LED optical stimulation and electrographic recording integrating flexible neural electrode device and manufacturing method thereof

A technology of recording electrodes and stimulating electrodes, which is applied in the field of micro-electrodes in the field of biomedical engineering technology, can solve the problems that the relative position of LED light source and recording electrodes cannot be guaranteed, and has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

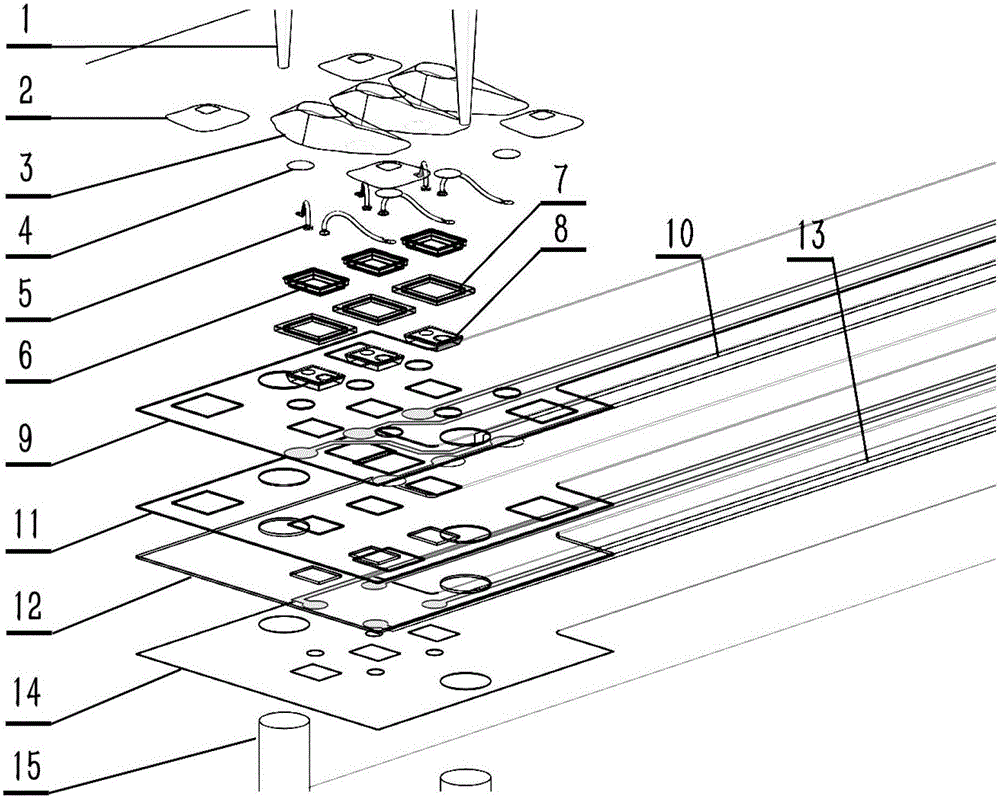

[0109] Such as figure 1 As shown, this embodiment provides a flexible nerve electrode device integrated with LED light stimulation and electrical recording, which is composed of light stimulation electrodes and recording electrodes;

[0110] The photo-stimulation electrode includes: a polyimide insulating layer 9 on the top layer of the photo-stimulation electrode, a metal layer 10 in the middle of the photo-stimulation electrode, and a polyimide insulating layer 11 at the bottom of the photo-stimulation electrode, wherein: the polyimide insulating layer on the top layer of the photo-stimulation electrode The amine insulating layer 9 and the bottom polyimide insulating layer 11 of the photo-stimulation electrode are provided with overlapping rectangular holes, circular holes and square holes, which are respectively used to ensure the light transmission of the micro-LED bare chip 8 and pass through the steel needle 1 and the Apply epoxy resin glue 2 to fix the relative position...

Embodiment 2

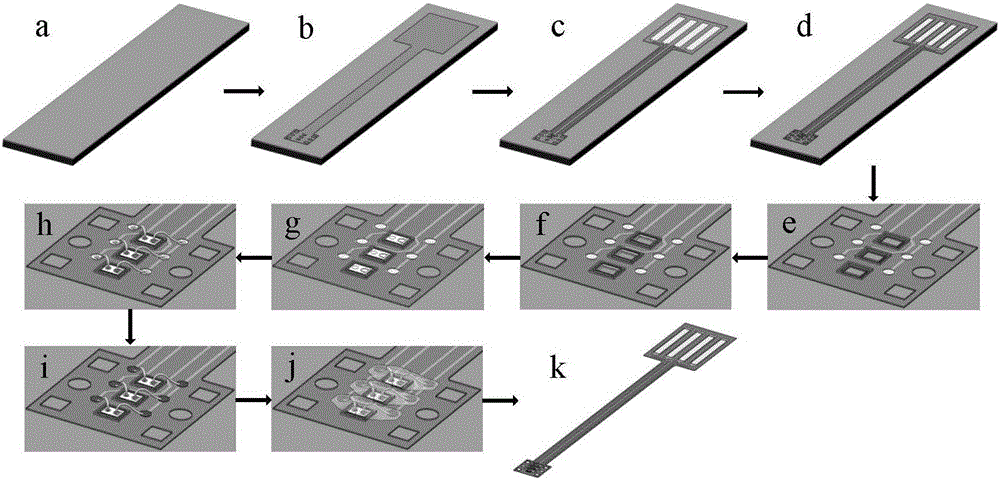

[0116] Such as Figure 2-Figure 4 As shown, this embodiment provides a method for preparing a flexible neural electrode device integrated with LED light stimulation and electrical recording, including:

[0117] 1. The preparation of photostimulation electrodes is carried out according to the following steps:

[0118] 1) if figure 2 As shown in middle a, a layer of 500 micron thick aluminum is deposited as a sacrificial layer on a 500 micron thick silicon wafer by sputtering or thermal evaporation;

[0119] 2) if figure 2 As shown in middle b, a layer of photosensitive polyimide Durimide 7510 is spin-coated, and after pre-baking, exposure, development and curing, a patterned polyimide insulating layer at the bottom of the photo-stimulation electrode is produced, and its thickness is 10 microns; There are three rectangular holes on the polyimide insulating layer at the bottom of the photo-stimulation electrode. There are two circular holes with a diameter of 300 microns an...

Embodiment 3

[0147] This embodiment provides a method for preparing a flexible nerve electrode device integrated with LED light stimulation and electrical recording similar to that of Embodiment 1, including:

[0148] 1. The preparation of photostimulation electrodes is carried out according to the following steps:

[0149] 1) Thermally evaporate a layer of 1.0 mm thick aluminum on a 500 micron thick silicon wafer as a sacrificial layer;

[0150] 2) Spin-coat a layer of photosensitive polyimide Durimide 7505, and through pre-baking, exposure, development and curing, make a patterned photo-stimulation electrode bottom polymer insulating layer 11 with a thickness of 5 microns; There are 3 rectangular holes on the bottom polymer insulating layer 11, the size of the rectangular holes is 190 microns × 270 microns, and the center distance is 700 microns; there are 2 circular holes on the bottom polymer insulating layer 11 of the photo-stimulation electrode, The circular hole has a diameter of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com