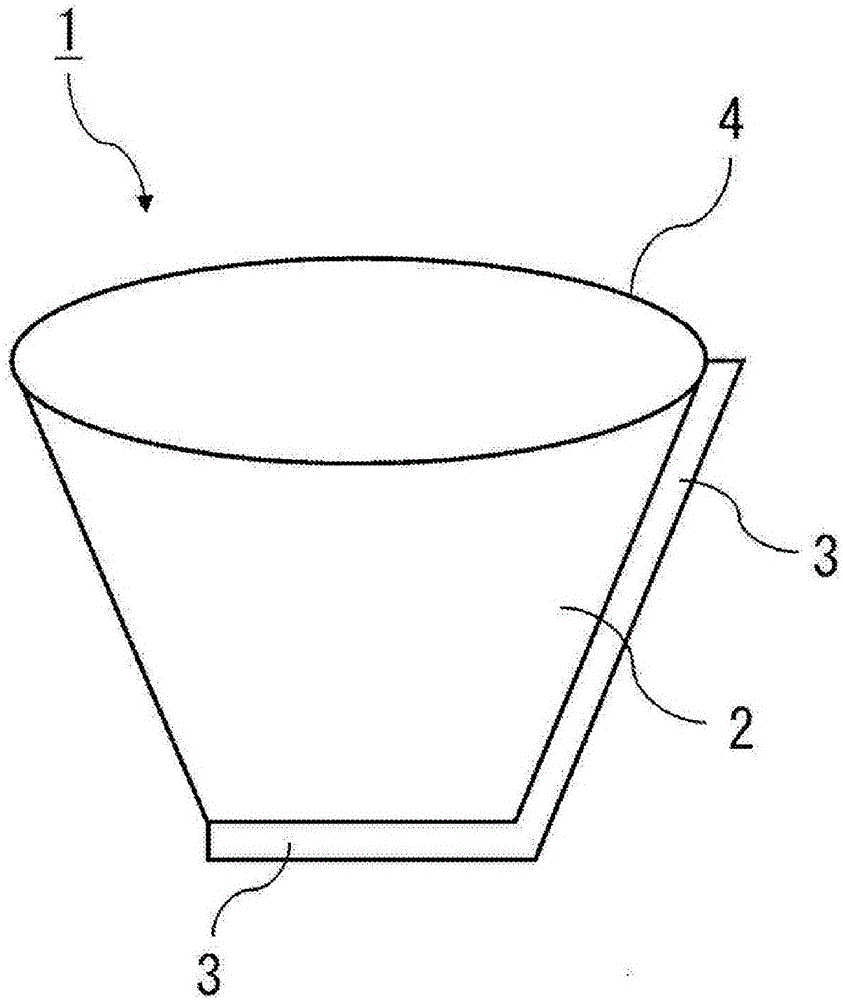

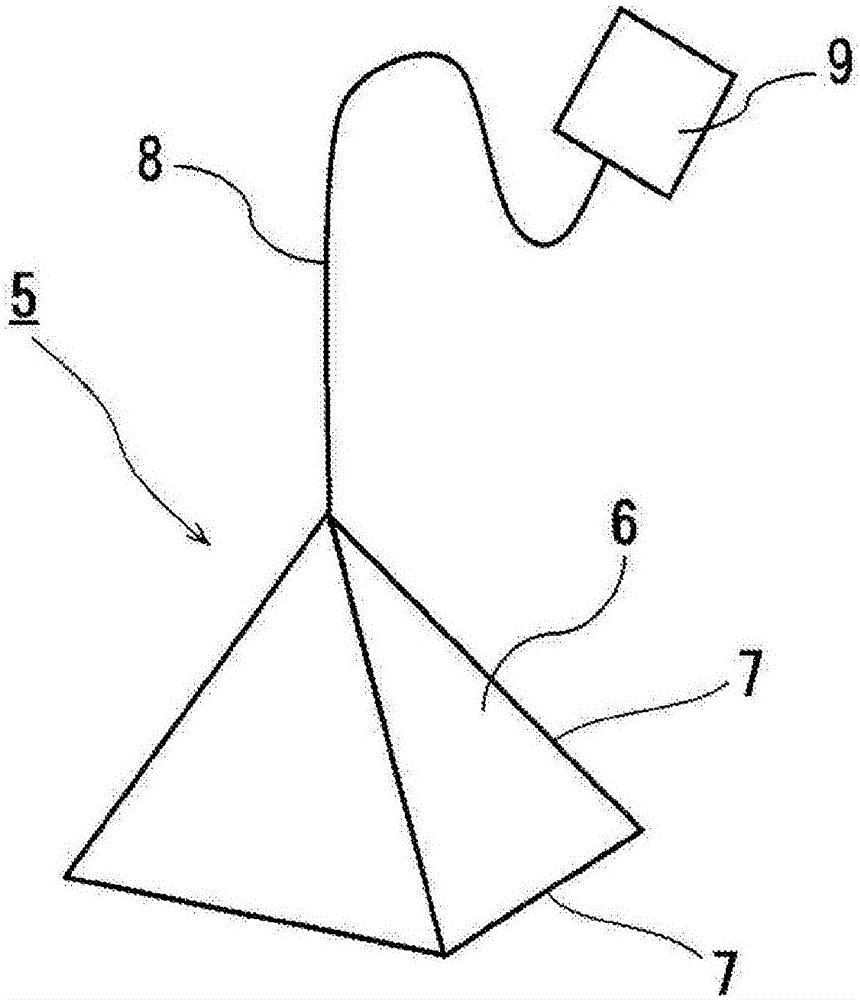

Nonwoven fabric sheet, and extraction-use filter and extraction-use bag using same

一种无纺布、纺粘无纺布的技术,应用在膜过滤器、固定式滤芯过滤器、过滤分离等方向,能够解决无法得到充分拉伸强度、热压接处理不完全、大密封强度等问题,达到透明性和提取性优异、形态保持性优异、大密封强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

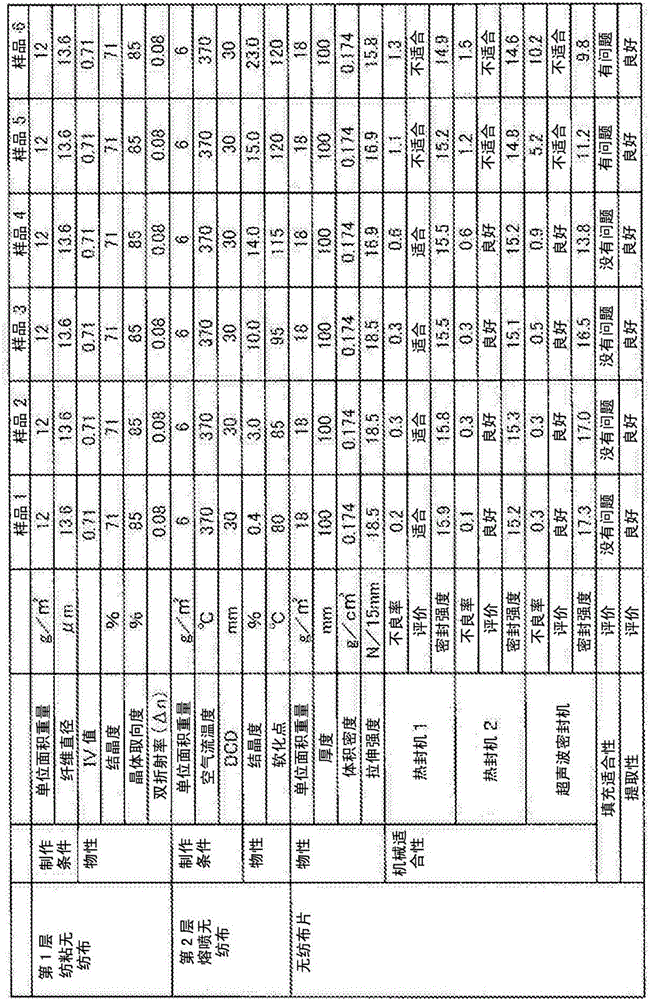

[0139] Using the spun-bonding method, the polyethylene terephthalate resin is heated and melted and spun out from a spinning nozzle with a diameter of 0.3 mm, stretched / fiber-opened with a jet at a spinning speed of 5000 m / min, and collected into a tape A web was formed on a type conveyor, and a partial thermocompression bonding process with a thermocompression bonding area ratio of 15% was performed to produce a spunbonded nonwoven fabric of the first layer. The weight per unit area of gained spunbond nonwoven fabric is 12.0g / m 2 , The fiber diameter is 13.6 μm, the IV value of the resin is 0.71, the degree of crystallinity is 71%, the degree of crystal orientation is 85%, and the birefringence (Δn) is 0.080.

[0140] Next, on the surface of the spun-bonded non-woven fabric, a polyester resin having a terephthalic acid / isophthalic acid polymerization ratio of 86 / 14 as an acid component was used, and the temperature of the air stream was set to 370°C. The distance (DCD) fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| orientation degree | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com