repeated once; finally, the obtained coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com