Preparation method of porous titanium/carbon niobate composite microsphere

A porous niobium and carbon composite technology, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of harsh preparation conditions, high production costs, and complicated preparation processes, and achieve simple methods, short preparation cycles, and improved The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

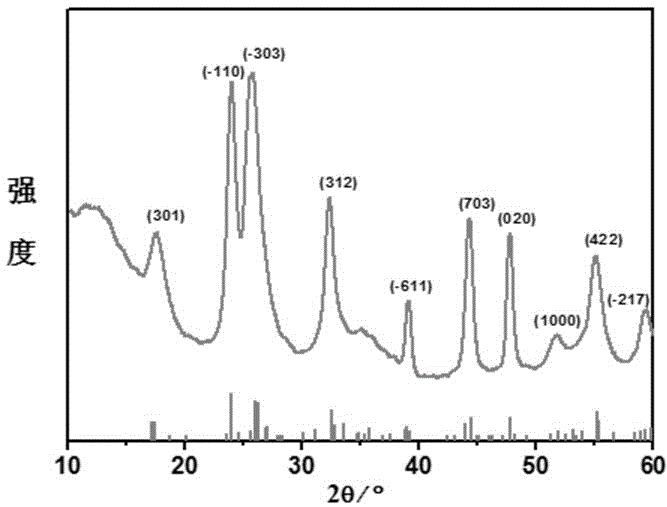

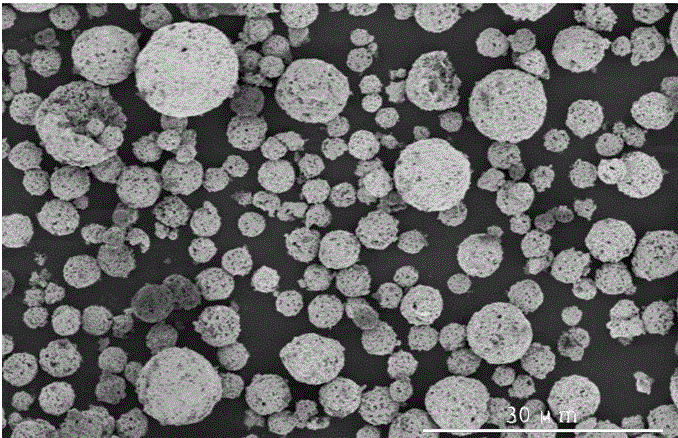

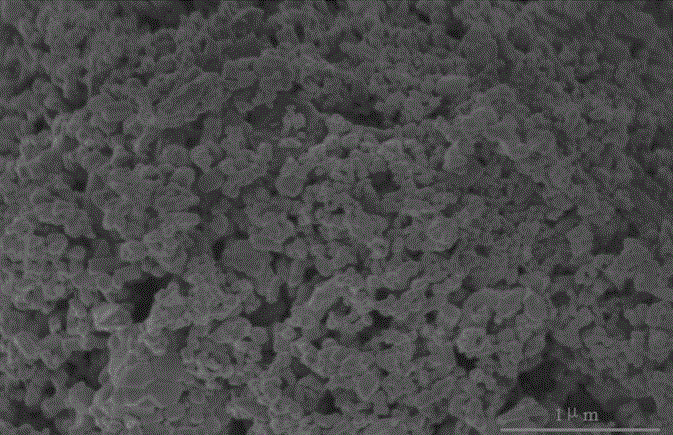

Embodiment 1

[0019] Weigh 26.6 g of niobium pentoxide, 8.0 g of titanium dioxide, and 345 ml of deionized water, pour them into ball mill jars, and then add 400 g of ball mills. Ball milled at 300 r / min for 10 h to obtain a suspension with good dispersibility. Dissolve 400 mg of sucrose in 20 ml of deionized water and stir magnetically for 2 h to obtain a clear sucrose solution. The clear solution was poured into the suspension, and ball milled at a speed of 6000 r / min for 6 h to obtain a suspension with good dispersibility. Transfer the suspension to a 500ml beaker, place it in an ultrasonic cleaner for ultrasonic dispersion, and then set up the spray drying program: the speed of the peristaltic pump is 35 rpm, the diameter of the nozzle is 1 mm, the air inlet temperature is 200 °C, and the needle is 5 times / min, fan speed 25 m 3 / h, finally start the spray drying program to carry out the spray drying experiment, collect the sprayed titanium niobate precursor powder, and transfer it to ...

Embodiment 2

[0021] Weigh 26.6 g of niobium pentoxide, 8.0 g of titanium dioxide, and 340 ml of deionized water, pour them into ball mill jars, and then add 410 g of ball mills. After ball milling at 350 r / min for 12 h, a suspension with good dispersibility was obtained. Dissolve 405 mg of sucrose in 21 ml of deionized water and stir magnetically for 2.5 h to obtain a clear sucrose solution. The clear solution was poured into the suspension, and ball milled at a speed of 6000 r / min for 6.5 h to obtain a suspension with good dispersibility. Transfer the suspension to a 500 ml beaker; then, place the beaker in an ultrasonic cleaner for ultrasonic dispersion, and then set the spray drying program: peristaltic pump speed 30 rpm, nozzle diameter 1 mm, air inlet temperature 220 ℃, 6 needle passes / min, fan speed 20 m 3 / h, finally start the spray drying program to carry out the spray drying experiment, collect the sprayed titanium niobate precursor powder, and transfer it to the sample bag for ...

Embodiment 3

[0023] Weigh 26.6 g of niobium pentoxide, 8.0 g of titanium dioxide, and 345 ml of deionized water, pour them into ball mill jars, and then add 410 g of ball mills. Ball milled at 250 r / min for 10 h to obtain a suspension with good dispersibility. Dissolve 400 mg of sucrose in 21 ml of deionized water and stir magnetically for 2 h to obtain a clear sucrose solution. The clear solution was poured into the suspension, and ball milled at a speed of 6000 r / min for 6.5 h to obtain a suspension with good dispersibility. Transfer the suspension to a 500 ml beaker; then, place the beaker in an ultrasonic cleaner for ultrasonic dispersion, and then set the spray drying program: peristaltic pump speed 45 rpm, nozzle diameter 0.7 mm, air inlet temperature 220 ℃, 7 needle passes / min, fan speed 30 m 3 / h, finally start the spray drying program to carry out the spray drying experiment, collect the sprayed titanium niobate precursor powder, and transfer it to the sample bag for future use....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com